Transmission of power bidirectionally and without contact to charge electric vehicles

A vehicle, electric drive technology, used in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve problems such as increased contact resistance, easy contamination of the plug system, and danger of overheating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

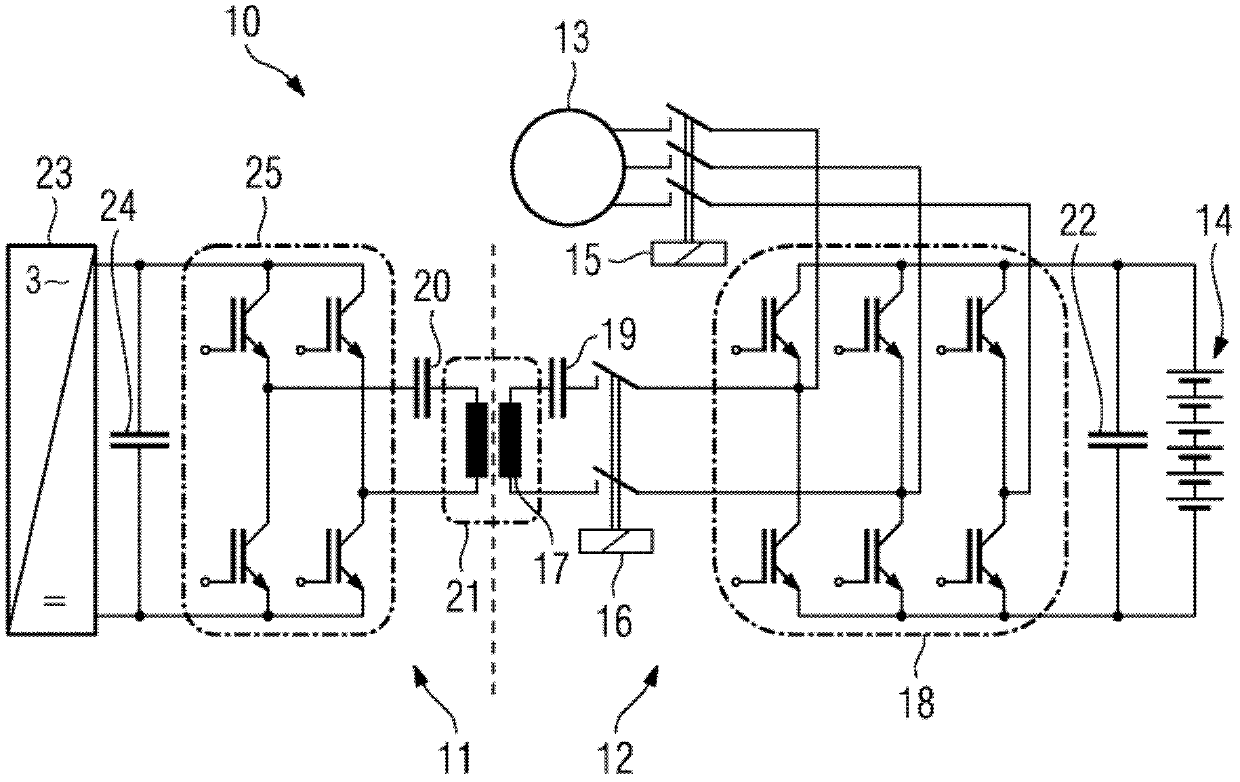

[0021] figure 1 A first overall system 10 is shown, which consists of a vehicle-side element 12 and a fixed element 11 and comprises a first embodiment of the invention. The fixed element 11 is located outside the vehicle, for example underneath the vehicle when the vehicle is at the charging station.

[0022] The vehicle-side element 12 comprises an electric motor 13 for driving the vehicle, a battery 14 , an inverter 18 , an intermediate circuit capacitor 22 , a first switching device 15 , a second switching device 16 , a coil as part of the vehicle-side of the transmitter 21 Device 17 and resonant capacitor 19 on the vehicle side.

[0023] The stationary component 11 comprises a rectifier 23 , a stationary-side intermediate circuit capacitor 24 and a stationary-side converter 25 . Furthermore, the fixed element 11 includes a fixed-side resonant capacitor 20 and a fixed-side part of a transmitter 21 .

[0024] To charge the vehicle's battery 14, the rectifier 23 converts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com