Fluorescent lamp

A fluorescent lamp and phosphor technology, applied in the field of fluorescent lamps, can solve the problems of maintaining illuminance, degradation, and difficulty in maintaining stability for a long time, and achieve the effects of extending service life, increasing light output, and high light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

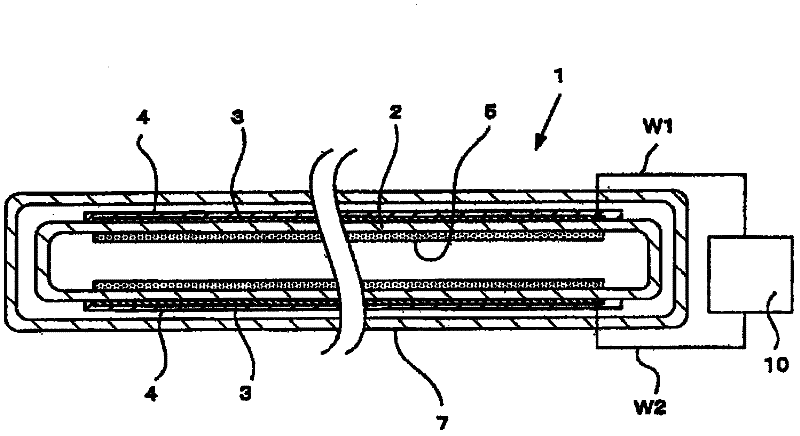

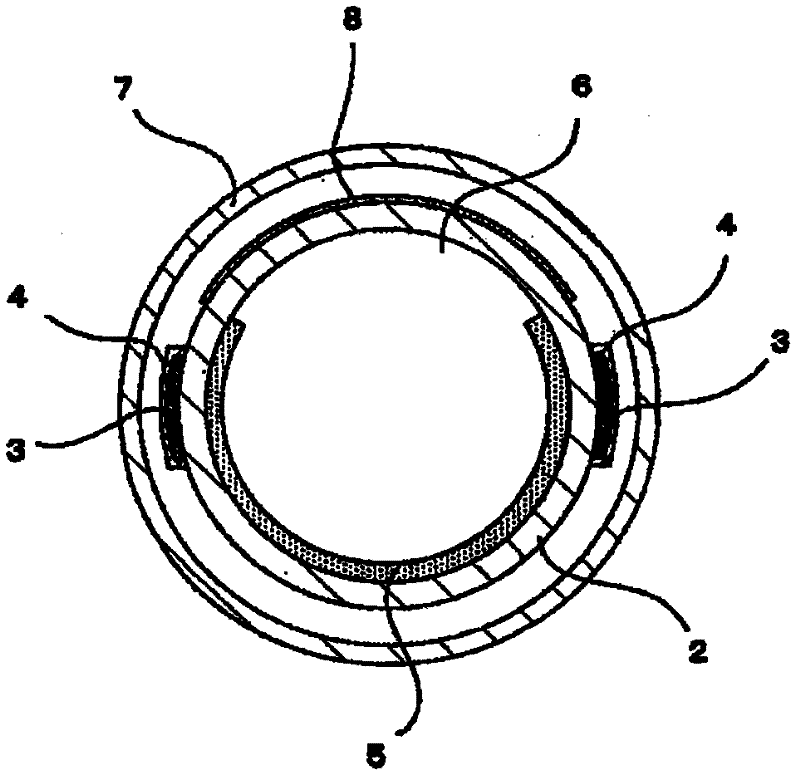

[0022] figure 1 It is a sectional view of the fluorescent lamp of this invention.

[0023] In this figure, a fluorescent lamp 1 is provided with a pair of external electrodes 3 and 3 facing each other on the outer peripheral surface of a light emitting tube 2 . The external electrodes 3, 3 have a substantially band-like shape extending in the direction of the tube axis, and pass through a conductive film such as a silver paste mixed with silver (Ag) and fritted glass, or a gold paste mixed with gold (Au) and fritted glass. form.

[0024] The external electrodes 3, 3 are covered with protective films 4, 4 made of glass layers, and the external electrodes 3, 3 are respectively connected with wires W1, W2, which are connected to a power source 10 for generating a high-frequency voltage.

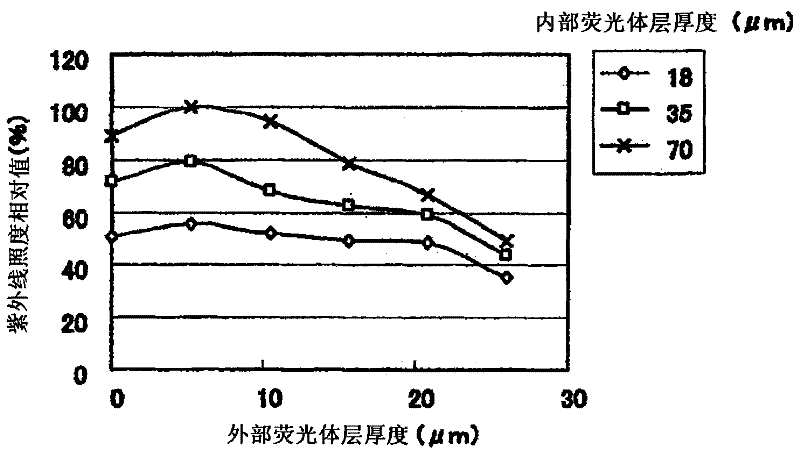

[0025] The luminous tube 2 is made of synthetic quartz glass having high transmittance to vacuum ultraviolet light with a wavelength of 200 nm or less. Furthermore, in order to improve the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com