Complex gum as well as low-acidity jelly prepared from same and preparation method thereof

A technology of low-acidity, compound glue, applied in food preparation, application, food science, etc., can solve the problems of undeveloped low-acidity jelly products, improve diversity and innovation, uniform texture, and avoid the use of preservatives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

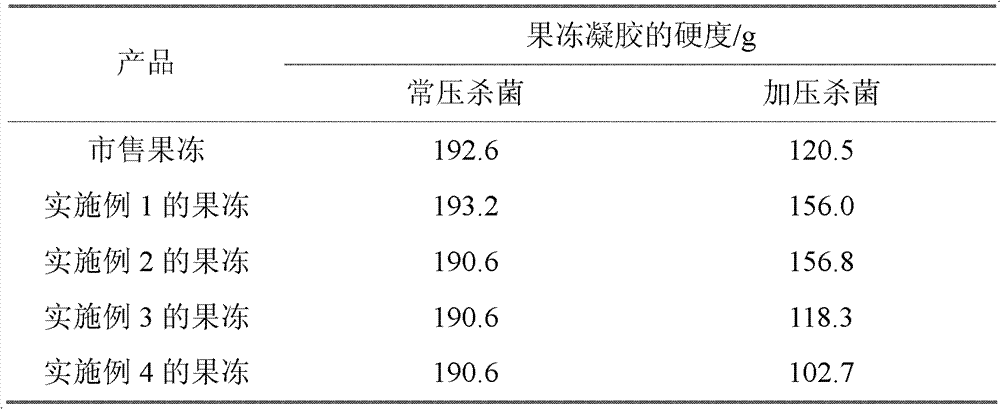

Embodiment 1

[0021] (1) Preparation of compound gum: konjac gum 1.47kg, carrageenan 2.17kg, xanthan gum 2.59kg, locust bean gum 0.77kg, potassium chloride 0.543kg, dry mix the above substances evenly.

[0022] (2) Preparation of rice and soybean slurry: after soaking 3 kg of soybeans overnight, add 36 kg of water for beating, pass through 140-mesh gauze to remove slag, and then pass through a 140-mesh sieve to obtain soybean slurry. Add 10kg of rice flour to the soybean slurry, fully stir to form the rice soybean slurry.

[0023] (3) After dry-mixing 7.543kg of compound glue and 140kg of white granulated sugar evenly, add 700kg of water and stir while adding to make it fully dissolve. Then add the above-mentioned rice and soybean slurry, stir evenly, and add water to a total amount of 1000kg.

[0024] (4) After homogenizing the above-prepared glue to refine the particles, let the system fully absorb water and swell for 1 hour. Then the mixture was heated in a water bath at 90° C. for 15 ...

Embodiment 2

[0030] (1) Preparation of compound gum: konjac gum 1.47kg, carrageenan 2.17kg, xanthan gum 2.59kg, locust bean gum 0.77kg, potassium chloride 0.543kg, dry mix the above substances evenly.

[0031] (2) Dry mix 7.543kg of compound glue, 140kg of white granulated sugar, and 30kg of skimmed milk powder evenly, then add 700kg of water, stir while adding to make it fully dissolve, and add water to a total of 1000kg.

[0032] (3) After homogenizing the above-prepared glue to refine the particles, let the system fully absorb water and swell for 1 hour. Then the mixture was heated in a water bath at 85° C. for 15 min, and stirred while heating to make it fully sol.

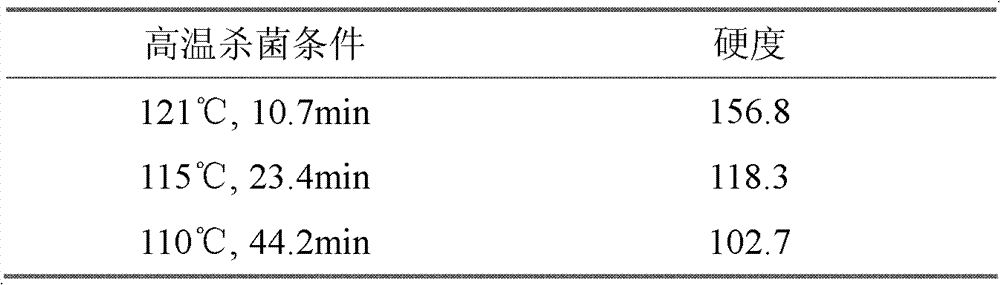

[0033] (4) After the glue solution after the sol is hot filled and sealed, carry out high temperature back pressure sterilization. The sterilization conditions are: temperature 121°C, back pressure 1.55bar, bactericidal effect F value 3.6min.

Embodiment 3

[0035] (1) Preparation of compound gum: konjac gum 1.47kg, carrageenan 2.17kg, xanthan gum 2.59kg, locust bean gum 0.77kg, potassium chloride 0.543kg, dry mix the above substances evenly.

[0036] (2) Dry mix 7.543kg of compound glue, 140kg of white granulated sugar, and 30kg of skimmed milk powder evenly, then add 700kg of water, stir while adding to make it fully dissolve, and add water to a total of 1000kg.

[0037] (3) After homogenizing the above-prepared glue to refine the particles, let the system fully absorb water and swell for 1 hour. Then the mixture was heated in a water bath at 85° C. for 15 min, and stirred while heating to make it fully sol.

[0038] (4) After the glue solution after the sol is hot filled and sealed, carry out high temperature back pressure sterilization. The sterilization conditions are: temperature 115°C, back pressure 1.30bar, bactericidal effect F value 3.6min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com