Preparation method of core-shell structure collagen polypeptide chelated calcium nanoparticle

A technology of collagen peptides and nanoparticles, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of complicated preparation methods and large capsule size, and ensure absorption and utilization , easy to absorb, overcome the effect of easy enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

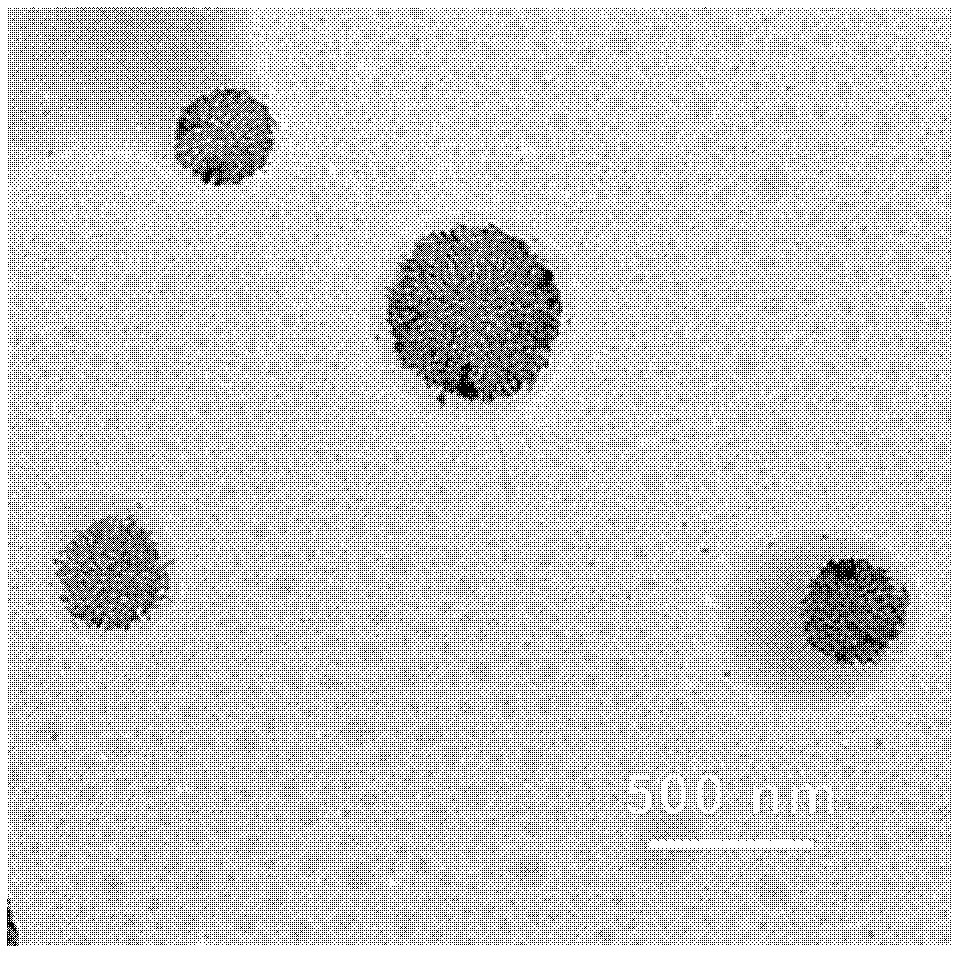

[0020] Take 15ml of 0.03g / ml collagen peptide chelated calcium aqueous solution and slowly add to 7.5ml of 0.018mol / L CaCl 2 In the aqueous solution, stir evenly and fully, adjust the pH to 7.2 to obtain solution A; take 117.5mL 0.63g / L sodium alginate solution, adjust the pH to 7.2, then slowly add solution A dropwise, and keep stirring throughout the process to make it fully reacted. After the solution A is added, the stirring is continued for 30-60 minutes to obtain calcium alginate / collagen polypeptide chelated calcium nanoparticles with core-shell structure. The prepared calcium alginate / collagen polypeptide chelated calcium nanoparticles with a core-shell structure are spherical nanoparticles with a smooth surface, and the particle diameter ranges from 200 to 1000 nm.

[0021] figure 1 The transmission electron microscope image of the prepared core-shell structure collagen polypeptide chelated calcium nanoparticles is given. The sample particle size in the figure is abo...

Embodiment 2

[0023] Take 15ml of 0.1g / ml collagen polypeptide chelated calcium solution and slowly add to 7.5ml of 0.072mol / L CaCl 2 In the aqueous solution, stir evenly and fully, and adjust the pH to 6.0 to obtain solution A; take 117.5mL of 0.63g / L sodium alginate solution, adjust the pH to 6.0, then slowly add solution A dropwise, and keep stirring throughout the process to make it fully reacted. After the solution A is added, the stirring is continued for 30-60 minutes to obtain the core-shell structure collagen polypeptide chelated calcium nanoparticles with a particle diameter ranging from 400-1000 nm.

Embodiment 3

[0025] Take 15ml of 0.05g / ml collagen peptide chelated calcium aqueous solution and slowly add to 10ml of 0.020mol / L BaCl 2 In the aqueous solution, stir evenly and fully, adjust the pH to 7.5 to obtain solution A; take 117.5mL of 1.0g / L sodium alginate solution, adjust the pH to 7.5, then slowly add solution A dropwise, and keep stirring throughout the process to make it fully reacted. After the solution A is added, the stirring is continued for 30-60 minutes to obtain the core-shell structure collagen polypeptide chelated calcium nanoparticles with a particle size ranging from 200-800 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com