Non-dewetting porous membranes

一种亲水性基团、氟碳的技术,应用在膜、膜技术、半透膜分离等方向,能够解决薄多孔膜破裂、昂贵、密封孔膜耗时等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0135] General Synthetic Methods and Test Procedures

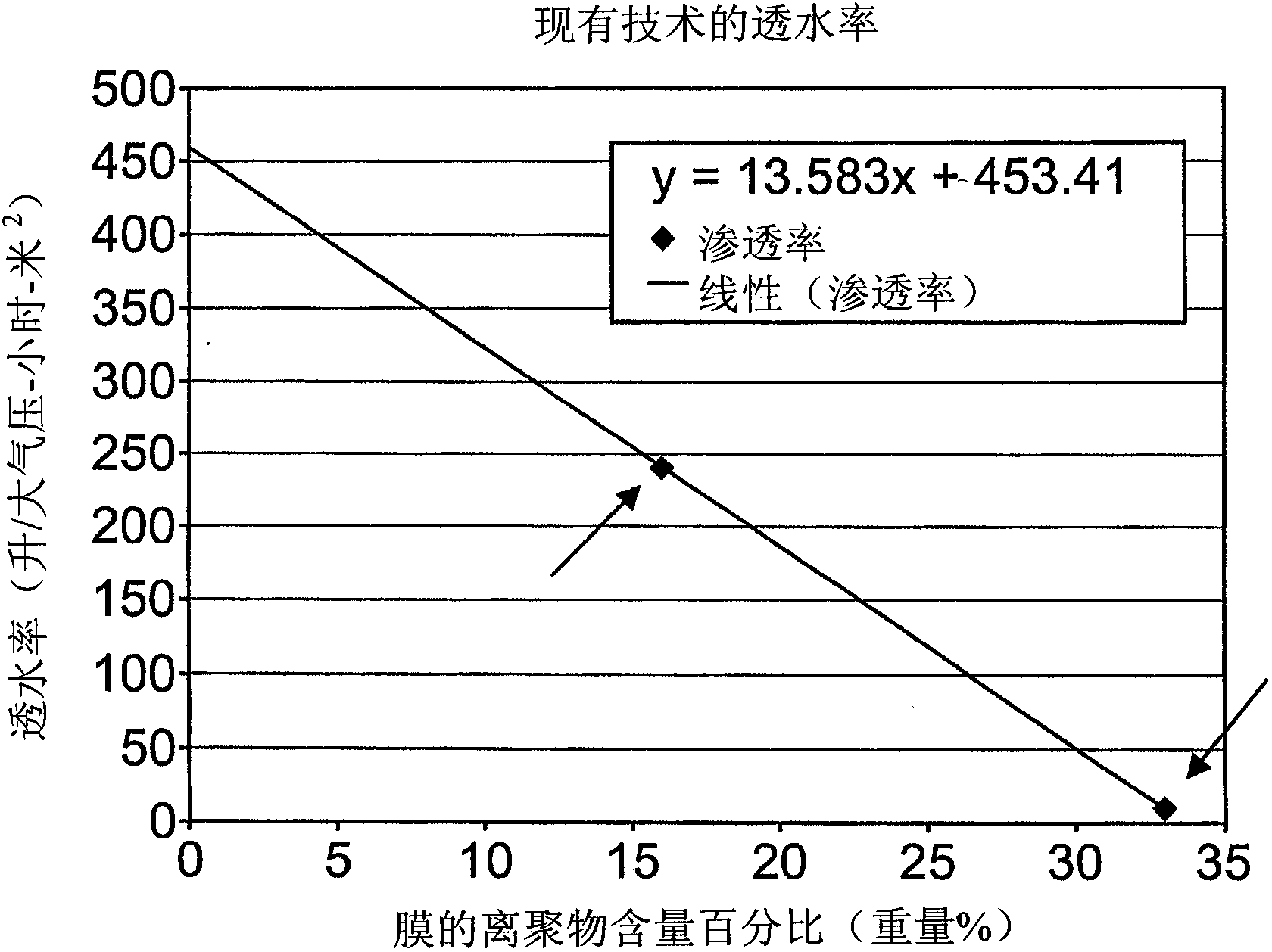

[0136] A fluorocarbon liquid composition comprising from about 0.4 wt% to about 4 wt% of one or more fluorinated ionomers having an equivalent weight of from about 380 g / equivalent to about 620 g / equivalent (as in Table 3 of Example 2 described in ) to coat microporous membrane supports. Fluorinated ionomers derived from CF 2 = CF-O-CF 2 CF 2 SO 2 F monomer unit, tetrafluoroethylene, formula CH 2 =CH-(CF 2 ) 6 -CH=CH 2 The diene unit and iodinated chain transfer agent I-(CF 2 ) 4 -I. Dissolve the ionomer in a fluorocarbon solvent such as methyl perfluorobutyl ether (Novik TM HFE-7100), perfluoropolyether solvents (such as glue SV90) or a combination of these. These ionomer solutions were obtained from Solvay Sulex and optionally filtered prior to use using a filtration microporous membrane of 0.45 micron, 0.2 micron or smaller nominal pore size. Non-limiting examples of combinations of ionomers, free radica...

example 1

[0158] According to the emulsion polymerization procedure disclosed in U.S. Patent No. 6,902,676, by combining TFE with formula CF 2 = CF-O-CF 2 CF 2 -SO 2 Copolymerize vinyl ethers of F to obtain copolymers using the formula CH 2 CH-C 6 f 12 -CHCH 2 Diolefins as pre-crosslinkers, using I-C 4 f 8 -I as chain transfer agent and potassium persulfate as free radical initiator. Copolymers C1, C2, C3 and C4 were obtained under the following conditions shown in Table 2:

[0159] Table 2. Conditions for obtaining copolymers C1, C2, C3 and C4.

