Transfer type magnetic bar

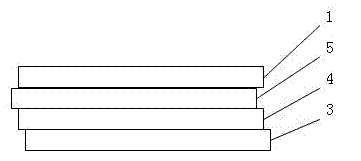

A transfer type, magnetic stripe technology, applied in the field of magnetic stripes, can solve the problems of large magnetic signal interval loss and the difficulty in meeting the standard requirements for output signals of invisible magnetic cards, and achieve the effects of reducing interval loss, wide application range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the adhesive layer is as follows: stirring and sanding titanium dioxide, resin solution, solvent, etc. to prepare the adhesive layer slurry.

[0042] The transfer type magnetic strip without stripping layer provided by the invention can be obtained by the following method:

[0043] Coat the tape base with a peelable magnetic layer by known coating methods such as bar coating, gravure coating, extrusion coating, reverse roll coating, etc., and then coat the adhesive layer on the peelable magnetic layer, dry and cut , to obtain a transfer-type magnetic strip without a peeling layer.

[0044] The present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited thereto.

Embodiment 1

[0046] Strippable magnetic layer slurry preparation

[0047] 100 parts of hydroxyacrylic acid,

[0048] 20 parts of polyester,

[0049] Magnetic powder 500 parts,

[0050] 25 parts of soybean lecithin,

[0051] 25 parts of modified silicone,

[0052] Curing agent (isocyanate) 40 parts,

[0053] 600 parts of toluene,

[0054] Butanone 900 parts,

[0055] Add 100 parts of hydroxyacrylic acid, 20 parts of polyester, 500 parts of magnetic powder, 25 parts of soybean lecithin and 25 parts of modified silicone into 600 parts of toluene and 900 parts of butanone, stir well, and sand Disperse to make a peelable magnetic layer slurry, add 40 parts of curing agent (isocyanate) and set aside.

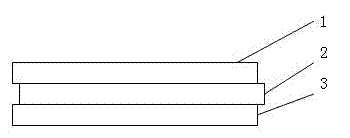

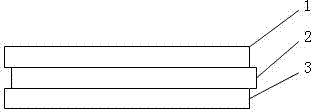

[0056] Coating a strippable magnetic layer on a 20-micron PET tape base, then coating an adhesive layer on the strippable magnetic layer, drying, and slitting to obtain a film with a thickness of 7 microns for a strippable magnetic layer and a thickness of 3 microns for the adhesive layer. ...

Embodiment 2

[0058] Strippable magnetic layer slurry preparation

[0059] Rosin resin 80 parts,

[0060] 30 parts of polyester,

[0061] Magnetic powder 300 parts,

[0062] 15 parts of soybean lecithin,

[0063] Curing agent (amino resin) 20 parts,

[0064] 600 parts of toluene,

[0065] 600 parts of sec-butyl acetate,

[0066] Add 80 parts of rosin resin, 30 parts of polyester, 300 parts of magnetic powder and 15 parts of soybean lecithin into 600 parts of toluene and 600 parts of sec-butyl acetate, stir evenly, and sand mill to disperse to make a peelable magnetic For layering, add 20 parts of curing agent (amino resin) and set aside.

[0067] Coating a peelable magnetic layer on a 20 micron PET tape base, and then coating an adhesive layer on the peelable magnetic layer, drying and slitting to obtain a transfer film with a thickness of 10 microns for a peelable magnetic layer and a thickness of 3 microns for the adhesive layer. Type magnetic strip, measure its performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com