Lubricating grease composition for seat slide rails of automobile

A technology of grease composition and car seat slide rail, which is applied in the direction of lubricating composition, petroleum industry, thickener, etc., and can solve the problems of decreased lubricating performance, accompanied by noise, increased seat friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

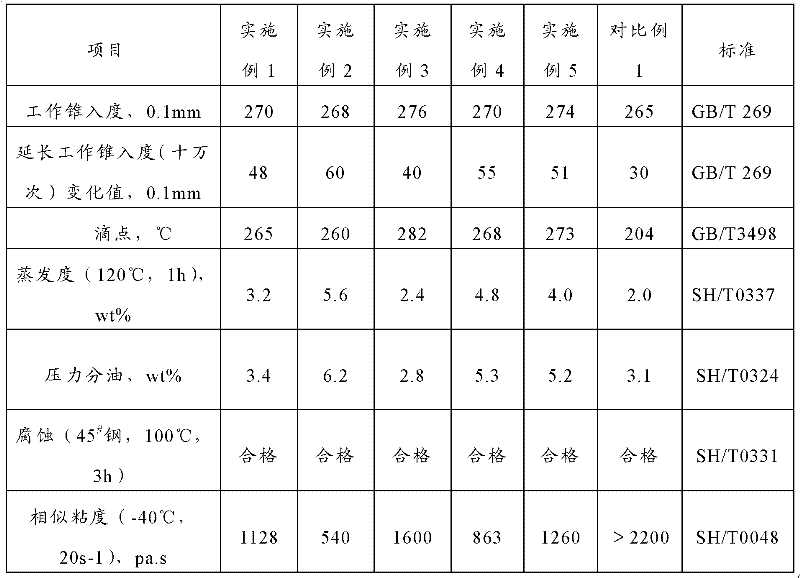

Embodiment 1

[0032] Select 10 parts of dipolyurea thickener and 90 parts of HV1150 base oil according to the weight ratio and stir evenly. The 100°C kinematic viscosity of the HV1150 base oil is 5.5mm 2 / s,; stir and heat up to 130°C, keep for 30 minutes; mix 1 part of 2,6-di-tert-butyl-p-cresol; cool to room temperature, add 1 part of sodium petroleum sulfonate, stir well, and finally use three-wheel mill Grind 3 times to obtain a grease composition. The physical and chemical properties of the resulting grease are shown in Example 1 in Table 1.

Embodiment 2

[0034] Select 30 parts of dipolyurea thickener and 70 parts of PAO2 base oil by weight and stir evenly, the 100 ℃ kinematic viscosity of described PAO2 base oil is 2mm 2 / s,; stir and heat up to 130°C, keep for 30 minutes; mix 1 part of 2,6-di-tert-butyl-p-cresol; cool to room temperature, add 1 part of sodium petroleum sulfonate, stir well, and finally use three-wheel mill Grind 3 times to obtain a grease composition. The physical and chemical properties of the resulting grease are shown in Example 2 in Table 1.

Embodiment 3

[0036] Select 20 parts of dipolyurea thickener and 90 parts of HV1150 base oil and 90 parts of PAO10 base oil by weight and stir evenly, and the kinematic viscosity of the HV1150 base oil is 5.5mm2 / s, the kinematic viscosity of PAO10 base oil at 100°C is 10mm 2 / s; stir and heat up to 140°C, keep for 30 minutes; mix 1 part of 2,6-di-tert-butyl-p-cresol evenly; cool to room temperature, add 1 part of sodium petroleum sulfonate, stir evenly, and finally grind with a three-wheel mill 3 times to obtain a grease composition. The physical and chemical properties of the resulting grease are shown in Example 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com