Method for controlling and reducing thermal load of internal combustion engine

A technology for internal combustion engines, thermal loads, applied in the direction of internal combustion piston engines, combustion engines, cooling of engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

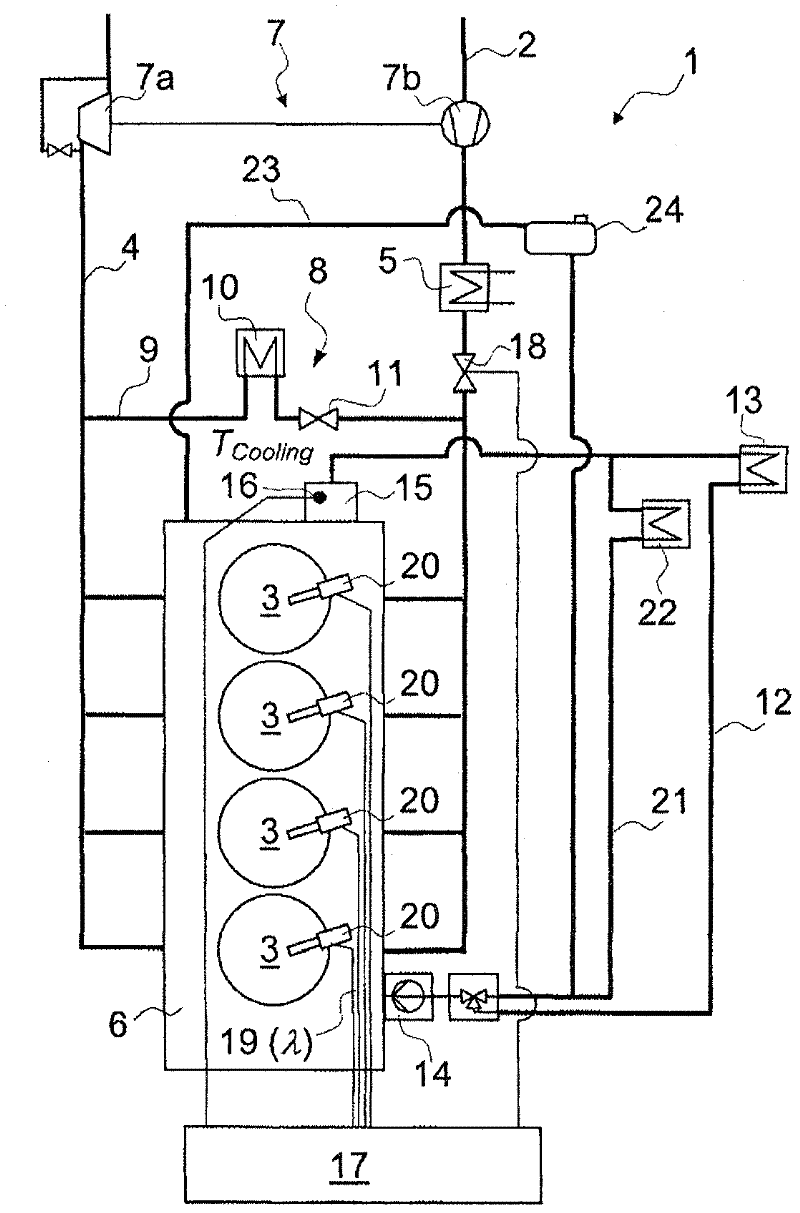

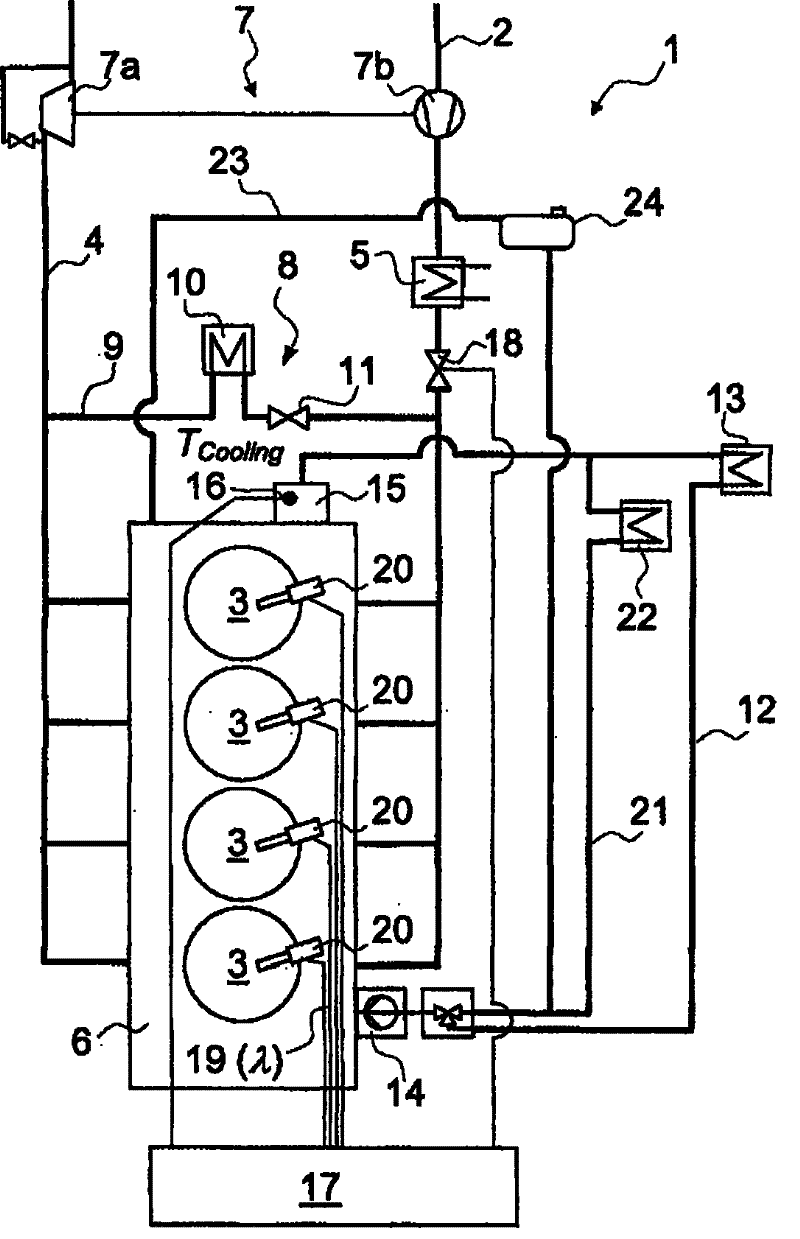

[0125] figure 1 A first embodiment of an internal combustion engine 1 implementing a method of limiting thermal load is schematically shown.

[0126] The internal combustion engine is a direct-injected four-cylinder in-line engine 1 , in which four cylinders 3 are arranged along the longitudinal axis of the cylinder head 6 , ie arranged in-line, and are equipped in each case with injectors 20 for injecting fuel. The injectors 20 are independently actuated, ie controlled, by the engine controller 17 via the control line 19 . The injected fuel quantity is used to set the air ratio λ.

[0127] The exhaust line 4 is used to expel hot combustion gases, and the intake line 2 is used to supply fresh air or a fresh mixture to the cylinder 3 . In order to adjust the load, a throttle valve 18 is provided in the intake line 2 as a closing element, which throttle valve 18 can likewise be controlled and / or adjusted by the engine controller 17 .

[0128] For charging purposes, the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com