Purification method of electronic-grade methyl phenyl diethoxy silane

A technology of methylphenyldiethoxysilane and purification method, which is applied in chemical instruments and methods, silicon organic compounds, compounds of group 4/14 elements of the periodic table, etc., and can solve problems such as the influence of integrated circuit material manufacturing , to achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1 ton of methylphenyldiethoxysilane with a content of 99% (weight) enters the desolventization tower of the electronic grade silane refining system through a silane compressor, and the number of theoretical plates is 60. The desolventization tower adopts normal pressure operation, and the temperature at the bottom of the tower is Heating by temperature programming, gradually heating from room temperature to 100 °C. The temperature of the distillate received at the top of the tower was 66°C, which was detected as the separated solvent tetrahydrofuran. When the amount of distillate is getting smaller and smaller until it does not come out, the temperature at the top of the tower begins to rise, and the bottom of the tower has no solvent.

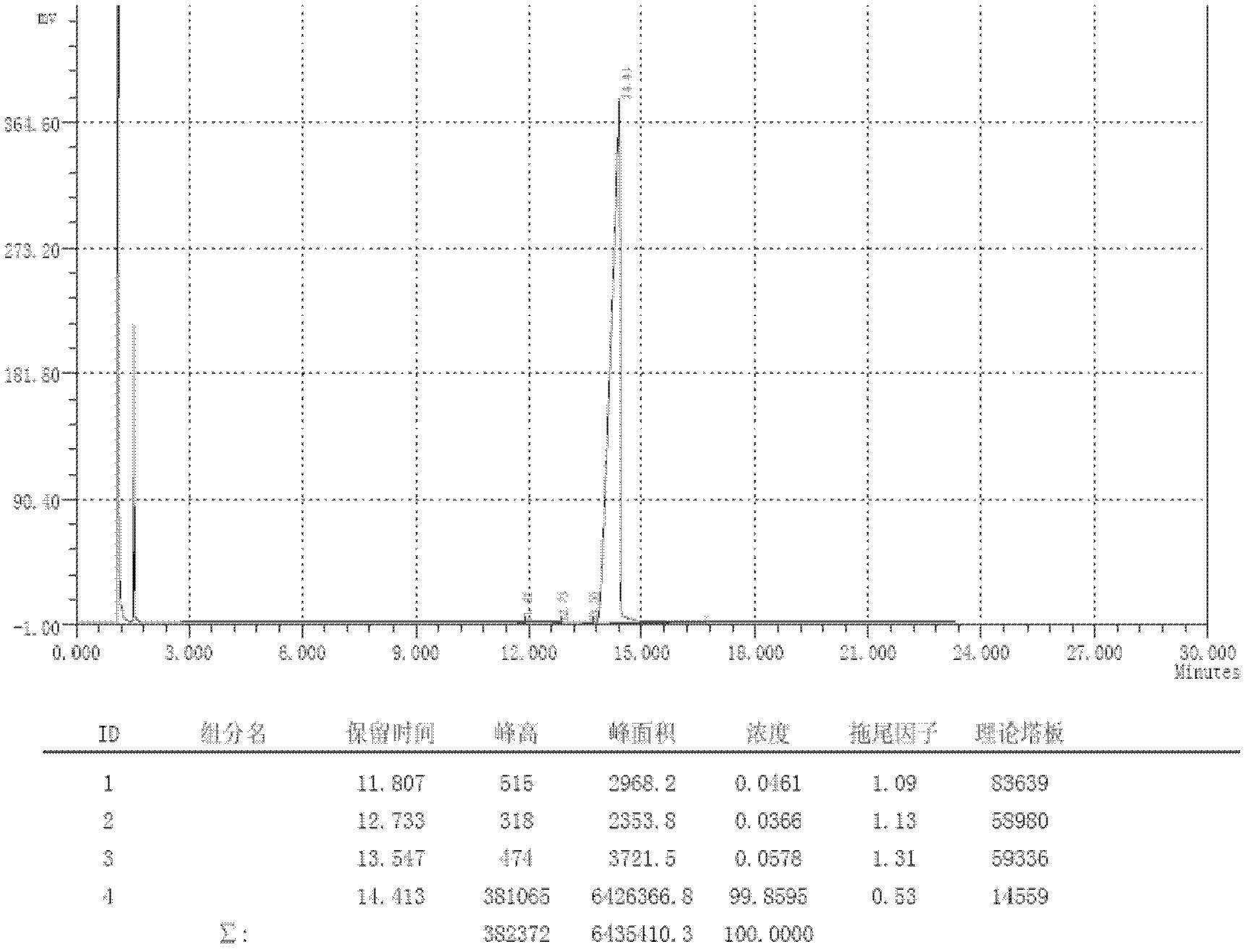

[0019] The methylphenyldiethoxysilane that has been desolventized flows into the deheavy rectification tower from the bottom of the tower, and the desolventization tower restarts the next batch of rectification. The weight-removing rec...

