Two-phase multi-material online injection water-plugging profile regulating method and equipment

A water plugging profile control and multi-material technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of huge facilities, difficult control of injection volume, and inflexible adjustment of injection mechanism, so as to reduce energy consumption. Consumption, reduce the effect of production labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

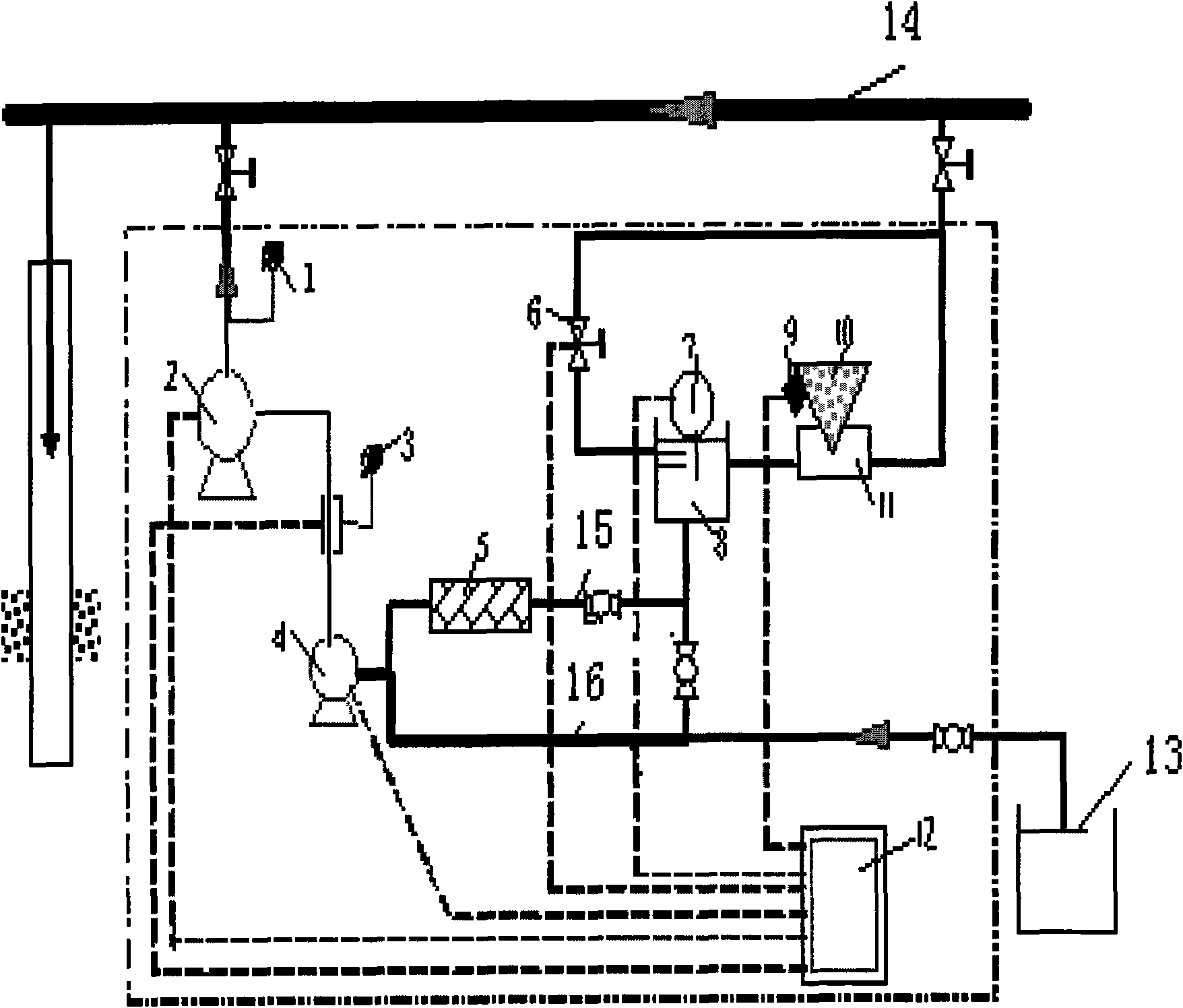

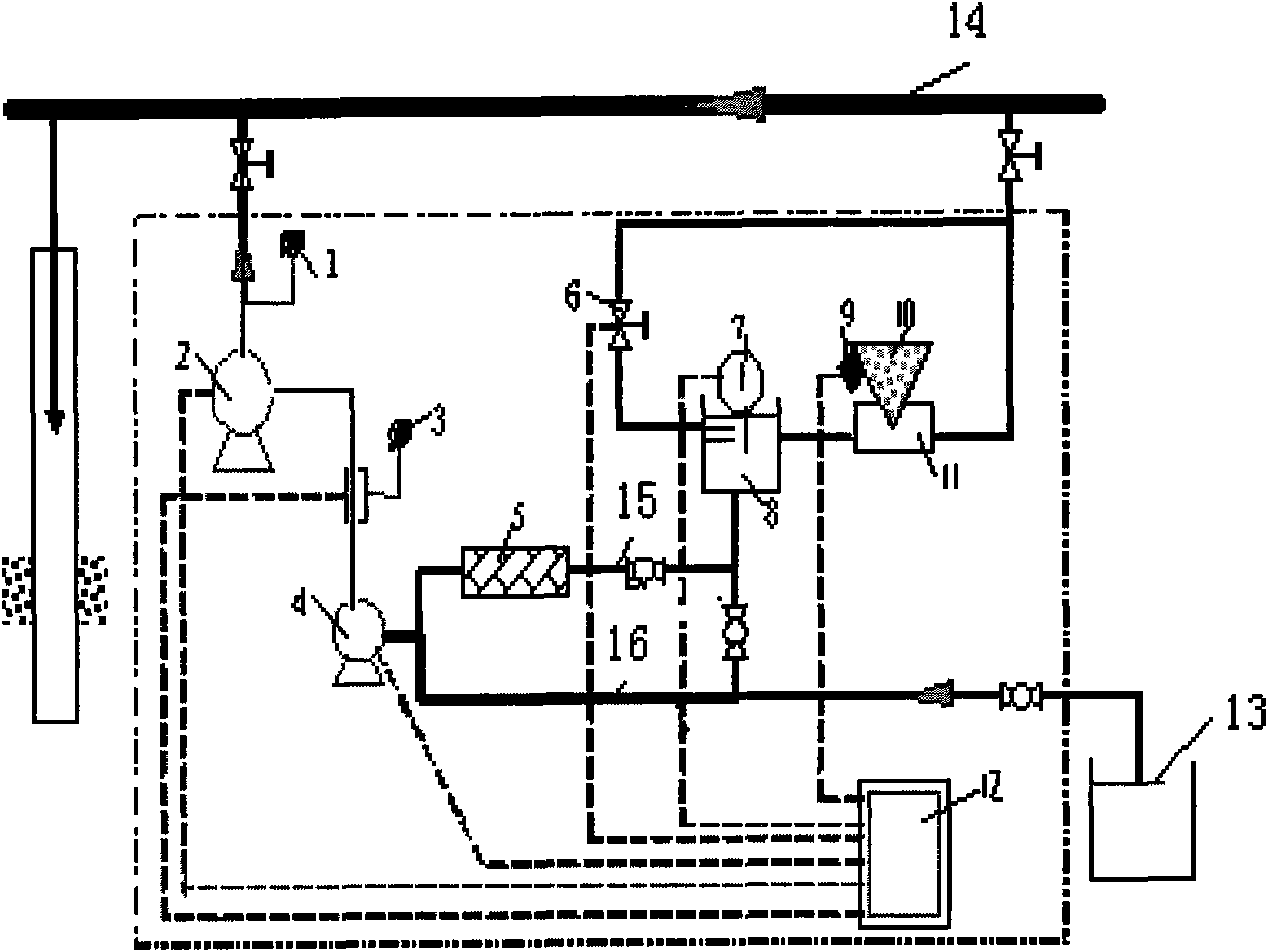

[0012] refer to figure 1 . The two-phase multi-material online injection water blocking profile control process equipment of the present invention consists of a pressure gauge 1, a high-pressure plunger pump 2, a flow meter 3, a self-priming pump 4, a static mixer 5, a solenoid valve 6, and a liquid level controller. 7. Buffer tank 8, vibrator 9, hopper 10, ejector 11, control cabinet 12, liquid storage tank 13, high-pressure water injection pipeline 14, pipeline one 15, pipeline two 16; the liquid storage tank passes through pipeline two 16 Connected with self-priming pump 4, the liquid level in liquid storage tank 13 is lower than the suction port of self-priming pump 4; connection; a vibrator 9 and a hopper 10 are installed above the ejector 11, one end of the ejector 11 is connected to the high-pressure water injection pipeline 14 through a pipeline, and the other end is connected to the buffer tank 8; the liquid level controller 7 is located on the liquid surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com