Synthesis method of cystamine dihydrochloride

A technology of cystamine dihydrochloride and cystamine dihydrochloride, which is applied in the field of solid-phase synthesis of cystamine dihydrochloride at room temperature, can solve the problems of high production cost and complicated production process, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 864g of composite glue, 1620g of water, 4320g of cysteamine hydrochloride, 2376g of 120 mesh powdered silicon dioxide and 1620g of aminobutyric acid, add the composite glue to water, add cysteamine hydrochloride, stir evenly, and place at room temperature 2h, grind twice with a colloid mill, add silica to absorb into solid powder, finally add aminobutyric acid and stir for 10min, place in the container at room temperature of 25°C for 62h, the internal temperature of the material is consistent with the ambient temperature, and the reaction is completed. The reaction product was dissolved in water and filtered, and the filtrate was purified with ethanol to obtain pure cystamine dihydrochloride. The composition of the composite glue is 258g of carboxymethyl cellulose, 172g of sodium alginate and 430g of xanthan gum.

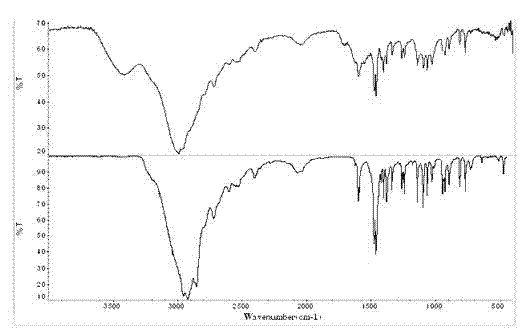

[0019] The infrared spectrogram of cystamine dihydrochloride prepared after the purification of the reaction product of this embodiment is as follows ...

Embodiment 2

[0021] Weigh 860g of composite glue, 2150g of water, 1720g of cysteamine hydrochloride, 3010g of 80 mesh powdered silicon dioxide and 860g of aminobutyric acid, add the composite glue to water, add cysteamine hydrochloride, stir evenly, and place at room temperature 3h, grind twice with a colloid mill, add silica to absorb into solid powder, finally add aminobutyric acid and stir for 10min, place in a container at room temperature of 35°C for 48h, the internal temperature of the material is consistent with the ambient temperature, and the reaction is completed. The reaction product was dissolved in water and filtered, and the filtrate was purified with ethanol to obtain pure cystamine dihydrochloride. The composition of the composite gum is 345.6 g of carboxymethyl cellulose, 259.2 g of sodium alginate and 259.2 g of xanthan gum.

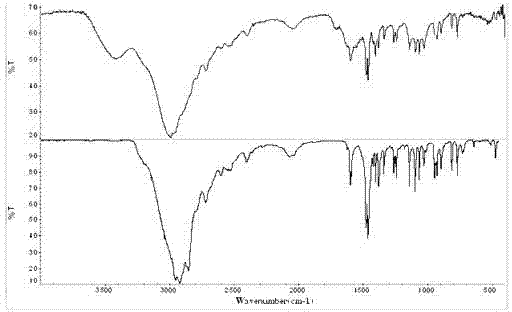

[0022] After the reaction product was purified, it was identified as cystamine dihydrochloride by infrared spectrum analysis, and the reduction and...

Embodiment 3

[0024] Weigh 59.5g of composite glue, 1190g of water, 2975g of cysteamine hydrochloride, 1666g of 150 mesh powdered silicon dioxide and 59.5g of aminobutyric acid, add the composite glue to water, add cysteamine hydrochloride, stir evenly, Place at room temperature for 3 hours, grind once with a colloid mill, add silica to absorb into solid powder, and finally add aminobutyric acid and stir for 10 minutes, place in a container at room temperature at 15°C for 120 hours, and the internal temperature of the material is consistent with the ambient temperature, and the reaction is completed. The reaction product was dissolved in water and filtered, and the filtrate was purified with ethanol to obtain pure cystamine dihydrochloride. The composition of the composite gum is 29.75 g of carboxymethyl cellulose, 5.95 g of sodium alginate and 23.8 g of xanthan gum.

[0025] After purification, the reaction product was identified as cystamine dihydrochloride by infrared spectrum analysis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com