Embodiment 2

[0022] The solvent removal tower and the weight removal rectification tower are the same as in Example 1.

[0023] The methylphenyldiethoxysilane with 99% content (weight) enters the desolventization tower of the electronic-grade silane refining system through a silane compressor. Heat to 100°C. The temperature of the distillate received at the top of the tower was 66°C, which was detected as the separated solvent tetrahydrofuran. When the amount of distillate is getting smaller and smaller until it does not come out, the temperature at the top of the tower begins to rise, and the bottom of the tower has no solvent.

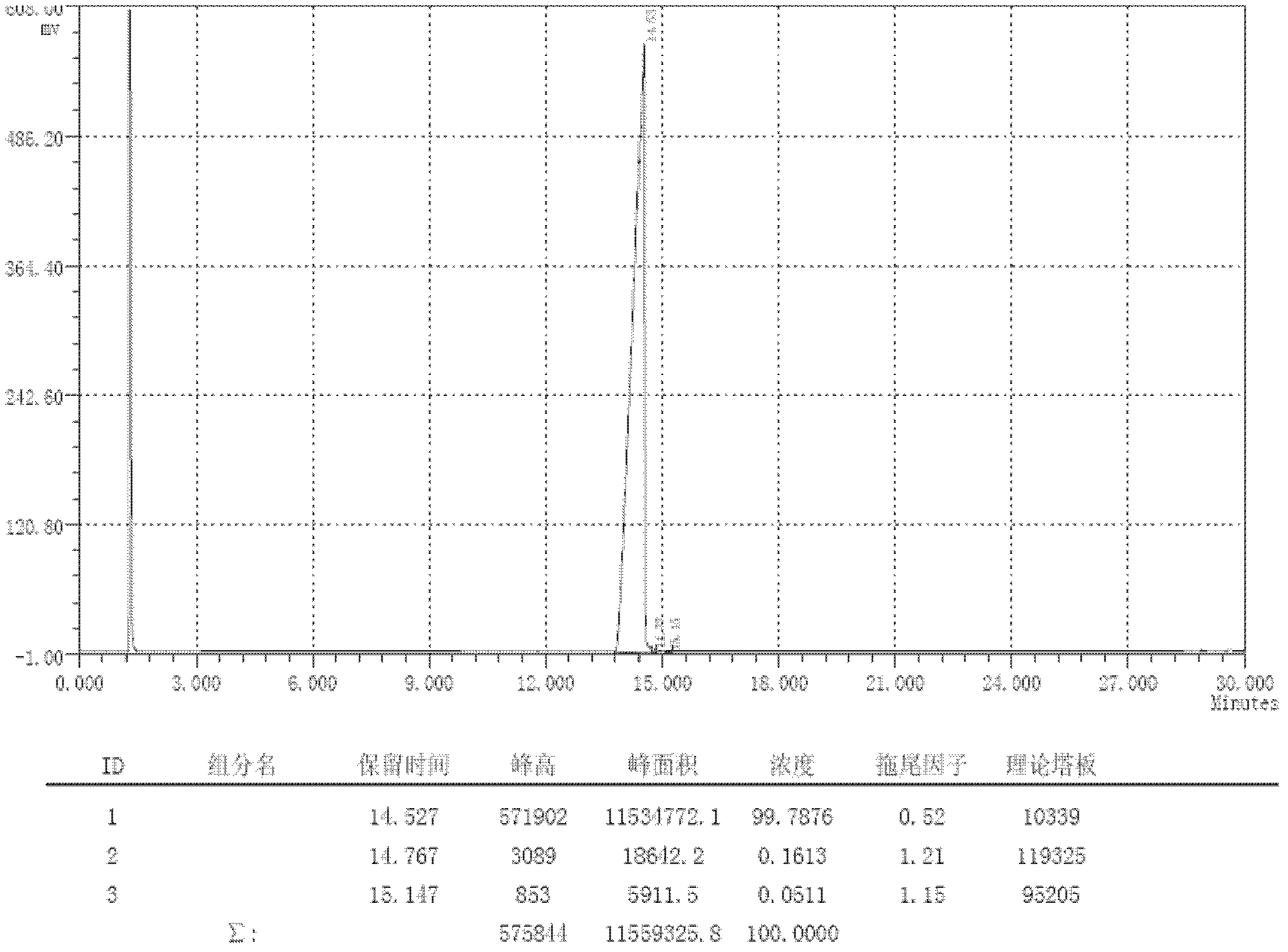

[0024] The methylphenyldiethoxysilane that has been desolventized flows into the deheavy rectification tower from the bottom of the tower, and the desolventization tower restarts the next batch of rectification. The weight-removing rectification tower is operated under reduced pressure, and the vacuum degree is maintained at 31mmHg. The bottom of the tower is ...

