Compact laser chip

A compact, laser technology, applied in the laser field, which can solve the problems of low bonding yield, increased device cost, and easy formation of glue opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

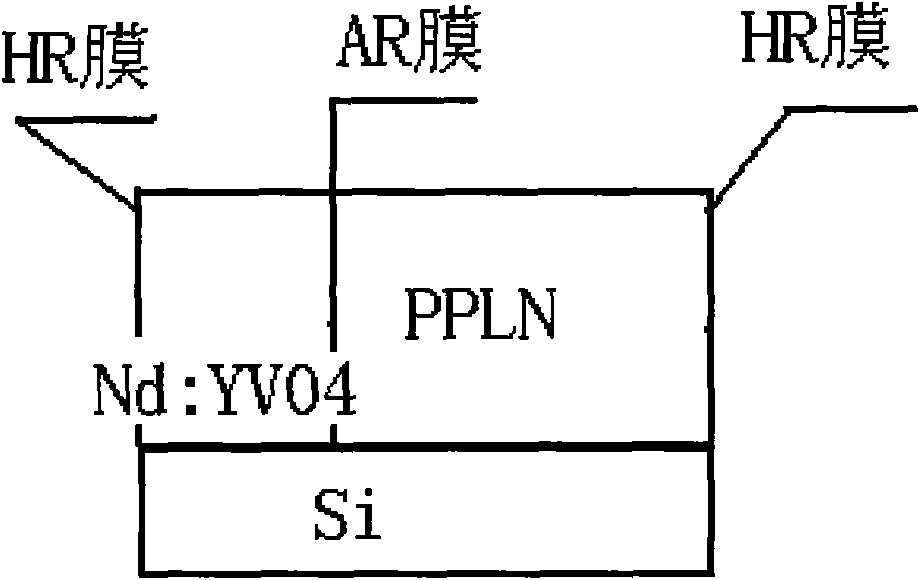

[0015] Such as Figure 5 Shown, the present invention includes 1 is the laser crystal Nd:YVO 4 , 2 is nonlinear optical crystal PPLN, 3 is heat sink and laser cavity film 4, 5, wherein the laser crystal Nd:YVO 4 Welded (or glued) the bottom surface of the nonlinear optical crystal PPLN on the heat sink to form an independent frequency doubling device, no need to make any adjustments during use, so that the frequency doubling device can achieve the purpose of long life, small size, and realize Low-cost, large-scale mass production.

[0016] The present invention can be used not only for periodically poled lithium niobate (PPLN), but also for other crystals, such as periodically poled potassium titanyl phosphate (PPKTP), periodically poled lithium tantalate (PPLT), potassium titanyl phosphate (KTP), lithium triborate (LBO), etc.; the present invention can be used not only for frequency doubling (SHG), but also for other applications, such as difference frequency (DFG), optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com