Preparation method and application of texture structure ZnO thin film on glass substrate

A glass substrate and thin film technology is applied in the field of transparent conductive oxide thin films to achieve the effects of improving photoelectric conversion efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

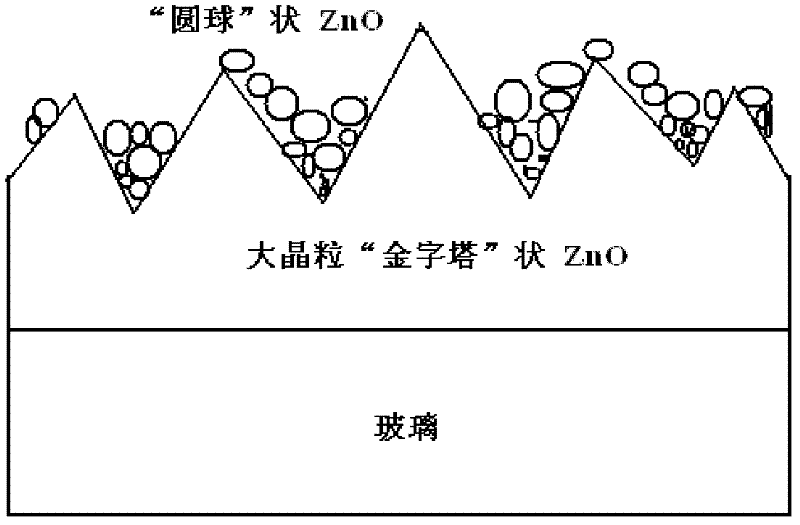

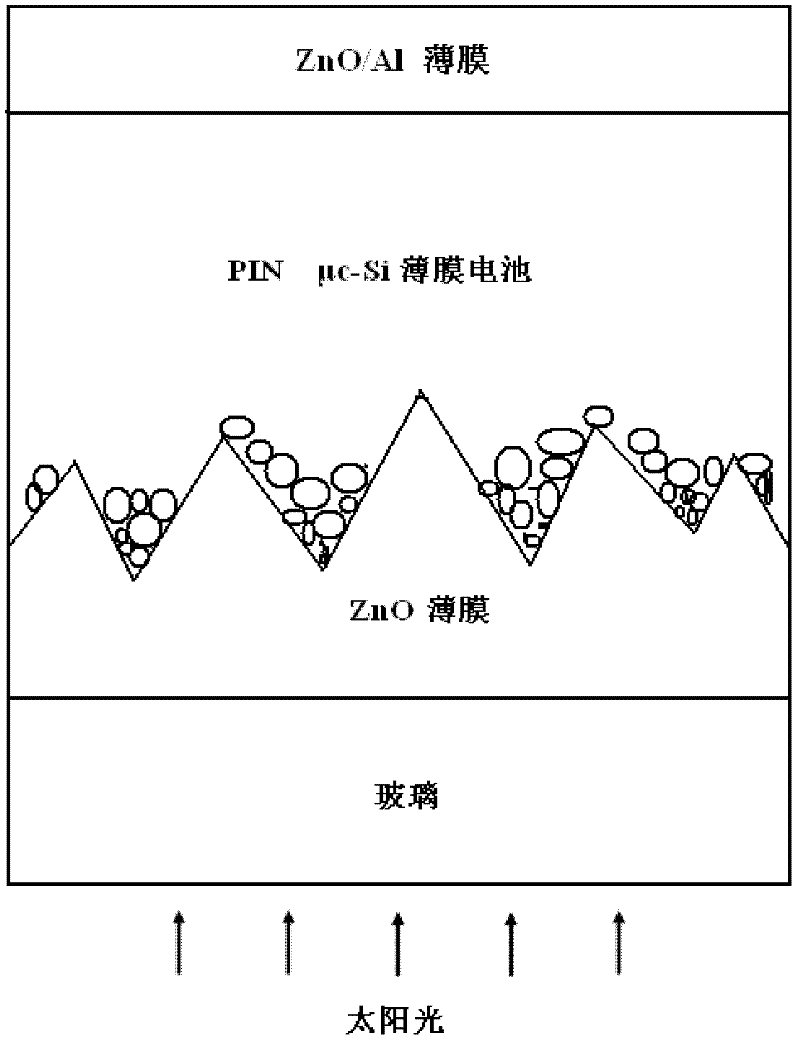

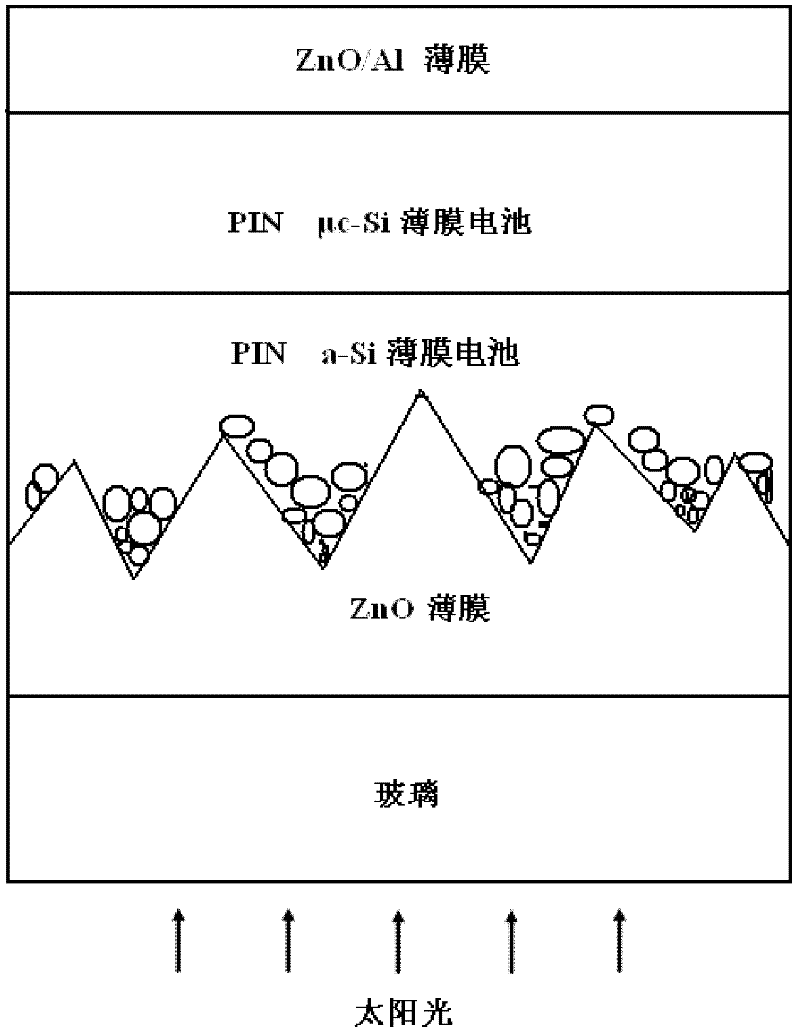

[0021] A method for preparing a ZnO film with a textured structure on a glass substrate, using diethyl zinc and water with a purity of 99.995% as source materials, and borane B 2 h 6 For the doping gas, dilute the doping gas borane B with hydrogen 2 h 6 , doping gas borane B 2 h 6 The volume percent concentration in the gas mixture is 1%, and metal-organic chemical vapor deposition (MOCVD) is used to grow a textured ZnO-TCO film on a glass substrate, which is carried out in two steps:

[0022] 1) First, grow a layer of ZnO film with a large grain size "pyramid-like" structure on a glass substrate, the substrate temperature is 155 ° C, the coating reaction pressure is 130 Pa, and the film thickness is 1550 nm;

[0023] 2) Then grow a layer of ZnO film with small grain size "spherical" structure on the above-mentioned "pyramid-like" structure ZnO film, the substrate temperature is 135°C, and the film thickness is 500nm.

[0024] The structure of the textured ZnO thin film o...

Embodiment 2

[0028] A method for preparing a ZnO film with a textured structure on a glass substrate, using diethyl zinc and water with a purity of 99.995% as source materials, and borane B 2 h 6 For the doping gas, dilute the doping gas borane B with hydrogen 2 h 6 , doping gas borane B 2 h 6 The volume percent concentration in the mixed gas is 1%, and metal-organic chemical vapor deposition (MOCVD) is used to grow a textured ZnO-TCO film on a glass substrate, which is carried out in two steps:

[0029] 1) First, grow a layer of ZnO film with a large grain size "pyramid-like" structure on a glass substrate, the substrate temperature is 155°C, the coating reaction pressure is 130Pa, and the film thickness is 2000nm;

[0030] 2) Then grow a layer of ZnO film with small grain size "spherical" structure on the above-mentioned "pyramid-like" structure ZnO film, the substrate temperature is 135°C, and the film thickness is 350nm.

[0031]The structure of the textured ZnO thin film on the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com