Method and decomposition stove for preparing lime in suspended state with wood coal as fuel

A decomposition furnace, part of the technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of low production efficiency, unfavorable for bituminous coal combustion, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

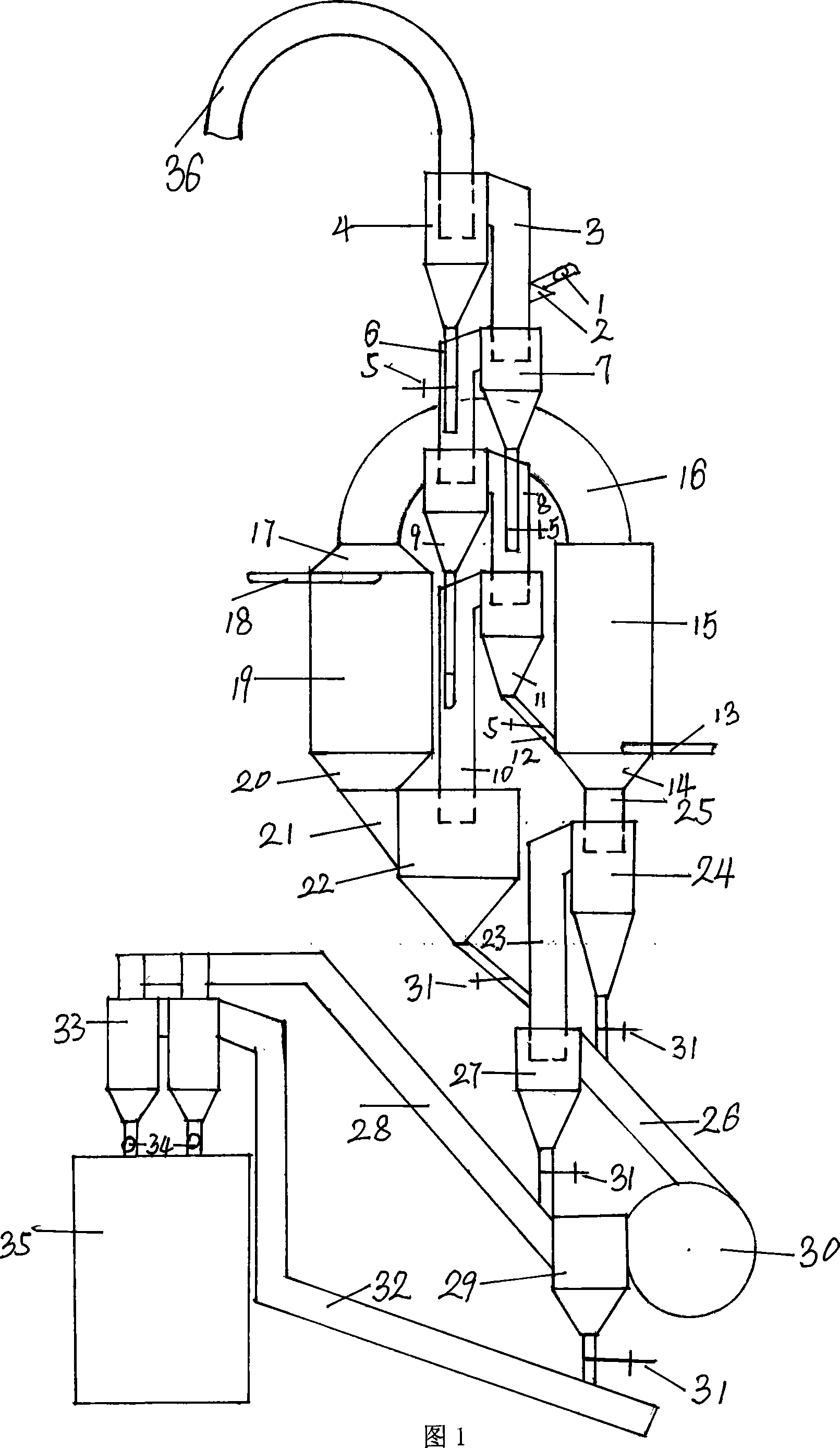

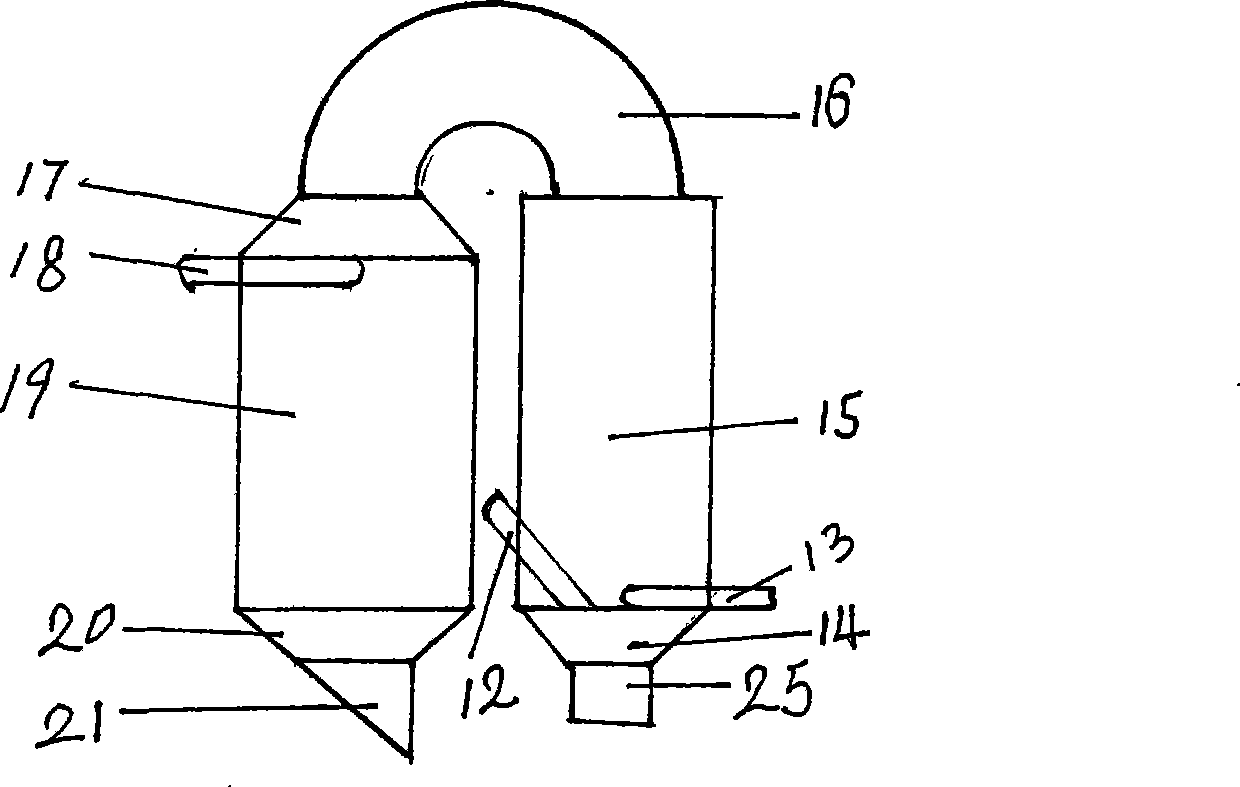

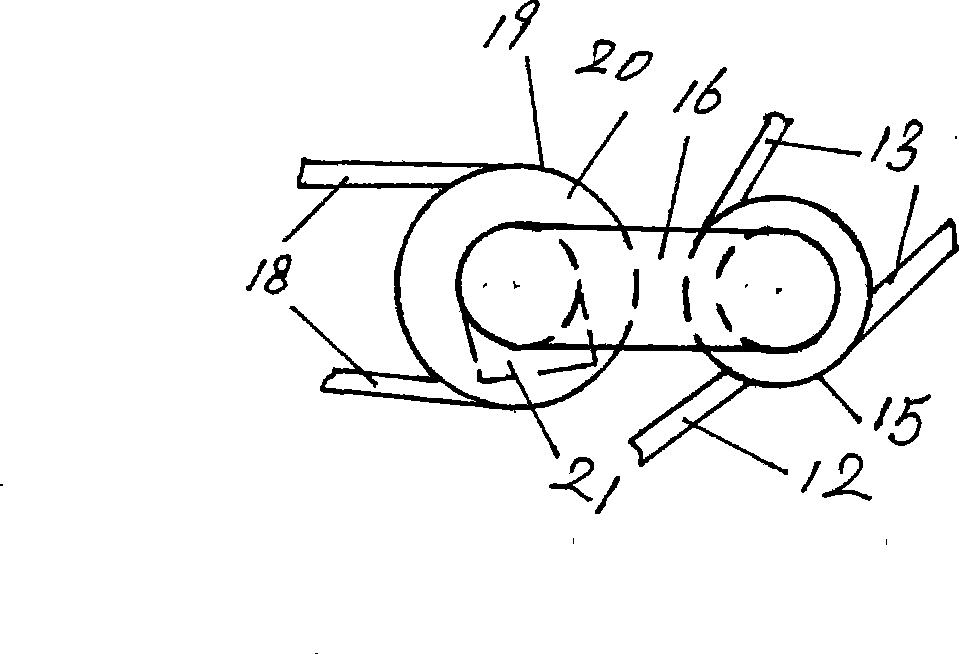

[0010] Limestone powder is fed from C2 to C1 ascending pipeline 3 by star feeder 1, mixed with the hot air from cyclone dust collector 7 and enters cyclone dust collector 4 together; after gas-solid separation, the gas is sent to waste heat by pipeline 36 After the power generation and heat supply system, part of it is discharged into the atmosphere after being treated by the waste gas treatment system; the other part is discharged into the atmosphere after dust collection treatment by the lignite drying and grinding system. The solid enters the ascending pipe 6 from C3 to C2, and then passes through the cyclone dust collector 7, the ascending pipe 8 from C4 to C3, the cyclone dust collector 9, the ascending pipe 10 from C5 to C4, and the cyclone dust collector 11 and is heated to about 700°C. After that, it is fed into the calciner by the feed pipe 12; about 70% of the coal powder is sprayed into the end column 15 by the powder nozzle 13; the high-temperature gas after cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com