Double-shaft fluxgate current sensor

A technology of current sensor and current transformer, which is applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of long response time, low sensitivity, weak signal, etc., and achieve the suppression of the influence of measurement work and wear resistance Excellent performance and corrosion resistance, and the effect of suppressing input signal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

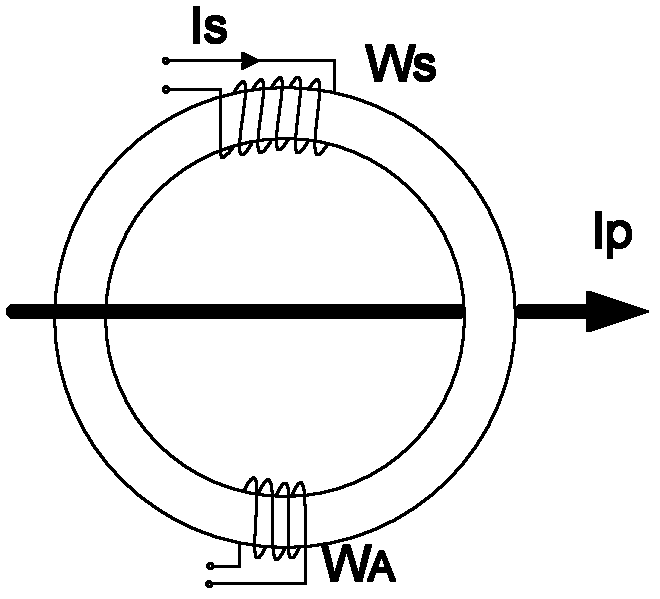

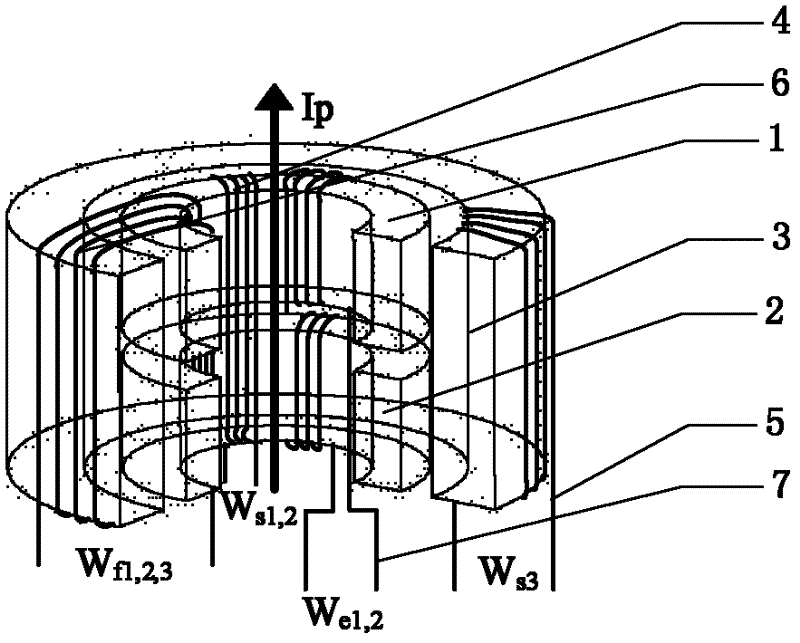

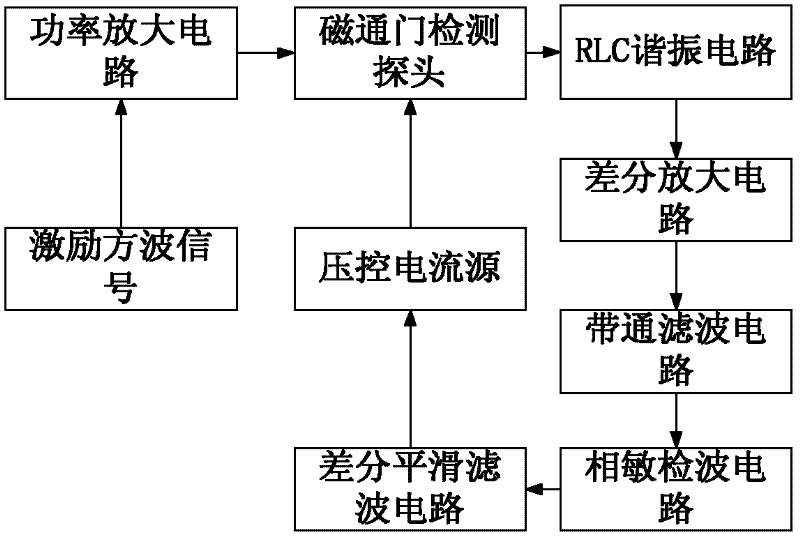

[0058] as above figure 2 The embodiment shown in the device is a fluxgate detection probe of a biaxial fluxgate current sensor and a zero-flux current transformer, wherein the fluxgate detection probe is composed of an inner annular magnetic core a1 and an inner annular magnetic core b2 arranged side by side , excitation winding W e1,2 7 is a wire wound on the inner ring magnetic core a1 for 100 turns to form the excitation winding W e1,2 7W e1 part, and then wind 100 turns on the inner ring core b2 in the opposite direction to form the excitation winding W e1,2 7W e2 part, the induction winding W s1,2 4 Wind the two inner ring cores a1 and b2 placed side by side together for 70 turns, in which the induction winding W on the inner ring core a1 s1,2 4 parts called W s1 , the induction winding W on the inner ring core b2 s1,2 4 parts called W s2 ; The zero-flux current transformer consists of an outer ring core 3 and a secondary side winding W S3 5 composition, the se...

Embodiment 2

[0062] In addition to excitation winding W e1,2 7 is a wire wound on the inner ring magnetic core a1 for 100 turns to form the excitation winding W e1, 2 7W e1 part, and then wind 100 turns on the inner ring core b2 in the opposite direction to form the excitation winding W e1,2 7W e2 part, the induction winding W s1,2 4 Wind the two inner ring cores a1 and b2 placed side by side together for 70 turns, in which the induction winding W on the inner ring core a1 s1,2 4 parts called W s1 , the induction winding W on the inner ring core b2 s1,2 4 parts called W s2 Except, other is with embodiment 1.

[0063] The above-mentioned biaxial fluxgate current sensor is used for the measurement experiment of low-frequency alternating current. The measurement method and process are the same as in Embodiment 1. The measured current is from -30A to 30A, and the voltage on the sampling resistor 17 is measured.

Embodiment 3

[0065] In addition to excitation winding W e1,2 7 is a wire wound on the inner ring magnetic core a1 for 100 turns to form the excitation winding W e1, 2 7W e1 part, and then wind 100 turns on the inner ring core b2 in the opposite direction to form the excitation winding W e1,2 7W e2 part, the induction winding W s1,2 4 Wind the two inner ring cores a1 and b2 placed side by side together for 70 turns, in which the induction winding W on the inner ring core a1 s1,2 4 parts called W s1 , the induction winding W on the inner ring core b2 s1,2 4 parts called W s2 Except, other is with embodiment 1.

[0066] The above-mentioned biaxial fluxgate current sensor is used for the measurement experiment of high-frequency alternating current. The measurement method and process are the same as those in Embodiment 1. The frequency of the measured current can reach up to 20KHz, and the voltage on the sampling resistor 17 is measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation flux density | aaaaa | aaaaa |

| Saturation flux density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com