Method for producing fully expanded whole-grain corn

A technology of puffed corn and processing method, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of troublesome process, poor safety and bad appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Peeling of corn Dry the harvested raw waxy corn germ to a water content of less than 10%, then soak it in an alkaline solution, remove the draining liquid for 1 minute, rinse and drain, and then put the corn into a peeling machine to remove After peeling, the corn is rinsed with water and soaked overnight in an acidic solution; wherein, the concentration of the lye is 2% to 9%, and the pH of the acidic solution is 2 to 5.

[0023] (2) After the corn is boiled and dried, the corn is soaked, taken out, put into boiling water and boiled for 1-2 hours, rinsed with clean water for 20 seconds after being taken out, and spread on the stainless steel mesh shelf with a thickness of 1-3 cm. Put it in a cold storage at 2-4°C for 24-72 hours to age, dry it at a constant temperature of 60°C until the water content is about 15%, then pack it in a woven bag, put it in a cold storage at 2-4°C for 5-15 days and age it again for later use.

[0024] (3) Frying, breading, and packaging...

Embodiment 2

[0029] The difference from Example 1 is that the temperature of the alkali solution in the step (1) is 80° C., the concentration is 2%, and the soaking time is 20 minutes; the pH of the acidic solution is 2, the temperature is 60° C., and the soaking time is 12 hours.

[0030] Cook in the step (2) for 1 hour and then take it out and wash it with clear water. The thickness of the corn covered by the stainless steel mesh layer frame is 1 cm. The first aging time is 24 hours, the constant temperature drying temperature is 50°C, the moisture content of the corn after constant temperature drying is 14%, and the second aging time is 15 days.

[0031] The frying time in the step (3) is 6 minutes, the oil temperature is controlled at 180° C., immersed in cold coconut oil for 3 minutes, removed and drained for 5 minutes, and coated with flour when the temperature drops to 70° C.

Embodiment 3

[0033] The difference from Example 1 is that in the step (1), the temperature of the alkali solution is 40° C., the concentration is 9%, and the soaking time is 10 minutes; the pH of the acidic solution is 5, the temperature is 40° C., and the soaking time is 6 hours.

[0034] Cook in the step (2) for 2 hours and then wash it with clear water after being fished out. The thickness of the corn paved on the stainless steel mesh layer frame is 3cm. The first aging time is 72 hours, the constant temperature drying temperature is 70°C, the water content of the corn after constant temperature drying is 14%, and the second aging time is 5 days.

[0035] The frying time in the step (3) is 3 minutes, the oil temperature is controlled at 210° C., immersed in cold coconut oil for 1 minute, removed and drained for 1 minute, and coated with flour when the temperature drops to 50° C.

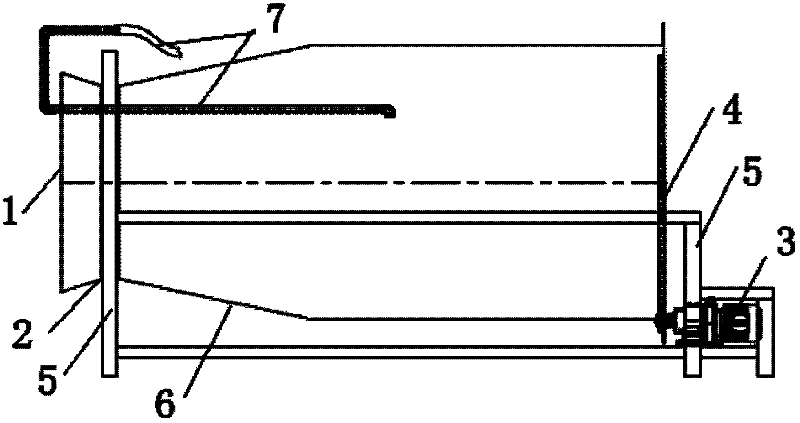

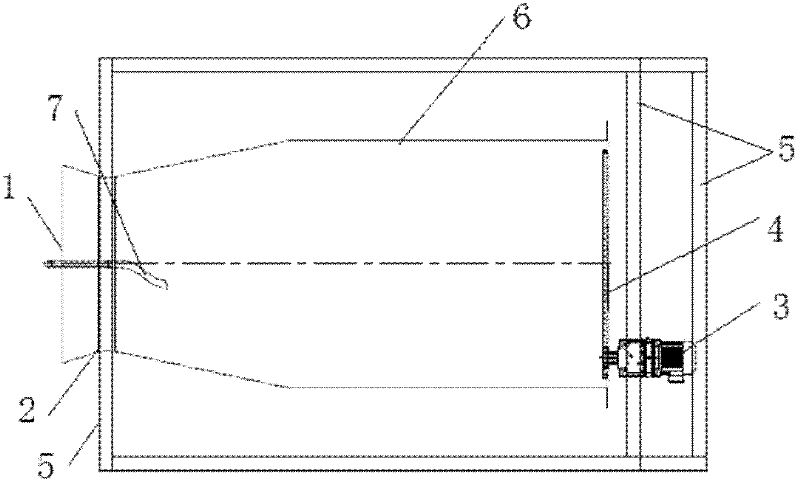

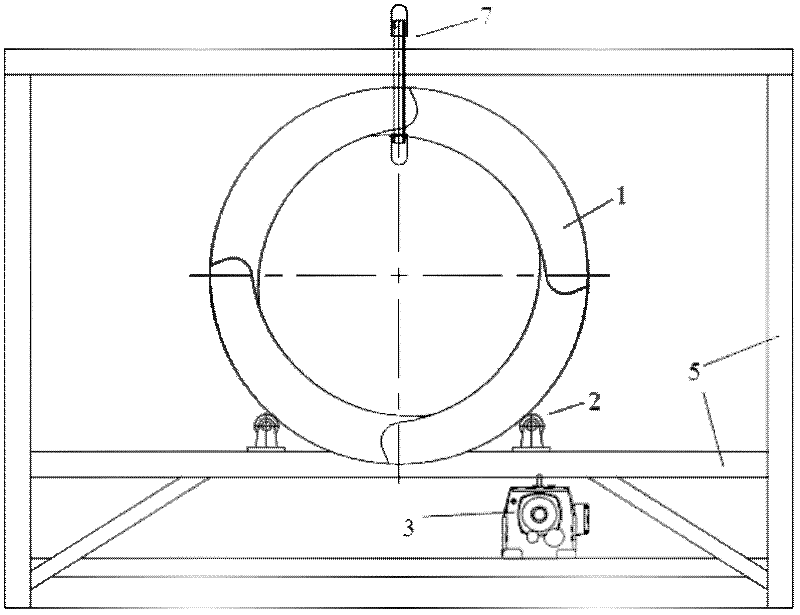

[0036] Combine below Figure 1 to Figure 3 Specifically illustrate the peeling machine among the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com