Method for fabricating ant nest casting mould

A production method and technology of ant nests, applied in the fields of pest control and entomology, can solve the problems of fragile molded products, high cost, and distortion of molded products, so as to avoid mold distortion, high toughness and elasticity, and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

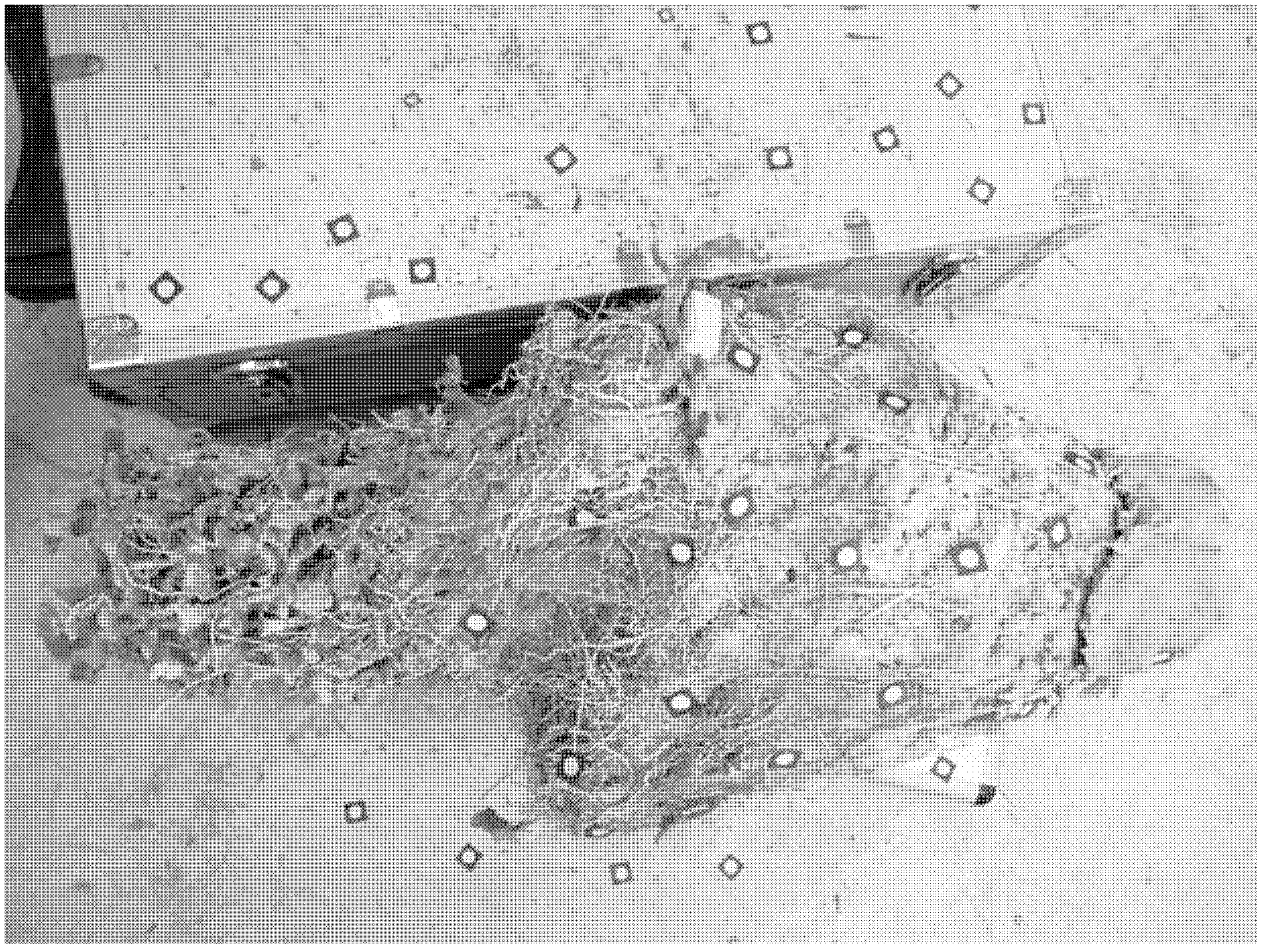

[0027] Embodiment 1, the making of multi-ant queen type red imported fire ant nest mold

[0028] (1) In the field of Danshuikeng Scenic Area, Huangpu District, Guangzhou City, at 23 ° 14 ' north latitude 23 ° 14 ' east longitude 113 ° 25 ', select the mature red imported imported fire ant nest with many queens, and its anthill height is 40 cm;

[0029] (2) shovel out a circular opening with a diameter of 10 cm at the top of the anthill;

[0030] (3) Use 20g of AB glue to vertically and tightly bond a PVC pipe with a height of 35cm and a diameter of 10cm to the circular opening as an injection pipe;

[0031] (4) Weigh 15 kg of Shenzhen Coca (COCA) RTV-2-8310# mold special silica gel (i.e. polysiloxane, with a degree of polymerization of 100), and add 610 ml of blue RTV-2 produced by Dongguan Liangcai Pigment Co., Ltd. Silicone pigment, quickly drop 230ml of dioctyltin and 540ml of silicone oil, and stir well until the silicone is evenly dyed by the pigment to obtain the pourin...

