CMK-5 type mesoporous carbon-nano inorganic substance composite material, preparation method and application thereof

A nano-inorganic substance, CMK-5 technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of promoting cycle stability, stable cycle performance, and small swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

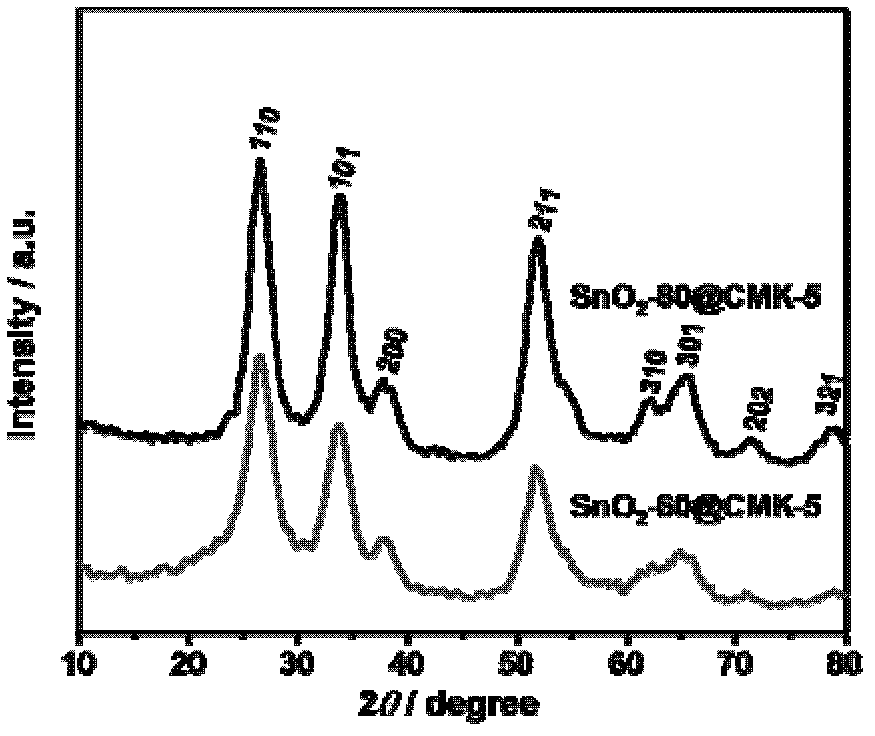

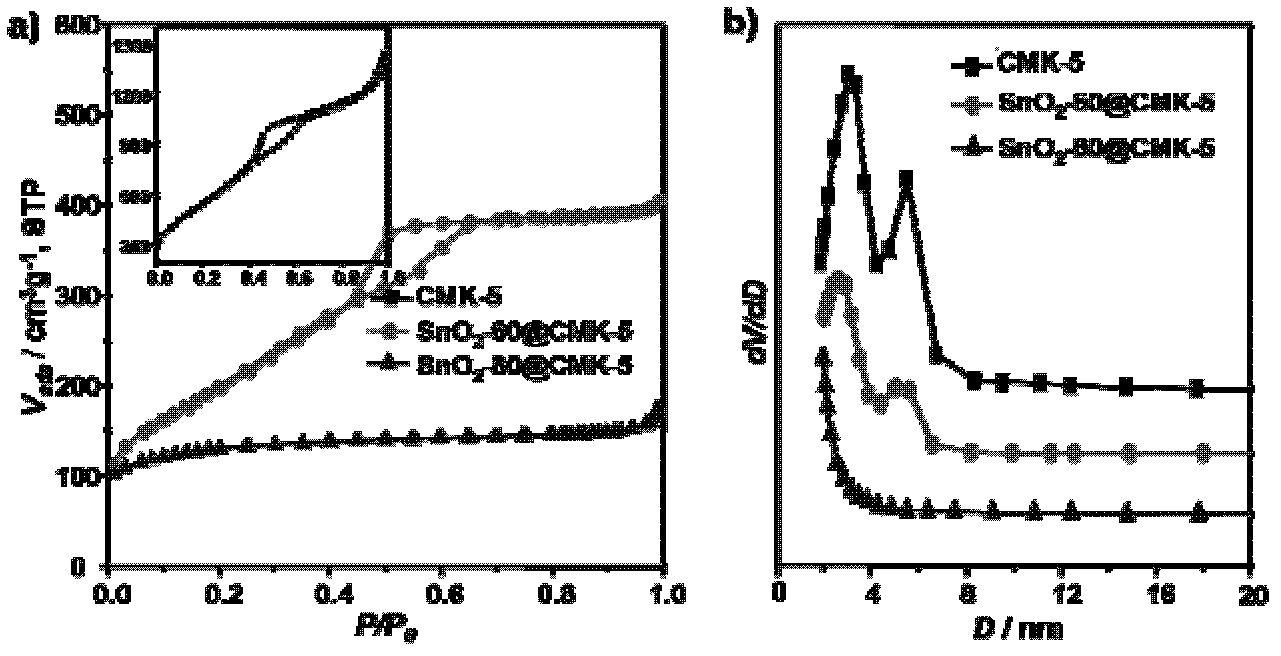

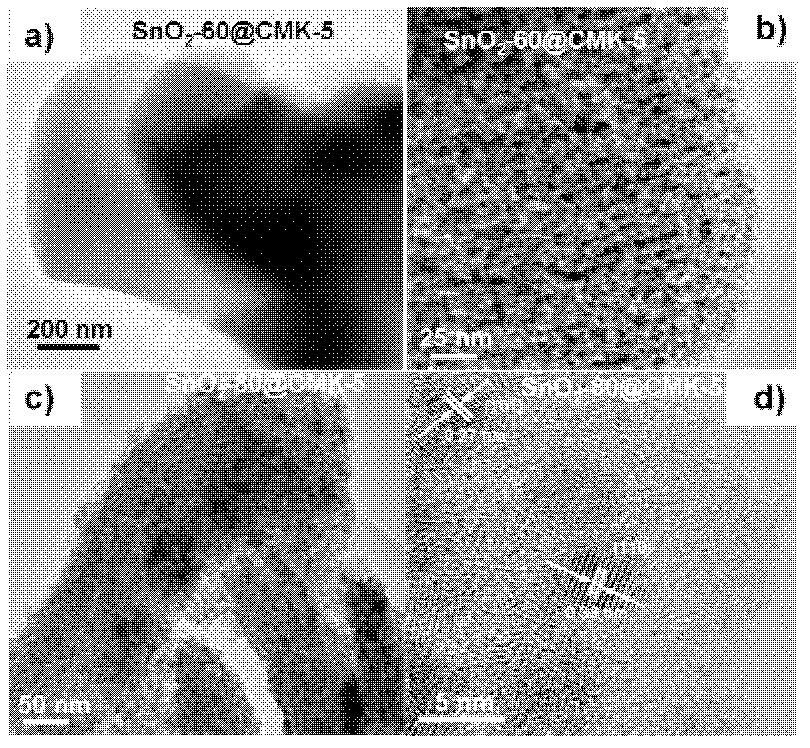

[0032] SnCl 4 ·5H 2 O (1 g, 99%) was dissolved in 1 mL of deionized water to form a solution, and then 0.6 mL of the solution was mixed with 0.2 g of CMK-5 at room temperature and mixed uniformly. After the solution is completely absorbed by CMK-5, place the black powder in a polytetrafluoroethylene bottle filled with ammonia water. The sample is not in direct contact with the ammonia water, and it is placed in a 90℃ oven for heat treatment for 3 hours to hydrolyze the tin oxide precursor in situ . Then wash with water, ethanol, and dry. To increase the load, repeat the above steps once. Finally, under the protection of Ar, the product was heated at a rate of 2°C / min to 300°C for 1 hour, and then heated to 550°C for 3 hours. Get SnO 2 SnO with a mass content of 60wt% 2 CMK-5 composite material, denoted as SnO 2 -60CMK-5.

