Novel over-speed bright quenching oil composition and preparation method thereof

A quenching oil and composition technology, applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems affecting the heat treatment quality of parts, low moisture content, accidents, etc., and achieve excellent bright performance, fast cooling speed, and easy obtained effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

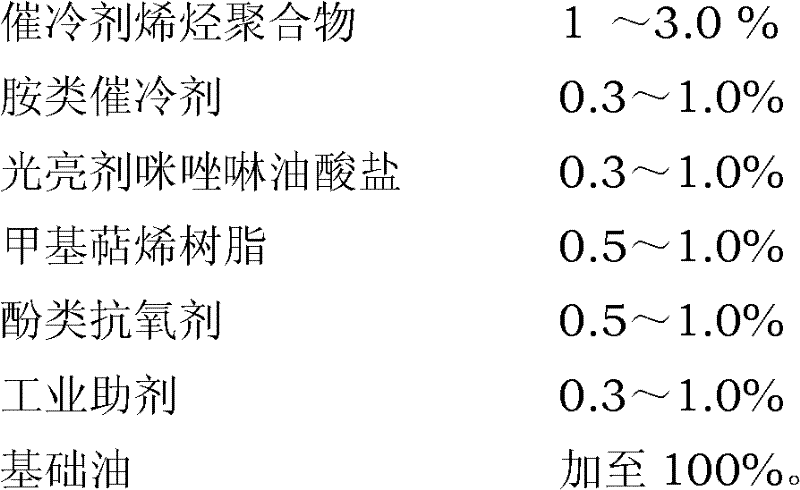

[0020] A new ultra-fast bright quenching oil composition, the components are shown in the following table:

[0021] name

Mass %

150SN base oil

100

polyisobutylene

3

0.3

imidazoline oleate

1.0

methyl terpene resin

1.0

T501 antioxidant

0.5

Siben 80

0.3

[0022] Preparation

[0023] 1. Put formamide, Siben 80, imidazoline oleate and polyisobutylene into a mixing tank.

[0024] 2. Add methyl terpene resin and T501 antioxidant to 5 parts of 150SN base oil, heat and stir until completely dissolved, then pour into the mixing tank.

[0025] 3. Put the remaining 95 parts of 50SN base oil into the stirring tank, and stir thoroughly. If the room temperature is too low, heat it properly.

[0026] The excellent characteristics of the novel ultra-fast bright quenching oil composition prepared by the present invention are as follows:

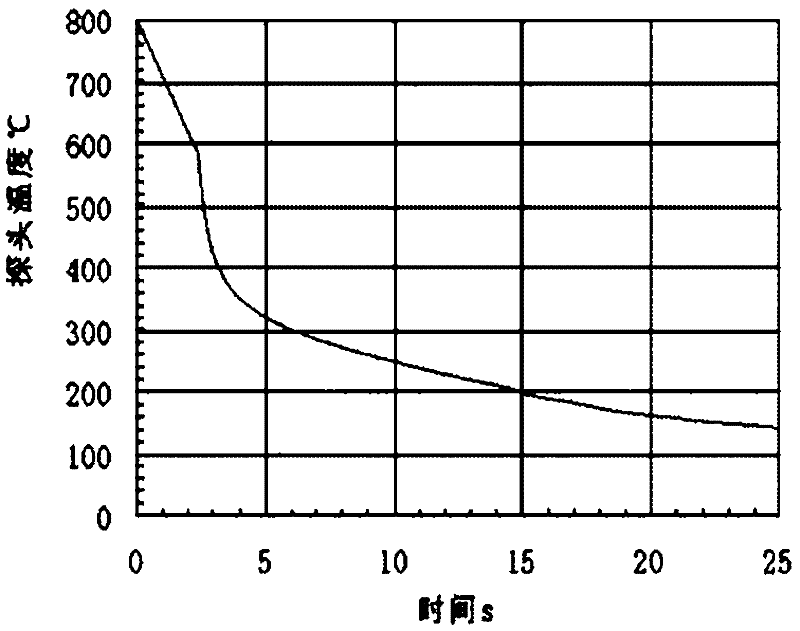

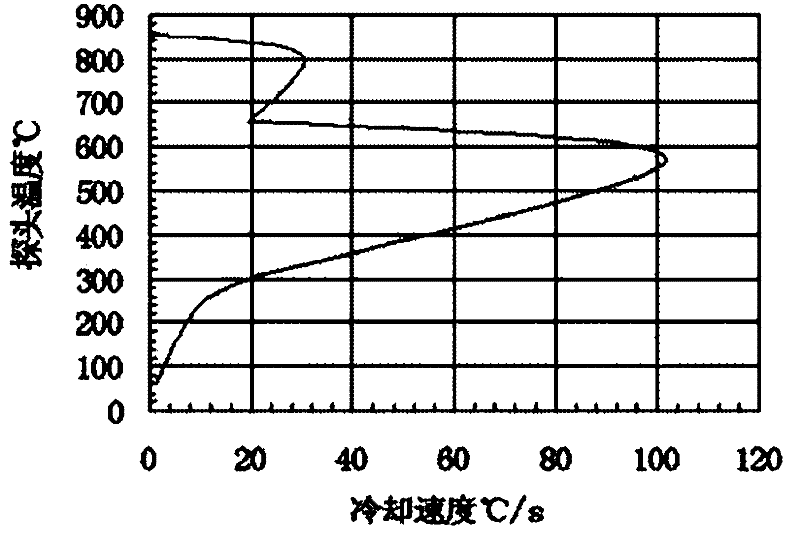

[0027] Ultra-speed bright quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com