Air guiding heat dissipation device for computer

A technology of heat dissipation device and air guide device, which is applied in computing, instrumentation, electrical and digital data processing, etc., can solve the problems of temperature rise, unavoidable noise, affecting heat dissipation effect, etc., and achieve the effect of reducing heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

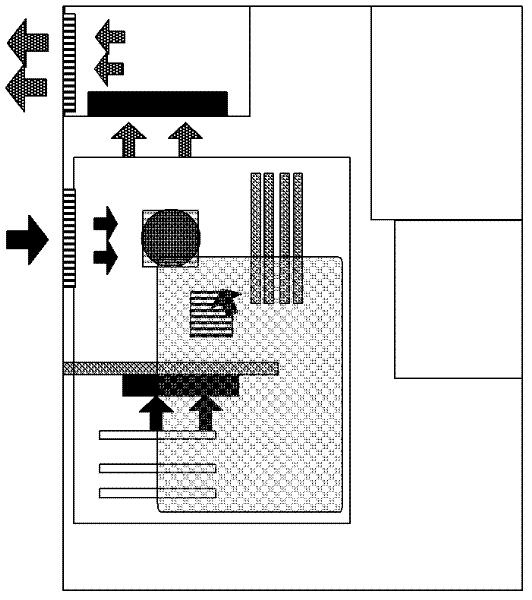

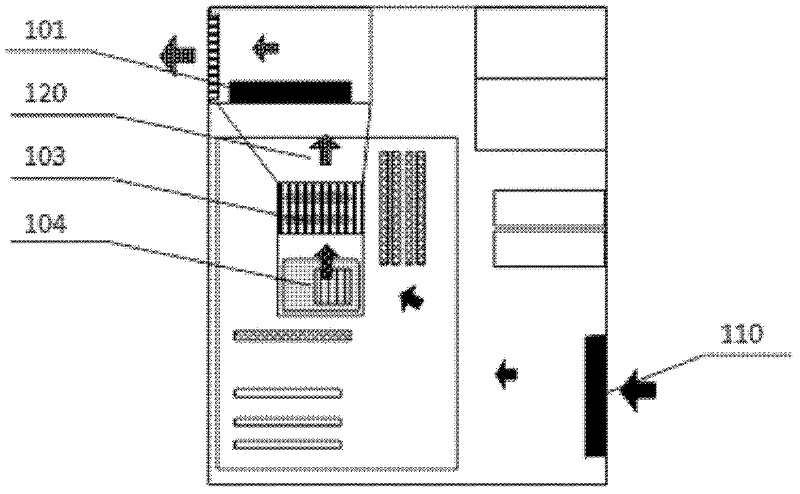

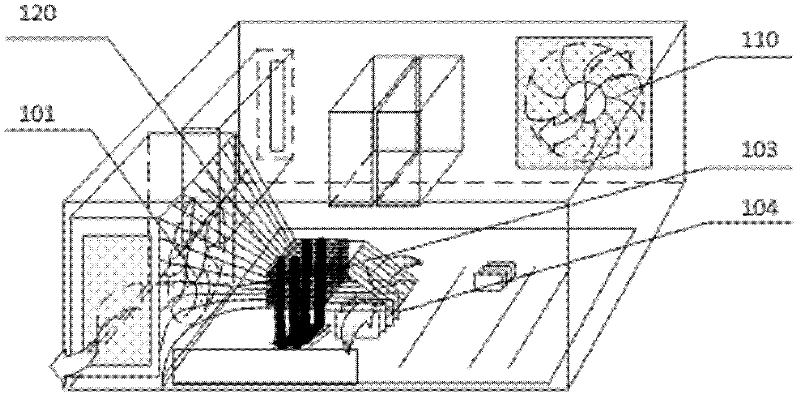

[0035] figure 2 , image 3 It is a schematic diagram of plane and three-dimensional structure of a general performance computer installed with the air guide and heat dissipation device of the present invention. The machine is a general-purpose ATX vertical structure, equipped with a dual-core CPU with a maximum power consumption of 65W, and an integrated graphics card. The chassis power supply is an active high-efficiency power supply with a rated power of 200W and a 120mm-caliber fan. A fan, a radiator with a heat pipe is used on the CPU. The port of the large-diameter area of the air-guiding heat-dissipating device is closely attached to the air inlet of the power supply of the chassis, the CPU heat sink is embedded in the port of the small-diameter area of the air-guiding heat-dissipating device, and the end mask of the small-diameter area of the air-guiding heat-dissipating device is above the north bridge radiator of the main board. Pull out the fan wire from the...

Embodiment 2

[0040] Figure 4 , Figure 5 It is a schematic diagram of plane and three-dimensional structure of a high-performance computer installed with the air guide and heat dissipation device of the present invention. The machine is a general-purpose ATX vertical structure, equipped with a 4-core CPU with a maximum power consumption of 95W and a high-end graphics card with a maximum power consumption of 125W. The power supply of the chassis is an active high-efficiency power supply with a rated power There is a 120mm caliber graphics card cooling fan. Install a radiator with heat pipes and corresponding air guide cooling devices on the CPU and graphics card. Pull out the fan wire from the power box of the chassis and connect it to the fan reducer together with the graphics card cooling fan wire.

[0041] Heat dissipation process: (1) Upper part: cold air enters the case from the air inlet 110 on the front panel, passes through the north bridge radiator 104 of the motherboard, enters th...

Embodiment 3

[0044] Figure 6 , Figure 7 Schematic diagram of the plane and three-dimensional structure of an ultra-high-performance computer installed with the air guide and heat dissipation device of the present invention:

[0045] The chassis is a general-purpose ATX vertical structure, equipped with a 6-core CPU with a maximum power consumption of 125W and a top-level graphics card with a maximum power consumption of 250W. The chassis power supply is an active high-efficiency power supply with a rated power of 500W and a 120mm diameter fan. The air inlet of this machine is on the side panel and the rear baffle, and the radiator with heat pipe and the corresponding air guide and heat dissipation device are installed on the CPU and the graphics card. Because the graphics card generates a lot of heat under high load, an air guide cooling device with two 120mm diameter fans is installed, and the fan wires are pulled out from the power supply box and connected to the fan reducer together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com