Embodiment 3

[0027] The solvent removal tower and the weight removal rectification tower are the same as in Example 1.

[0028] The methylphenyldiethoxysilane with 99% content (weight) enters the desolventization tower of the electronic-grade silane refining system through a silane compressor. Heat to 100°C. The temperature of the distillate received at the top of the tower was 66°C, which was detected as the separated solvent tetrahydrofuran. When the amount of distillate is getting smaller and smaller until it does not come out, the temperature at the top of the tower begins to rise, and the bottom of the tower has no solvent.

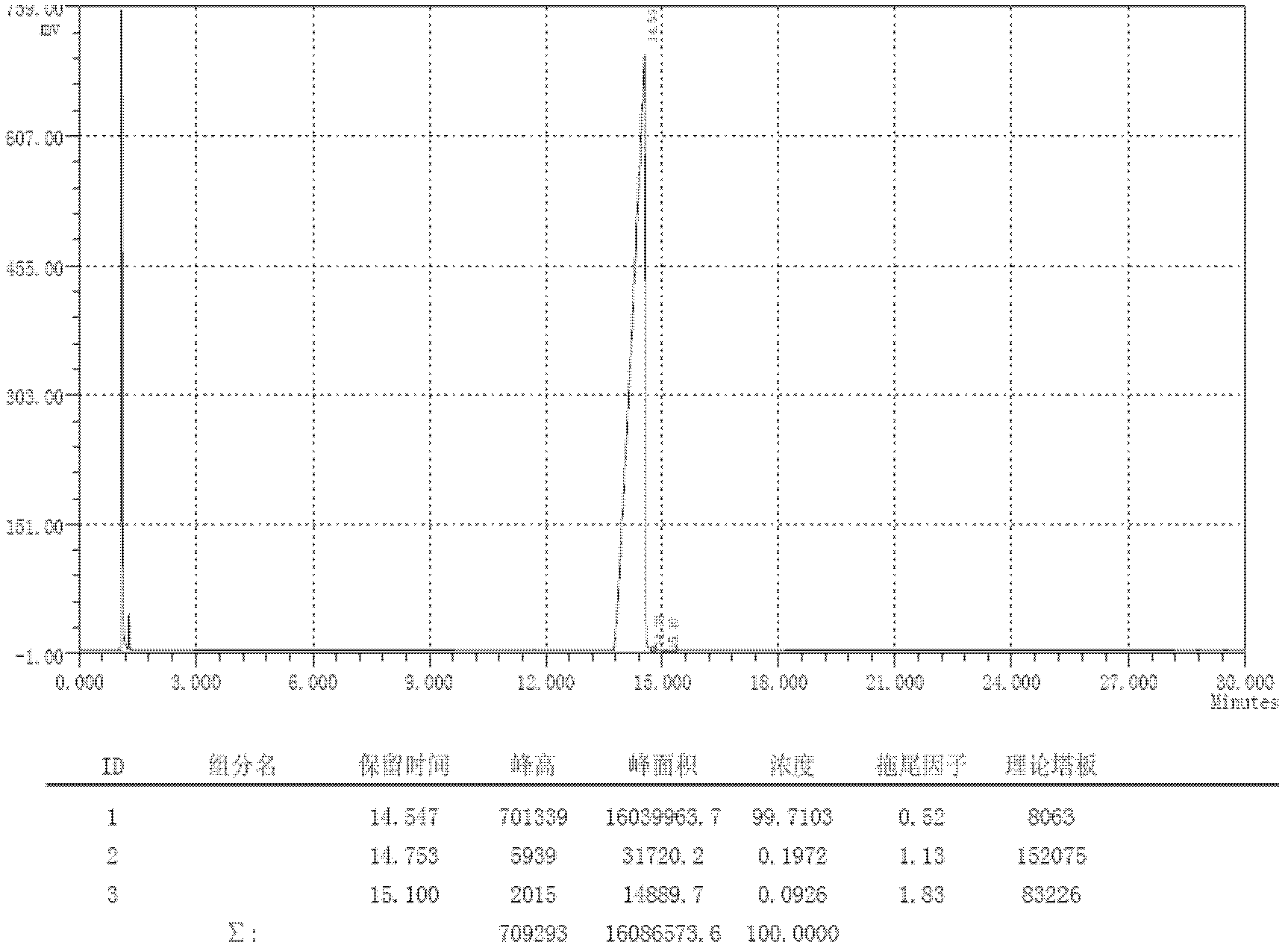

[0029] The methylphenyldiethoxysilane that has been desolventized flows into the deheavy rectification tower from the bottom of the tower, and the desolventization tower restarts the next batch of rectification. The weight-removing rectification tower is operated under reduced pressure, and the vacuum degree is maintained at 31mmHg. The bottom of the tower is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com