Negative electrodes for secondary battery, copper foil for electrode, secondary battery, and processes for producing negative electrodes for secondary battery

A technology for secondary batteries and manufacturing methods, which is applied in the field of copper foil for negative electrodes and lithium-ion secondary batteries, and can solve the problems of shortened charge-discharge cycle life, low value and smaller secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

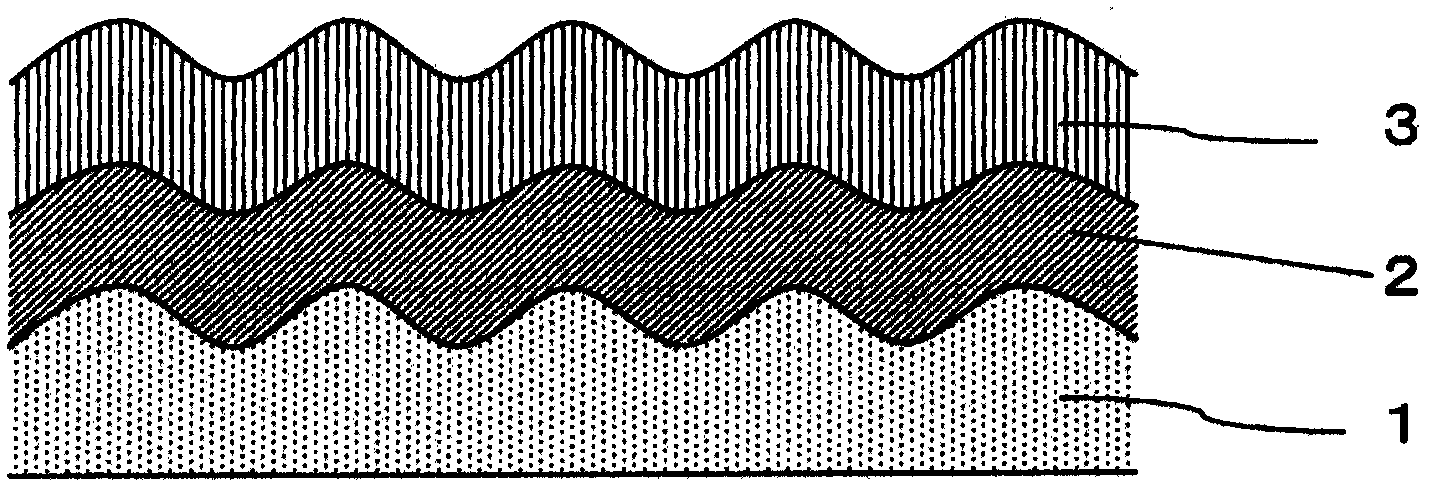

[0061] The negative electrode for a secondary battery according to the first embodiment is provided in the following configuration: a silicon-based active material containing silicon hydride with a hydrogen content of at least 0.1 atomic% is formed on a current collector substrate using copper foil Envelope. In addition, the negative electrode for a secondary battery according to the first embodiment is used and assembled with other constituent materials such as a positive electrode, a separator, and an electrolyte to form a secondary battery, thereby providing the secondary battery according to the first embodiment.

[0062] First, as the base material (current collector base material) of the current collector used for the negative electrode for the secondary battery of the first embodiment, copper foil can be used. Since the volume of the active material expands or contracts due to the insertion and removal of Li ions during charging and discharging, it is preferable to use a c...

