Crosslinked polyvinyl chloride foam and preparation method thereof

A technology of cross-linked polyvinyl chloride and polyvinyl chloride, which is applied in the field of foam materials, can solve problems such as cumbersome operation, and achieve the effects of improving thermal stability and toughness, good dimensional stability and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention also provides a kind of preparation method of cross-linked polyvinyl chloride foam, comprises the following steps:

[0073] Foaming and molding a polyvinyl chloride mixture, the polyvinyl chloride mixture comprising:

[0074] The polyvinyl chloride resin of 100 weight parts;

[0075] 30-150 parts by weight of isocyanate;

[0076] 1~15 parts by weight of foaming agent;

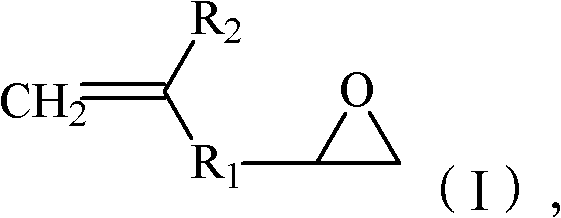

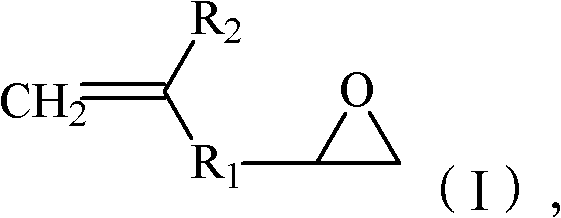

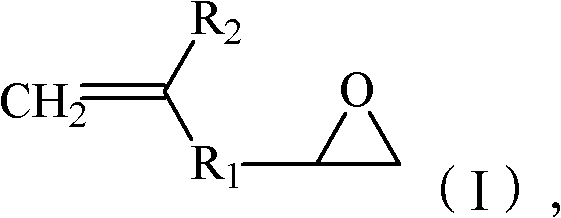

[0077] 1 to 30 parts by weight of a compound of formula (I):

[0078]

[0079] Among them, R 1 is a hydrocarbon group, a substituted hydrocarbon group, an ester group, a carbonyl group, an ether group or an amide group, R 2 is H, aliphatic, phenyl, nitro, cyano or halogen;

[0080] The foamed molded product is subjected to secondary foaming and curing in water or water vapor to obtain cross-linked polyvinyl chloride foam.

[0081] The present invention uses a polyvinyl chloride mixture comprising polyvinyl chloride resin, isocyanate, blowing agent and a compound having the ...

Embodiment 1

[0100] Mix 600g of PVC resin, 120g of GMA, 600g of liquefied MDI and 60g of AIBN evenly, add them into the mold, perform foaming and molding at a temperature of 175°C and a pressure of 16MPa, cool to 40°C and open the mold, and place the foamed molded product at 85 ℃ hot water for secondary foaming, and then placed in 65 ℃ water vapor for curing and setting to obtain cross-linked PVC foam, its performance is shown in Table 1, Table 1 is the performance of the cross-linked PVC foam prepared in Examples 1-10 surface.

Embodiment 2

[0102] Mix 600g of PVC resin, 180g of GA, 180g of TDI, 30g of styrene, 30g of vinylpyridine, 60g of AIBN and 30g of AC, and add them into the mold, foam and press at a temperature of 171°C and a pressure of 15MPa, cool to 20°C and open the mold. The foamed molded product obtained was placed in 95°C water vapor for secondary foaming, and then placed in 55°C hot water for curing and setting to obtain a cross-linked PVC foam, whose properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com