Embodiment 2

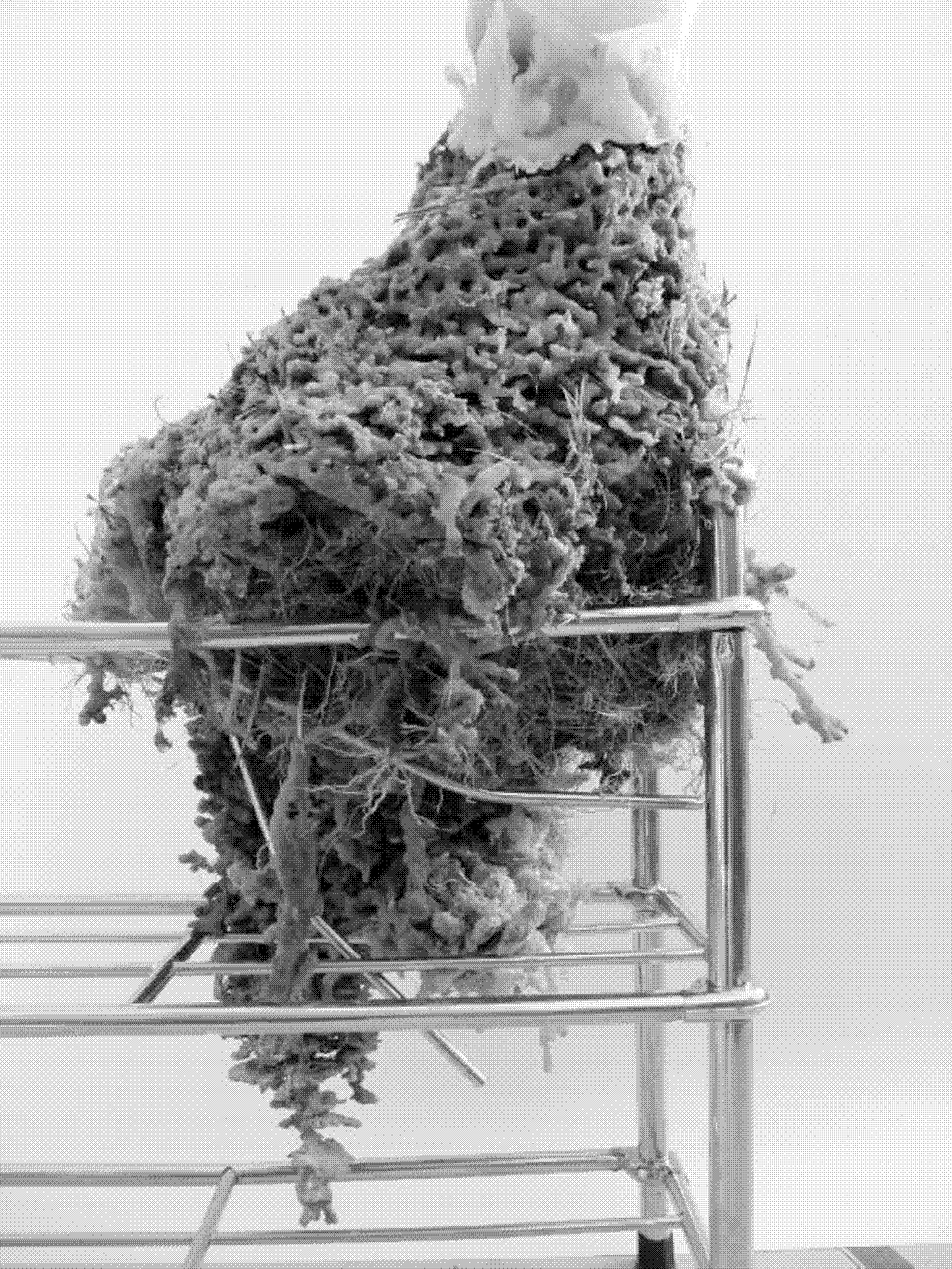

[0036] Embodiment 2, the making of the large-headed ant Pheidole yeensis ant nest mold

[0037] (1) In the field of Danshuikeng Scenic Area, Huangpu District, Guangzhou City, the field of latitude 23°10' north latitude 113°18' east longitude is selected for the mature Yidatou ant nest, and the length and width of the nest mouth are 4.0cm×3.2cm;

[0038] (2) shovel out a circular opening with a diameter of 3 cm at the top of the ant nest;

[0039] (3) Use 8g of AB glue to vertically and tightly bond a PVC pipe with a height of 20cm and a diameter of 3cm to the circular opening as an injection pipe;

[0040] (4) Weigh 3 kg of Shenzhen Solid Plus (COCA) RTV-2-8310# mold-specific silica gel (i.e. polysiloxane, with a degree of polymerization of 2000), quickly drop 60 ml of dibutyltin dilaurate and 135 ml of silicone oil into the Stir to obtain the potting material; wherein, the ratio of mold special silica gel, dibutyltin dilaurate and silicone oil by volume is 100:2.2:5;

[004...

Embodiment 3

[0045] Embodiment 3, the making of single ant queen type RIFA ant nest mold

[0046] (1) In the field of Danshuikeng Scenic Area, Huangpu District, Guangzhou City, at 23 ° 11 ' north latitude 23 ° 11 ' east longitude 113 ° 22 ', select a single queen-type mature red imported imported fire ant nest, and its anthill height is 25 cm;

[0047] (2) shovel out a circular opening with a diameter of 5 cm at the top of the anthill;

[0048] (3) Use 16g of AB glue to vertically and tightly bond a PVC pipe with a height of 23 cm and a diameter of 5 cm on the circular opening as an injection pipe;

[0049] (4) Weigh 12 kg of Shenzhen solid plus (COCA) RTV-2-8310# mold special silica gel (polysiloxane, the degree of polymerization is 1000), quickly drop into 330ml of dioctyltin and cyclopolydimethylsiloxane Alkane (polymerization degree is 50) 1100ml is fully stirred to obtain pouring material; Wherein, the volume-number ratio of mold-specific silica gel, dioctyltin and cyclopolydimethyls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com