High-precision multi-frequency phase-synchronized laser distance measurement device and method

A technology of synchronizing phase and laser ranging, applied in the directions of measuring device, measuring distance, surveying and navigation, etc., can solve the problem of lack of multiple measuring rulers, and achieve the effect of eliminating drift and jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

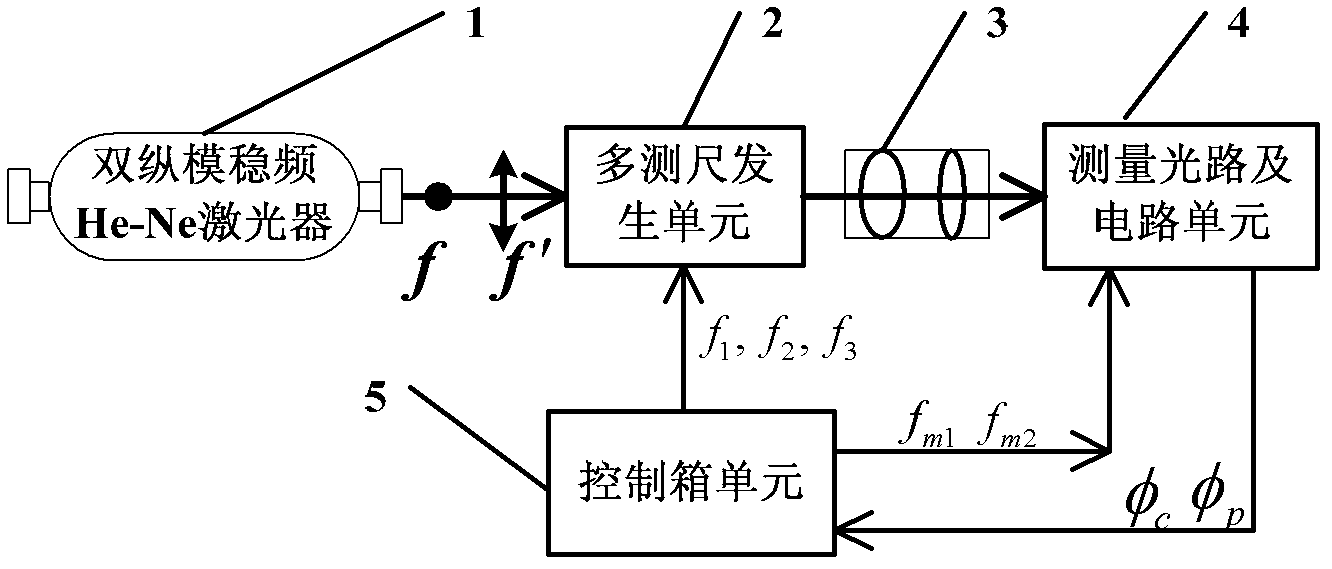

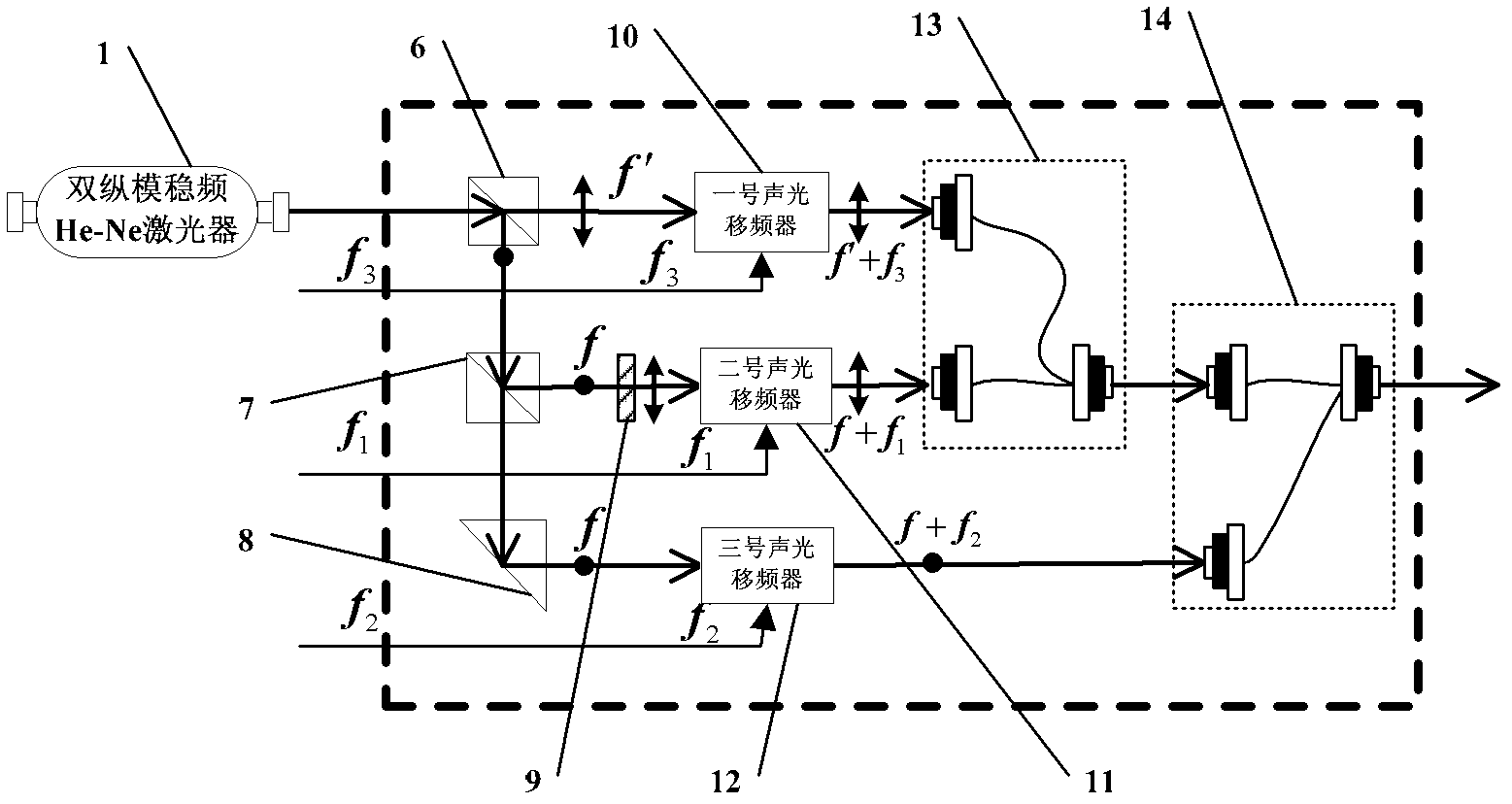

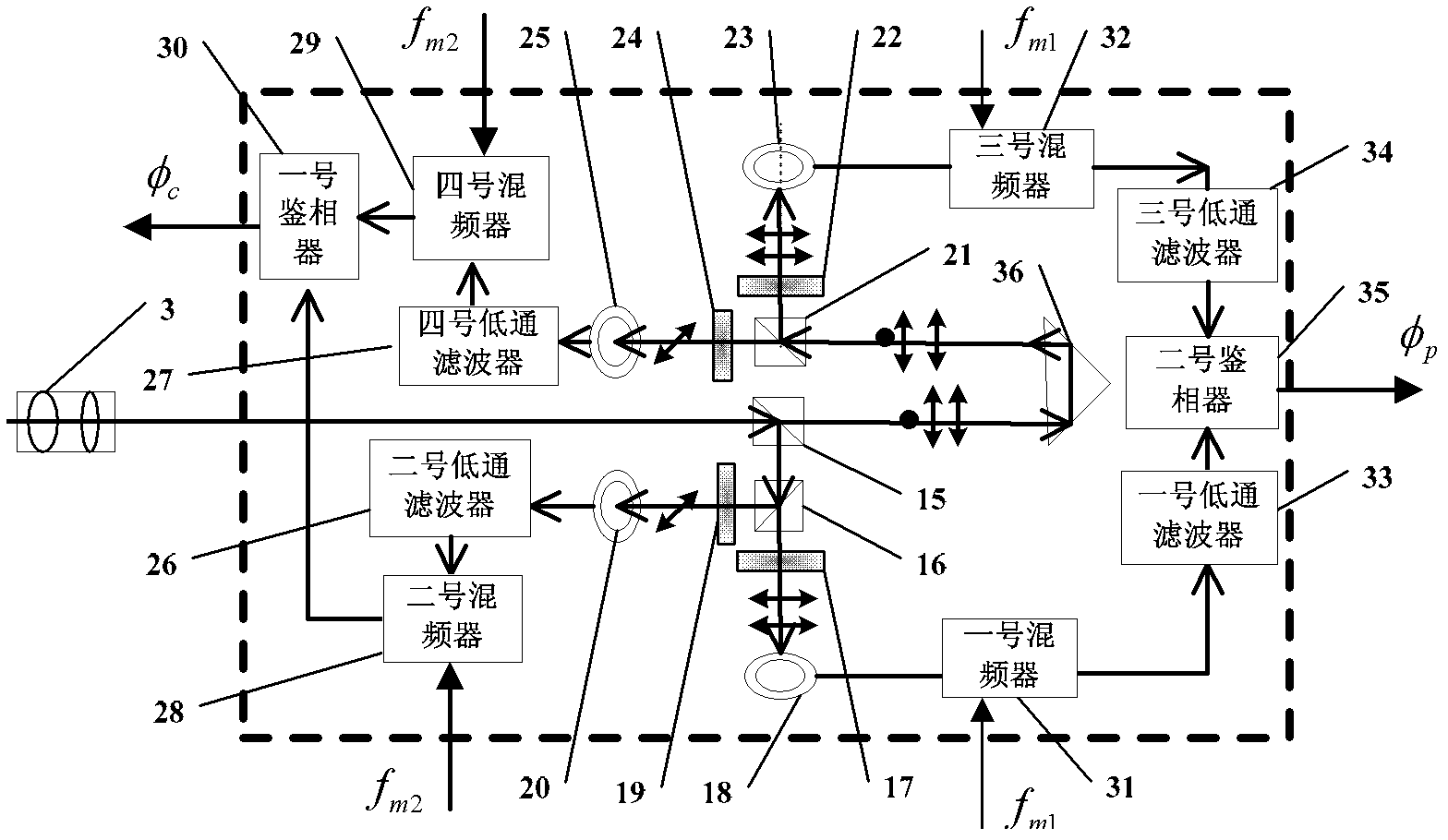

[0024] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Description of this embodiment, a high-precision multi-frequency synchronous phase laser ranging device, which consists of a dual longitudinal mode frequency-stabilized He-Ne laser 1, a multi-scale generating unit 2, a beam expanding collimating mirror group 3, a measuring optical path and a circuit unit 4 Composed of the control