Process for producing potassium N-methyldithiocarbamate

A technology of methyl dithioamino and potassium formate, which is applied in biocides, chemicals for biological control, nematocides, etc., can solve the problems of low agricultural mechanization and achieve sustainable use, Good effect, saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

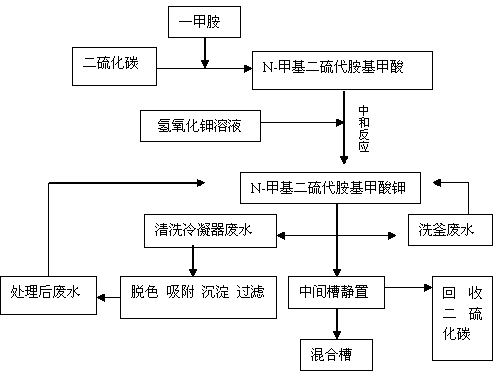

[0018] combined with figure 1 To specifically illustrate the production process of the present invention.

[0019] First, 40%wt monomethylamine aqueous solution containing 0.95 mole of monomethylamine was gradually added dropwise into 1.05 mole of carbon disulfide and reacted at 15~45°C for 2~3h to obtain N-methyldithiocarbamic acid. Since this reaction is an exothermic reaction, it is necessary to increase cooling and control the rate of addition during the reaction to ensure that the reaction temperature does not exceed 45°C.

[0020] Then, add 30%wt potassium hydroxide aqueous solution containing 1.0 moles of potassium hydroxide and carry out neutralization reaction at 35~45°C for 3h to obtain N-methyldithiocarbamic acid potassium solution to obtain N-methyldithiocarbamate The mass percent concentration of the potassium carbamate solution was 52.3%, and the yield was 98.0%. Then, after putting the reaction solution into the middle tank of the cone and standing for stratif...

Embodiment 2

[0024] combined with figure 1 To specifically illustrate the production process of the present invention.

[0025] First, 40%wt monomethylamine aqueous solution containing 0.97 mole of monomethylamine was gradually added dropwise into 1.1 mole of carbon disulfide and reacted at 15~45°C for 2~3h to obtain N-methyldithiocarbamic acid. Since this reaction is an exothermic reaction, it is necessary to increase cooling to control the rate of addition during the reaction, so as to ensure that the reaction temperature does not exceed 45°C.

[0026] Then, add 30% potassium hydroxide aqueous solution containing 1.02 moles of potassium hydroxide and carry out neutralization reaction at 35~45°C for 2 hours to obtain N-methyldithiocarbamic acid potassium solution to obtain N-methyldithioamine The mass percentage concentration of potassium formate solution is 55.6%, yield 98.3%

[0027] Then, after putting the reaction solution into the middle tank of the cone and standing for stratifica...

Embodiment 3

[0031] combined with figure 1 To specifically illustrate the production process of the present invention.

[0032] First, 40%wt monomethylamine aqueous solution containing 0.99 mole of monomethylamine was gradually added dropwise into 1.2 mole of carbon disulfide and reacted at 15~45°C for 2~3h to obtain N-methyldithiocarbamic acid. Since this reaction is an exothermic reaction, it is necessary to increase cooling to control the rate of addition during the reaction, so as to ensure that the reaction temperature does not exceed 45°C.

[0033] Then, add 30% potassium hydroxide aqueous solution containing 1.05 moles of potassium hydroxide and carry out neutralization reaction at 35~45°C for 2 hours to obtain N-methyldithiocarbamic acid potassium solution to obtain N-methyldithioamine The mass percentage concentration of potassium methionate solution is 60%, yield 98.9%

[0034] Then, after putting the reaction solution into the middle tank of the cone and standing for stratific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com