Embodiment 2

[0034] SnCl 4 ·5H 2 O (1 g, 99%) was dissolved in 1 mL of deionized water to form a solution, and then 0.6 mL of the solution was mixed with 0.2 g of CMK-5 at room temperature and mixed uniformly. After the solution is completely absorbed by CMK-5, place the black powder in a polytetrafluoroethylene bottle filled with ammonia water. The sample is not in direct contact with the ammonia water, and it is placed in a 90℃ oven for heat treatment for 3 hours to hydrolyze the tin oxide precursor in situ . Then wash with water, ethanol, and dry. This immersion-hydrolysis step was repeated twice again. Finally, under the protection of Ar, the product was heated at a rate of 2°C / min to 300°C for 1 hour, and then heated to 550°C for 3 hours. Get SnO 2 SnO with a mass content of 80wt% 2 CMK-5 composite material.

Embodiment 3

[0036] Prepare 1.88mol / L Fe(NO 3 ) 3 ·9H 2 O (98.5%) solution, then take 0.2mL solution and 0.1g CMK-5 at room temperature and stir and mix uniformly. Then put it at 50℃ for 3h, and finally put the product at 5℃min under Ar protection -1 Heat up to 400℃ for 4h. Get γ-Fe 2 O 3 Γ-Fe with a mass content of 23wt% 2 O 3 CMK-5 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com