Preparation process of silver/chitosan composite antimicrobial agents

A compound antibacterial agent and preparation technology, which is applied in the direction of biocides, disinfectants, animal repellants, etc., can solve the problems of easy discoloration, restricted application of silver-based antibacterial agents, and reduced antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A preparation process of a silver / chitosan composite antibacterial agent, comprising the steps of: ① making carboxymethyl chitosan by reacting chloroacetic acid, sodium hydroxide and chitosan; ② making carboxymethyl chitosan obtained by the above reaction Sugar and silver ions are compounded to obtain a silver / chitosan composite antibacterial agent. The method introduces hydrophilic groups through carboxymethylation of chitosan, improves its water solubility on the basis of retaining the original activity of chitosan, and then combines with silver ions to obtain a composite antibacterial agent. The silver / chitosan composite antibacterial agent prepared by the preparation process can not only solve the problem of easy discoloration of silver antibacterial agents, but also greatly improve the antibacterial properties of chitosan.

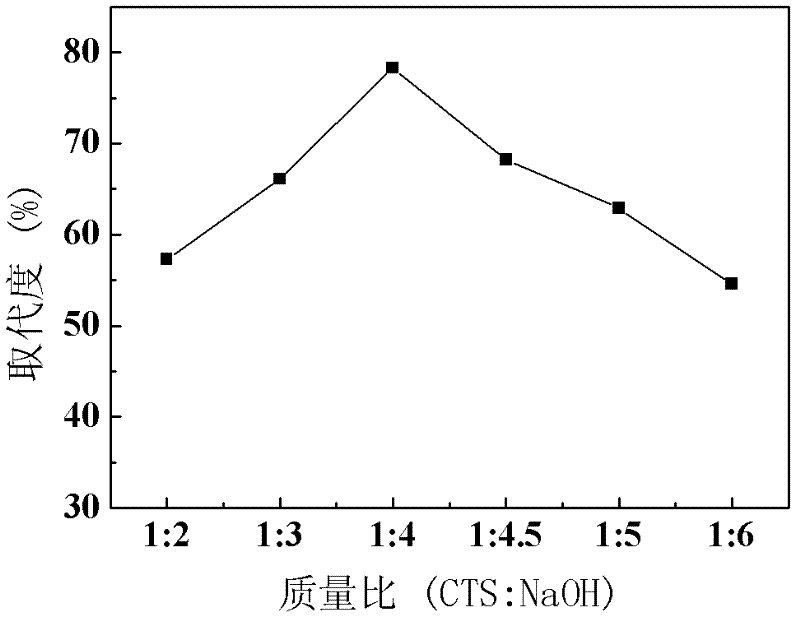

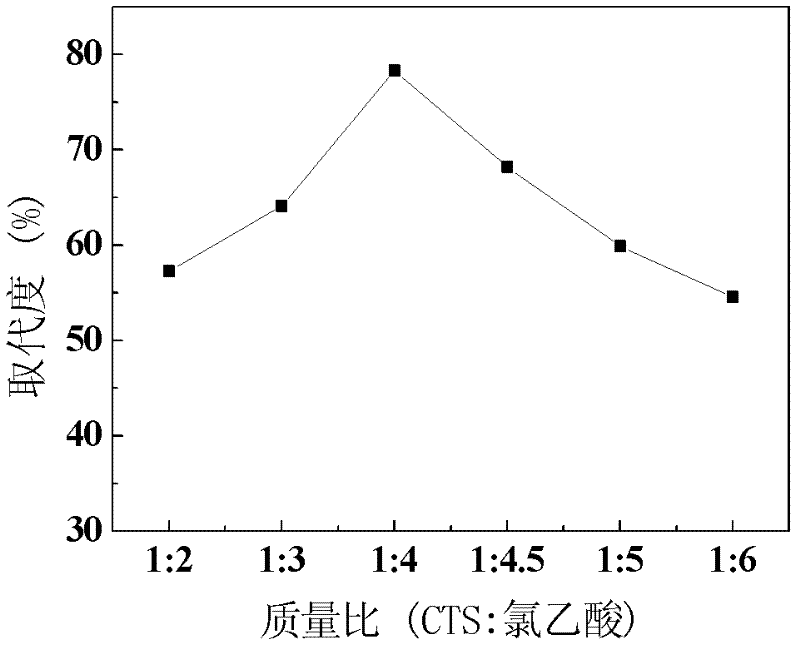

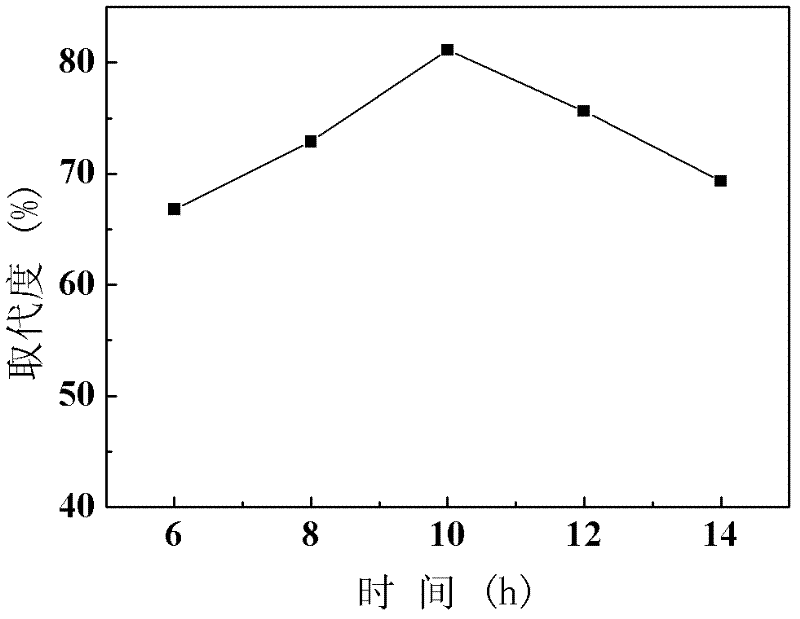

[0014] In the step ①, the mass ratio of chitosan to NaOH and chloroacetic acid is 1:2-4:2-4, the reaction temperature is 30-70° C., and the re...

