Deodorant for treating biological sludge, preparation method and application of deodorant

A biological sludge and deodorant technology, applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of difficulty in cultivation and preservation of bacterial strains, poor odor treatment effect and reliability and other problems, to achieve the effect of long effective action time, high selectivity and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

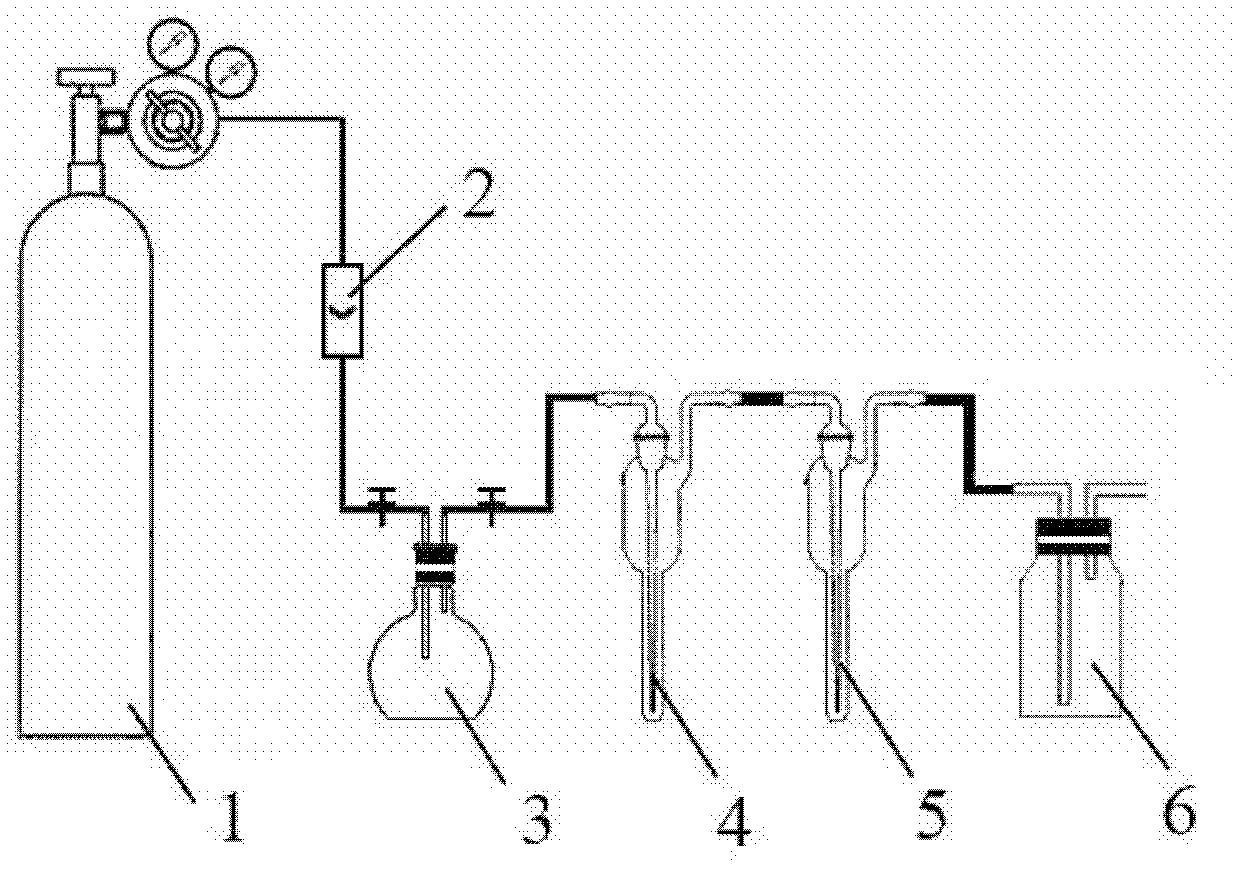

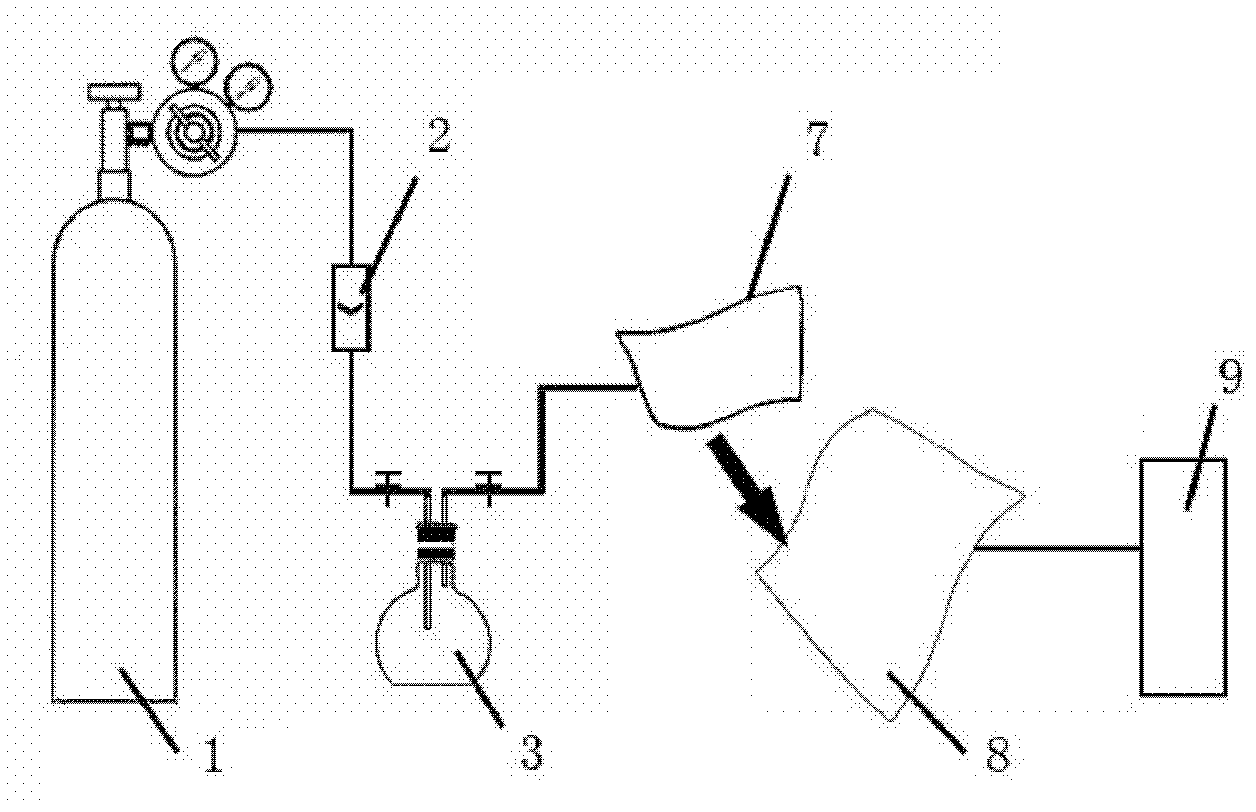

Method used

Image

Examples

Embodiment 1

[0035] The basic properties of mechanically dehydrated biological sludge (1#) from a domestic sewage treatment plant are shown in Table 1:

