N-tetradecyl alcohol phase-change microcapsule and preparation method thereof

A technology of phase-change microcapsules and n-tetradecyl alcohol, which is applied in the field of polymer composite material preparation, can solve the problems of easy agglomeration of emulsions, difficult microencapsulation, and difficult emulsification, and achieves good water resistance, uniform particle size, and high water resistance. The effect of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

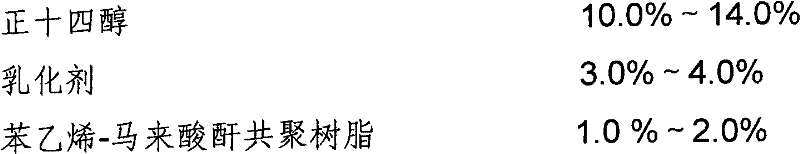

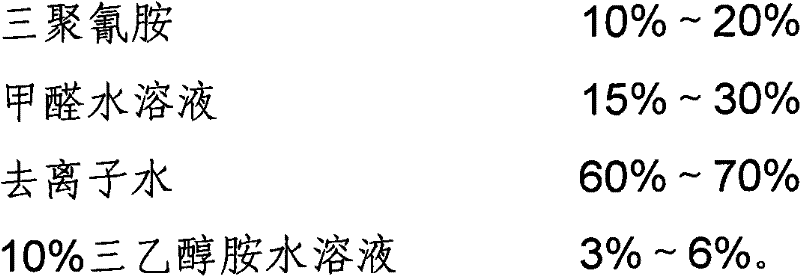

[0032] The preparation method of n-tetradecyl alcohol phase-change microcapsules, carries out batching according to above-mentioned components and proportioning thereof, and its steps are:

[0033] The preparation steps of n-tetradecyl alcohol emulsion are:

[0034] (1) Add the styrene-maleic anhydride copolymer resin, sodium hydroxide and emulsifier into the deionized water, mix, heat in a water bath at 60°C, stir evenly to obtain the styrene-maleic anhydride copolymer resin sodium salt solution, Then use 10% citric acid aqueous solution to adjust the pH=4 to 5 to make an emulsifier aqueous solution for subsequent use;

[0035] (2) n-tetradecyl alcohol is added in the emulsification reactor, heated and melted;

[0036] (3) At a stirring speed of 1000r / min, divide the emulsifier aqueous solution into 5 parts and add them to the emulsification reaction kettle in batches, with an interval of 5 minutes each time. After the last batch of emulsifier aqueous solution is added, dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com