Method for preparing low-sodium carnallite, sodium chloride and magnesium chloride from refined magnesium slag

A technology for refining magnesium and carnallite, applied in the direction of improving process efficiency, etc., can solve problems such as difficult implementation, large amount of waste residue, complicated process, etc., and achieve the effects of environmental friendliness, high-efficiency utilization, and reasonable process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

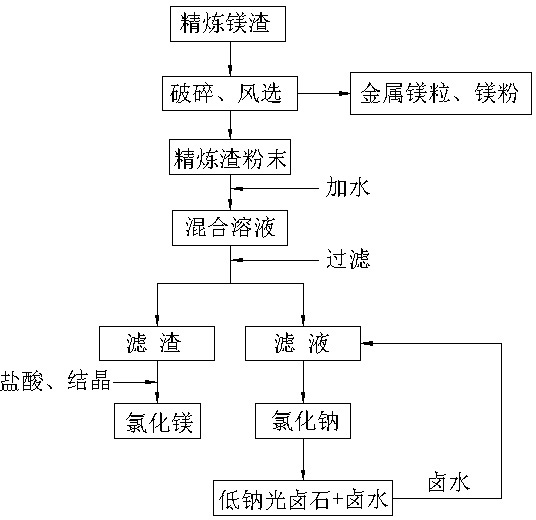

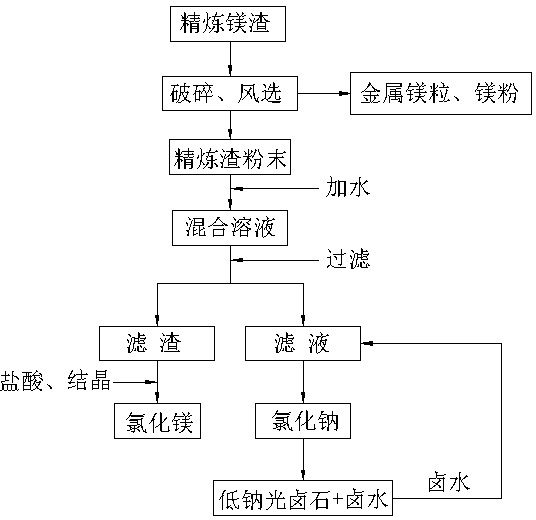

[0030] like figure 1 Shown process route, its process step is:

[0031] 1) Crushing and screening: crush the refined magnesium slag to more than 60 meshes, and screen the metal magnesium particles through winnowing;

[0032] 2) Dissolution: Add the refined magnesium slag powder after winnowing into a reaction kettle with a stirring and heating device, add water, heat, stir and mix to obtain a mixed solution of soluble salt and insoluble matter; the mass of refined magnesium slag and water The ratio is 1:2—3, the heating temperature is 135±5°C, and the stirring speed is 20 r / min; according to the condition of the material, the stirring speed can be adjusted between 20-40 r / min;

[0033] 3) Filtration: filter the mixed solution obtained in step 2) to obtain filtrate and filter residue ;

[0034] 4) Keep the temperature of the filtrate at about 80°C, and adjust the K in the filtrate with magnesium chloride solution + with Mg 2+ The molar ratio is 1:1.2;

[0035] 5) The filt...

Embodiment 2

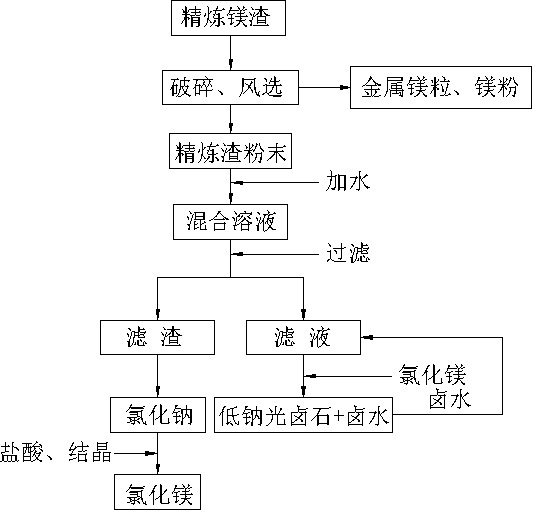

[0040] like figure 2 Shown process route, its process step is:

[0041] A method for producing low-sodium carnallite, sodium chloride, and magnesium chloride from refined magnesium slag, the method comprising the following steps:

[0042] 1) Crushing and screening: crush the refined magnesium slag to more than 60 meshes, and screen the metal magnesium particles through winnowing;

[0043] 2) Dissolution: Add the refined magnesium slag powder after winnowing into a reaction kettle with a stirring and heating device, add water, heat, stir and mix to obtain a mixed solution of soluble salt and insoluble matter; the mass of refined magnesium slag and water The ratio is 1:2—3, the heating temperature is 135±5°C, and the stirring speed is 20r / min; according to the condition of the material, the stirring speed can be adjusted between 20-40 r / min;

[0044] 3) Filtration: filter the mixed solution obtained in step 2) to obtain filtrate and filter residue ;

[0045] 4) Keep the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com