Method for improving tensile stress of silicon nitride film in semiconductor devices

A technology of silicon nitride thin film and tensile stress, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The main process of the preferred embodiment of the method for improving the tensile stress of the silicon carbide film of the present invention is as follows:

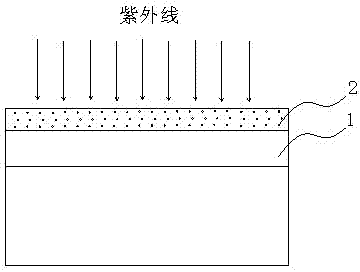

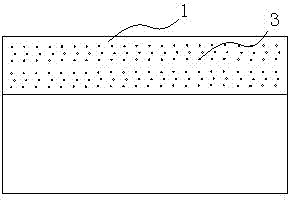

[0018] In the process of depositing the silicon nitride film, a certain amount of organic pore former 3 is added to the silicon nitride film 1, and the organic pore former 3 here is alpha-terpinene (ATRP) or norbornadiene (BCHD). ), etc., such as Figure 2A shown;

[0019] When the film 1 is irradiated with ultraviolet light, part of the Si-H / N-H bonds in the silicon nitride film 1 will break and shrink after obtaining energy. A certain content of hydrogen 2 in film 1, such as Figure 2B shown, and it is known through experiments that the tensile stress of the film is proportional to the shrinkage rate of the film. The data results can be found in image 3 shown, thereby increasing the tensile stress of the silicon nitride film.

[0020] Applying the thin film preparation method to the etch stop layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com