box unit 5, the laser output from the dual longitudinal mode frequency-stabilized He-Ne laser 1 is output to the input end of the multi-scale generating unit 2, and the laser output from the multi-scale generating unit 2 passes through the beam expander collimating mirror group 3 to the The input end of the measurement optical path and the circuit unit 4, the phase information output end of the measurement optical path and the circuit unit 4 are connected to the phase information input end of the control box unit 5, and one control output end of the contr...

specific Embodiment approach 2

[0028] Embodiment 2: Different from Embodiment 1, the crystal oscillator 38 of this embodiment adopts a temperature-compensated crystal oscillator, and the short-term frequency stability is better than 0.01ppm. Other components and connections are the same as Embodiment 1.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 Illustrate this embodiment, adopt the high-precision multi-frequency synchronous phase laser ranging device described in the specific embodiment one to realize the high-precision multi-frequency synchronous phase laser ranging method, and its specific steps are as follows:

[0030] Step 1. Turn on the dual-longitudinal-mode frequency-stabilized He-Ne laser 1. After preheating and frequency stabilization, the dual-longitudinal-mode frequency-stabilized laser 1 outputs dual-frequency lasers with frequencies f and f′ respectively. The dual-frequency laser passes through The polarization beam splitter 6 is divided into two beams of laser beams whose polarization states are perpendicular to each other, wherein the laser beam with a frequency of f is divided into two beams through the beam splitter prism, and one of the laser beams passes through the polarization rotator, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com