[0160]

example 2

[0162] This example discloses the preparation of a fluorinated ionomer coating solution for use in forms of the invention. The pre-crosslinked perfluoroionomer (with iodine chain ends) prepared in Example 1 was dissolved in a partially fluorinated or perfluorinated solvent to achieve a final concentration of about 4 wt%. The mixture was then centrifuged at 10,000 rpm for two hours. A solution S2 * Centrifuge for an additional two hours at 20,000 rpm. A clear transparent liquid was obtained after removal of the insoluble residue, which exhibited the physical properties summarized in Table 3 below:

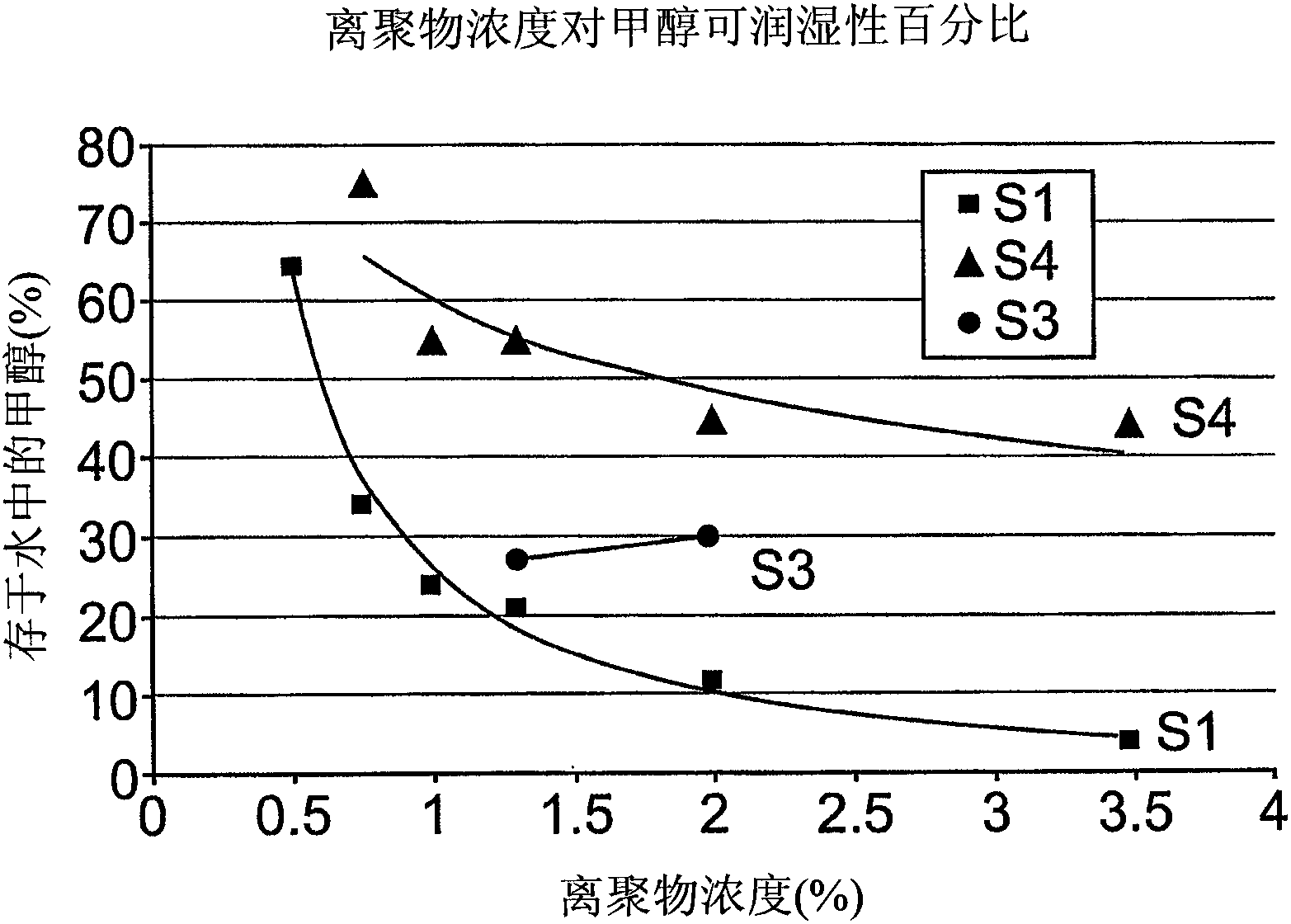

[0163] Table 3. Solutions S1, S2, S2 * , physical properties of S3 and S4.

[0164]

[0165] After dissolving 40 mg of the copolymer in 0.6 ml of hexafluorobenzene, the molar percentage of comonomer was determined by means of NMR and the equivalent weight was subsequently calculated.

[0166] The iodine content of the ionomer was measured by X-ray fluorescence (XRF) and meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com