[0036] Table 1

[0037] nature

moisture content

pH

total sulfur

Zn

Pb

Cr

Cu

unit

%

%

%, dry basis

g / kg, dry basis

g / kg, dry basis

g / kg, dry basis

g / kg, dry basis

value

75.64

8.64

76.20

1.40

1.04

0.05

0.10

0.22

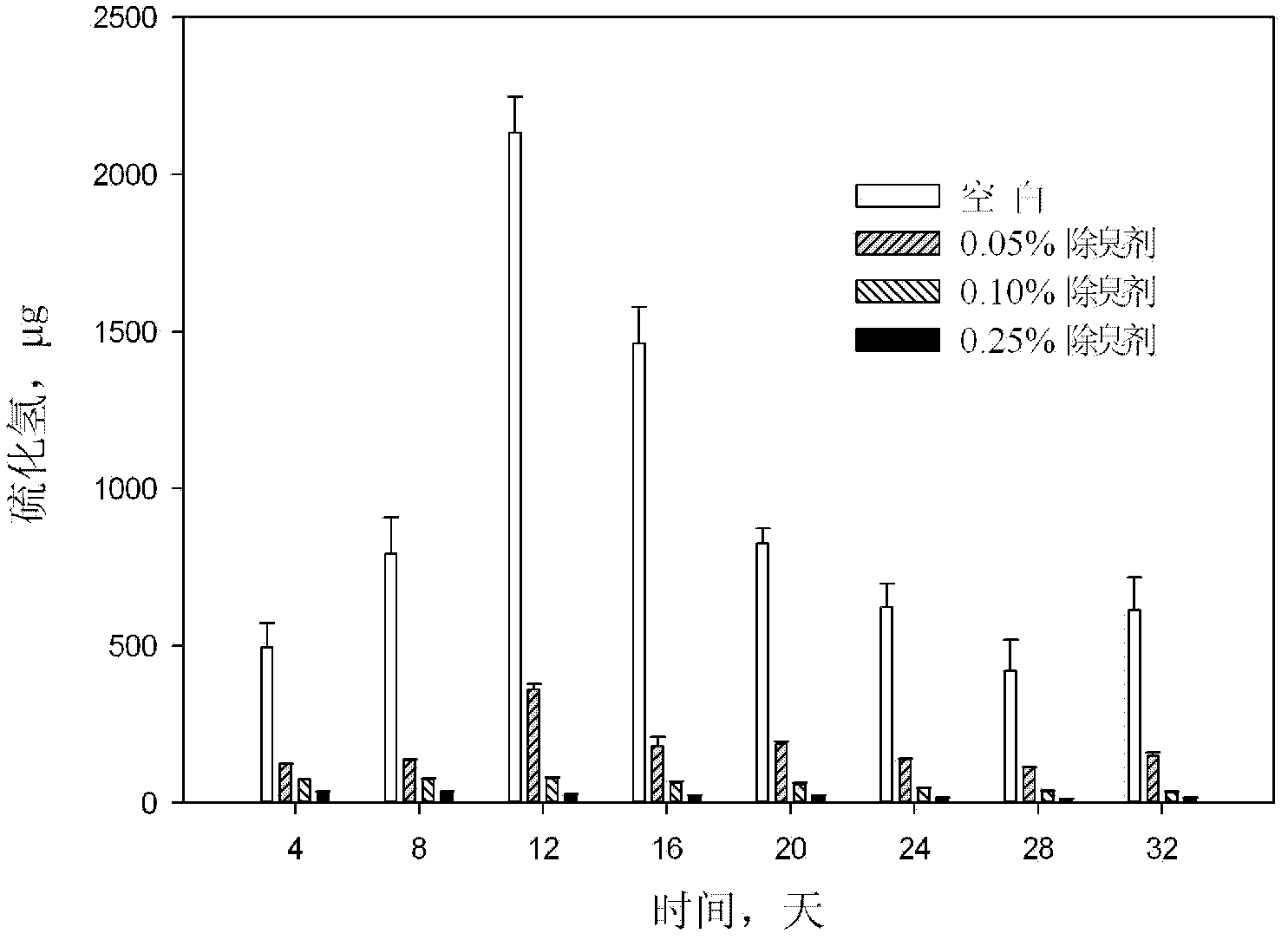

[0038] The preparation method of the sludge deodorizer comprises the following steps: mixing 95.0% by mass of ferric hydroxide, 4.8% by mass of disodium edetate and 0.2% by mass of citric acid, and Grind and pass through a 120-mesh sieve to prepare the sludge deodorant. Add deodorants of 0.05%, 0.10% and 0.25% to the dehydrated biological sludge by spraying, and stir evenly to deodorize. And the dehydrated biological sludge sample without adding sludge deodorizer was use...

Embodiment 2

[0044] Taken from a domestic sewage treatment plant mechanically dehydrated biological sludge (2#), the basic properties are shown in Table 2:

[0045] Table 2

[0046] nature

moisture content

pH

total sulfur

Zn

Pb

Cr

Cu

unit

%

%

%, dry basis

g / kg, dry basis

g / kg, dry basis

g / kg, dry basis

g / kg, dry basis

value

81.19

6.70

45.67

1.23

1.00

0.04

0.10

0.17

[0047] The preparation method of the sludge deodorant comprises the following steps: mixing 90.0% by mass percentage of ferric hydroxide, 9.0% by mass percentage of disodium edetate and 1.0% by mass percentage of citric acid, and Grind and pass through a 120-mesh sieve to prepare the sludge deodorant. Add deodorants in the amount of 0.20% and 0.50% of the mass percentage of biological sludge to the dehydrated biological sludge in a spraying manner, and stir evenly to ...

Embodiment 3

[0050] The basic properties of the biological sludge in the concentration tank of a domestic sewage treatment plant are shown in Table 3:

[0051] table 3

[0052] nature

moisture content

pH

TSS

VSS

total sulfur

Zn

Cr

Cu

unit

%

g / l

g / l

%, dry basis

g / kg, dry basis

g / kg, dry basis

g / kg, dry basis

value

96.91

6.97

13.72

8.42

0.87

1.00

0.10

0.17

[0053] The preparation method of the sludge deodorant comprises the following steps: mixing 85.0% by mass percentage of ferric hydroxide, 13.0% by mass percentage of disodium edetate and 2.0% by mass percentage of citric acid, and Grind and pass through a 120-mesh sieve to prepare the sludge deodorant. In the biological sludge in the concentration pool, add the above-mentioned sludge deodorants with a mass ratio of 0.10% and 0.25% respectively in the form of spraying, and stir evenly to deo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com