Surface acoustic wave pressure sensor based on multiple couplers

A pressure sensor and surface acoustic wave technology, which is used in the measurement of fluid pressure using piezoelectric devices, and the measurement of property forces using piezoelectric devices, to achieve the effects of high precision, good structural manufacturability, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

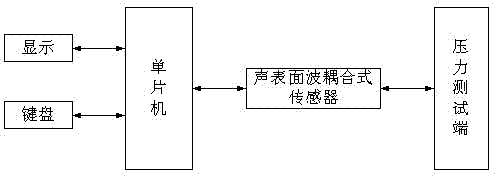

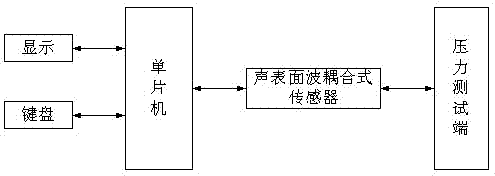

[0015] like figure 1 As shown, the present invention provides a multi-coupler-based surface acoustic wave pressure sensor, including a coupler type surface acoustic wave pressure sensor, the input end of the coupler type surface acoustic wave pressure sensor is connected to the pressure test end, and its output end is connected to The single-chip microcomputer is connected in a bus mode, and a display module and a key module are connected to the single-chip microcomputer.

[0016] The single-chip microcomputer in this system adopts AT89C51, which is a low-power, high-performance CMOS 8-bit microcontroller with 8K in-system programmable Flash memory and does not require external expansion memory, which makes the structure of the whole system simple. The display module adopts 1602LCD display. The button module has a total of three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com