Embodiment 1

[0029] ①Carboxymethyl chitosan was prepared by reacting chloroacetic acid, sodium hydroxide and chitosan, the mass ratio of chitosan to NaOH and chloroacetic acid was 1:2:2, the reaction temperature was 30°C, and the reaction time was 6h .

[0030] ② Then silver nitrate and ethylenediaminetetraacetic acid are complexed in an equimolar ratio, and stirred and reacted at normal temperature and pressure for 10 to 30 minutes. Then the carboxymethyl chitosan of above-mentioned reaction gained is compounded with the silver nitrate after complexation, finally obtains silver / chitosan composite antibacterial agent, the reaction mass ratio of carboxymethyl chitosan and silver nitrate is controlled at 1: 0.01.

Embodiment 2

[0032] ①Carboxymethyl chitosan is produced by the reaction of chloroacetic acid, sodium hydroxide and chitosan, the mass ratio of chitosan to NaOH and chloroacetic acid is 1:3:3, the reaction temperature is 60°C, and the reaction time is 10h .

[0033] ② Then silver nitrate and ethylenediaminetetraacetic acid are complexed in an equimolar ratio, and stirred and reacted at normal temperature and pressure for 10 to 30 minutes. Then the carboxymethyl chitosan of above-mentioned reaction gained is compounded with the silver nitrate after complexation, finally obtains silver / chitosan composite antibacterial agent, the reaction mass ratio of carboxymethyl chitosan and silver nitrate is controlled at 1: 0.03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com