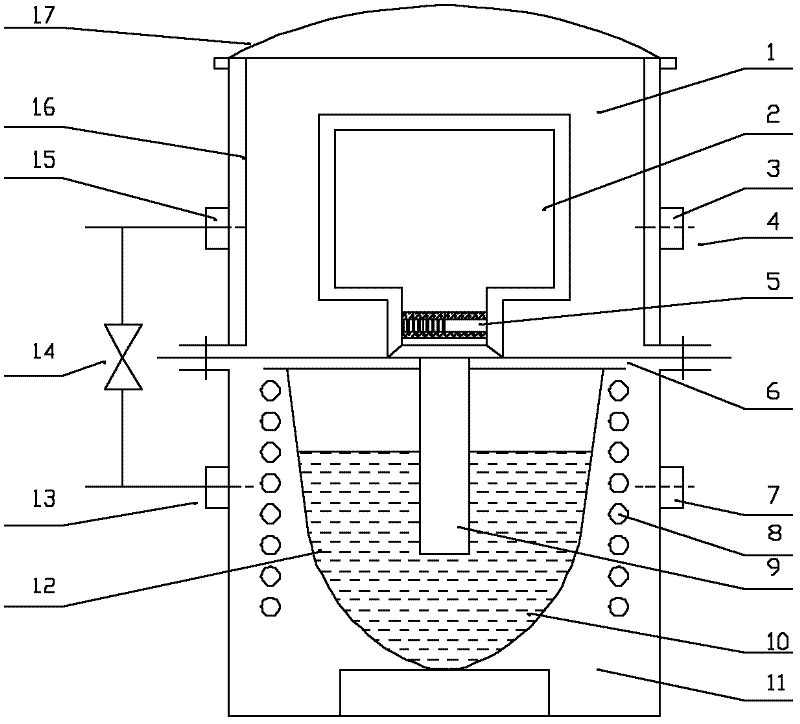

Casting device of low tension fine grain and method thereof

A fine-grained, low-pressure technology, applied in the field of foundry metallurgy, can solve the problems that large-scale casting methods are not suitable and cannot be used in pressure-regulated casting methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-4

[0034] Based on the device described in Example 1, for the K4169 superalloy melt, the filling rate is controlled to vary from 0.1 to 1 m / s, and the melt temperature is adjusted by the power of the melting device and a thermocouple, and is appropriately changed with the change of the filling rate.

[0035] The low-pressure fine-grain casting method includes the following steps:

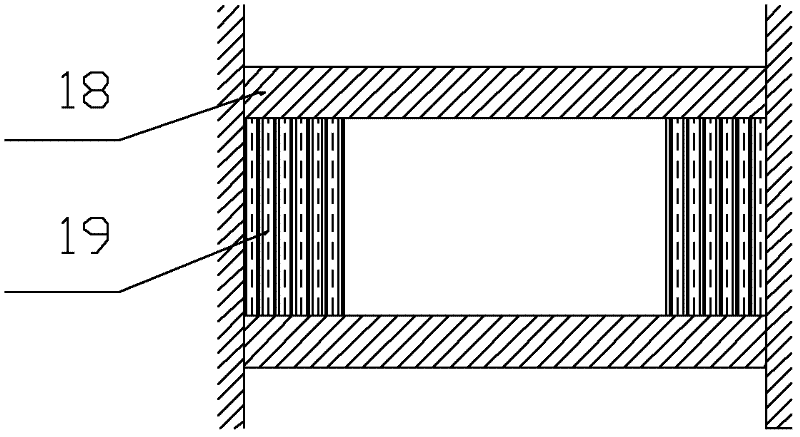

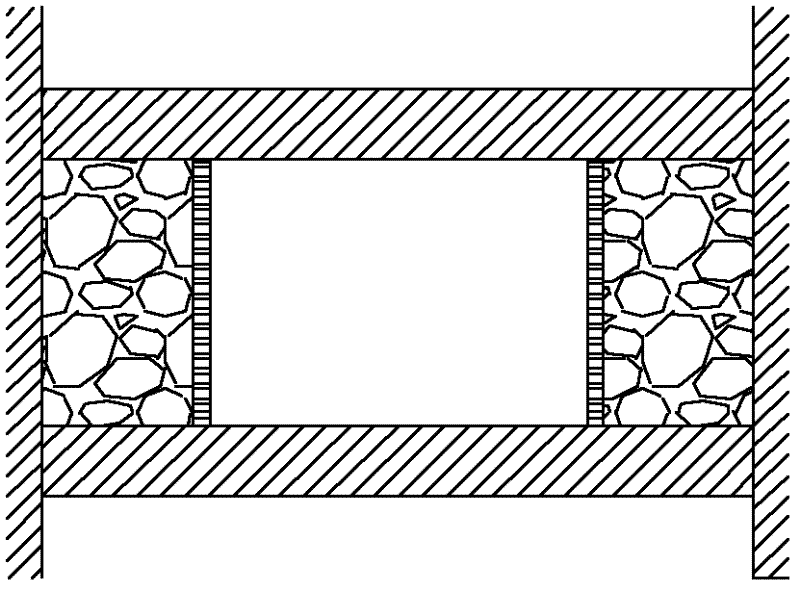

[0036] Step 1: put the refiner into the refiner storage, and connect the sprue mouth pipe;

[0037] Step 2: Then pour aluminum melt or superalloy melt into the crucible, and turn on the pressure regulating casting device;

[0038] Step 3: During the mold filling process, the gas filling rate is adjusted by the air pressure regulating device to control the filling rate so that the superalloy melt rises from the crucible along the riser at a set rate; when the melt flows through the refiner storage At this time, due to the momentum and temperature of the fluid, the refiner will be mixed, melted, and bro...

Embodiment 2

[0040] Example 2: When the filling speed is 0.1m / s, when the casting is solidified under the pressure of 0.6Mpa, the shrinkage porosity ratio in the casting is 3%, and when the melt temperature is 1400°C, the superalloy grain size is 8mm.

Embodiment 3

[0041] Example 3: When the filling rate is 0.5m / s, the melt temperature is 1390°C, and the casting is solidified under a pressure of 0.6Mpa, when the shrinkage-porosity ratio in the casting is 3%, the superalloy grain size is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com