no. 2 approach

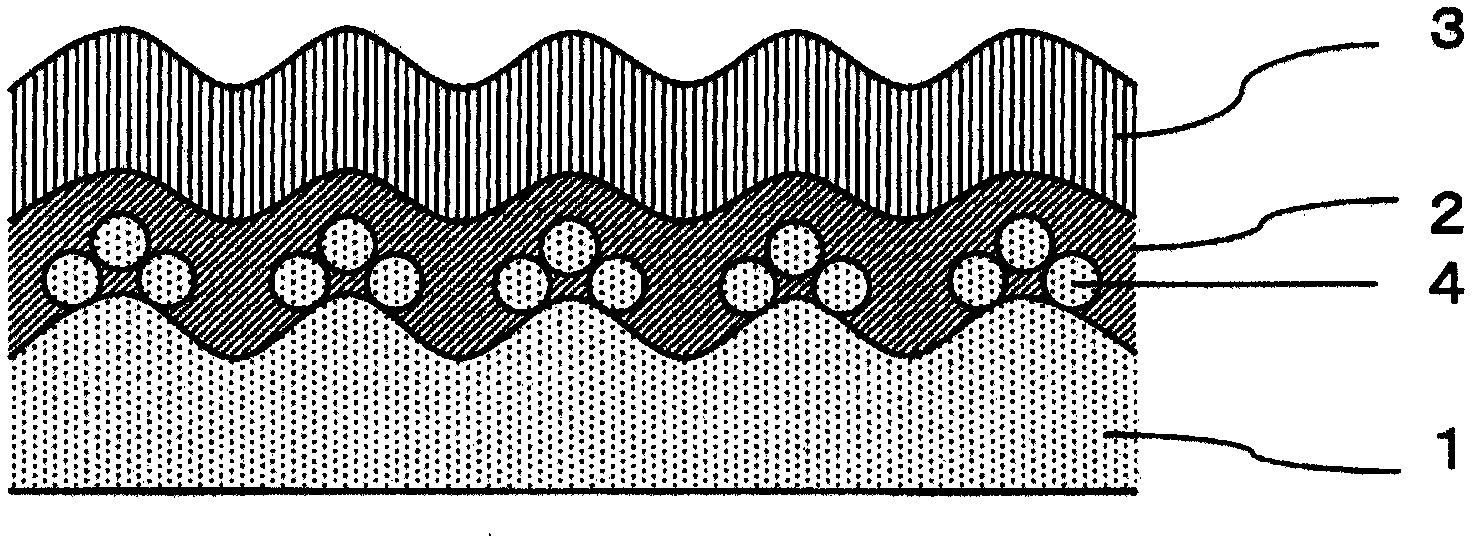

[0088] As the base material (current collector base material) of the current collector used for the negative electrode for the secondary battery of the second embodiment, copper foil can be used. Since the volume of the active material expands and contracts due to the insertion and detachment of Li ions during charging and discharging, it is preferable to use copper foil with an elongation of 3% or more, which is a tensile test at a high temperature of 180°C. The elongation at break is more preferably used in the sense that it can follow the expansion and contraction caused by charge and discharge, and the elongation at break is 5% or more. In addition, the tensile strength of the copper foil used for the current collector substrate is preferably in the range of 300 MPa to 1000 MPa (1 GPa).

[0089] In addition, as for the copper foil used for the current collector base material, only the copper foil whose surface is not smooth and does not have gloss, and at least the surface on...

no. 3 approach

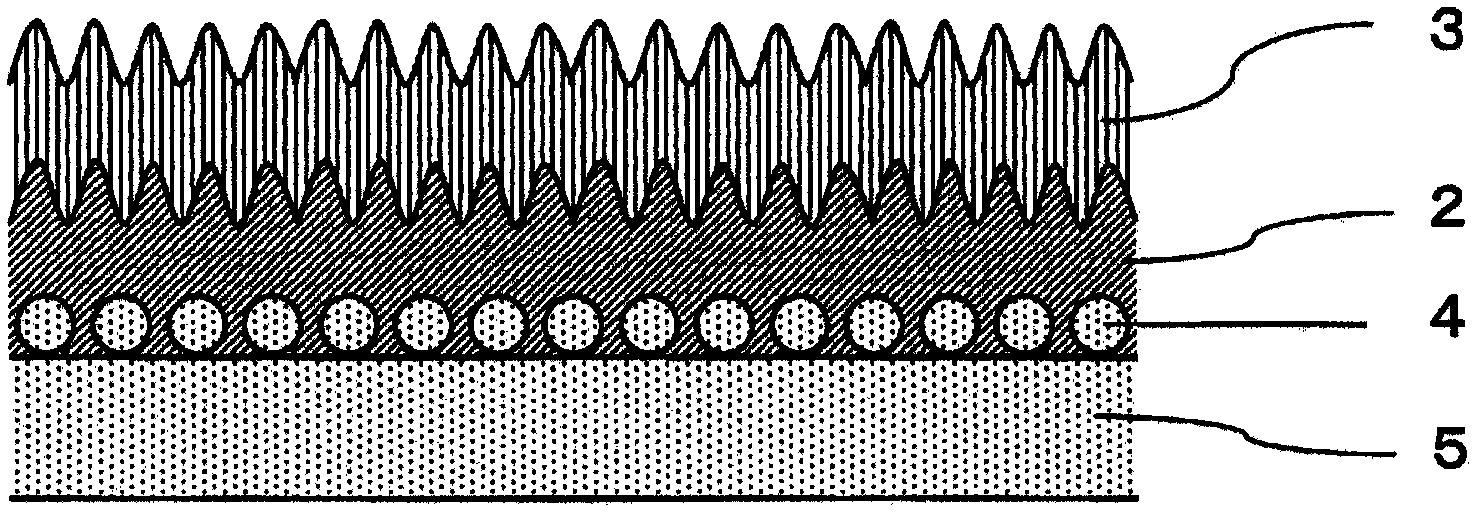

[0107] As the base material (current collector base material) of the current collector used for the negative electrode for secondary batteries of the third embodiment, copper foil can be used. Since the volume of the active material expands and contracts due to the insertion and detachment of Li ions during charging and discharging, it is preferable to use copper foil with an elongation of 3% or more, which is a tensile test at a high temperature of 180°C. The elongation at break is more preferably used in the sense that it can follow the expansion and contraction caused by charge and discharge, and the elongation at break is 5% or more. In addition, the tensile strength of the copper foil used for the current collector substrate is preferably in the range of 300 MPa to 1000 MPa (1 GPa).

[0108] In addition, as for the copper foil used for the current collector base material, only the copper foil whose surface is not smooth and does not have gloss, and at least the surface on wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com