Vibrato-drilling type punching drilling rig

A vibration mechanism and drilling rig technology, applied in mechanically driven excavators/dredgers, vibration generating devices, earth movers/shovels, etc., can solve the problem of increasing construction costs, high center of gravity of drilling rigs, affecting work efficiency and project progress and other problems, to achieve the effect of reducing equipment cost, convenient moving and transportation, and reducing the height of the mast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

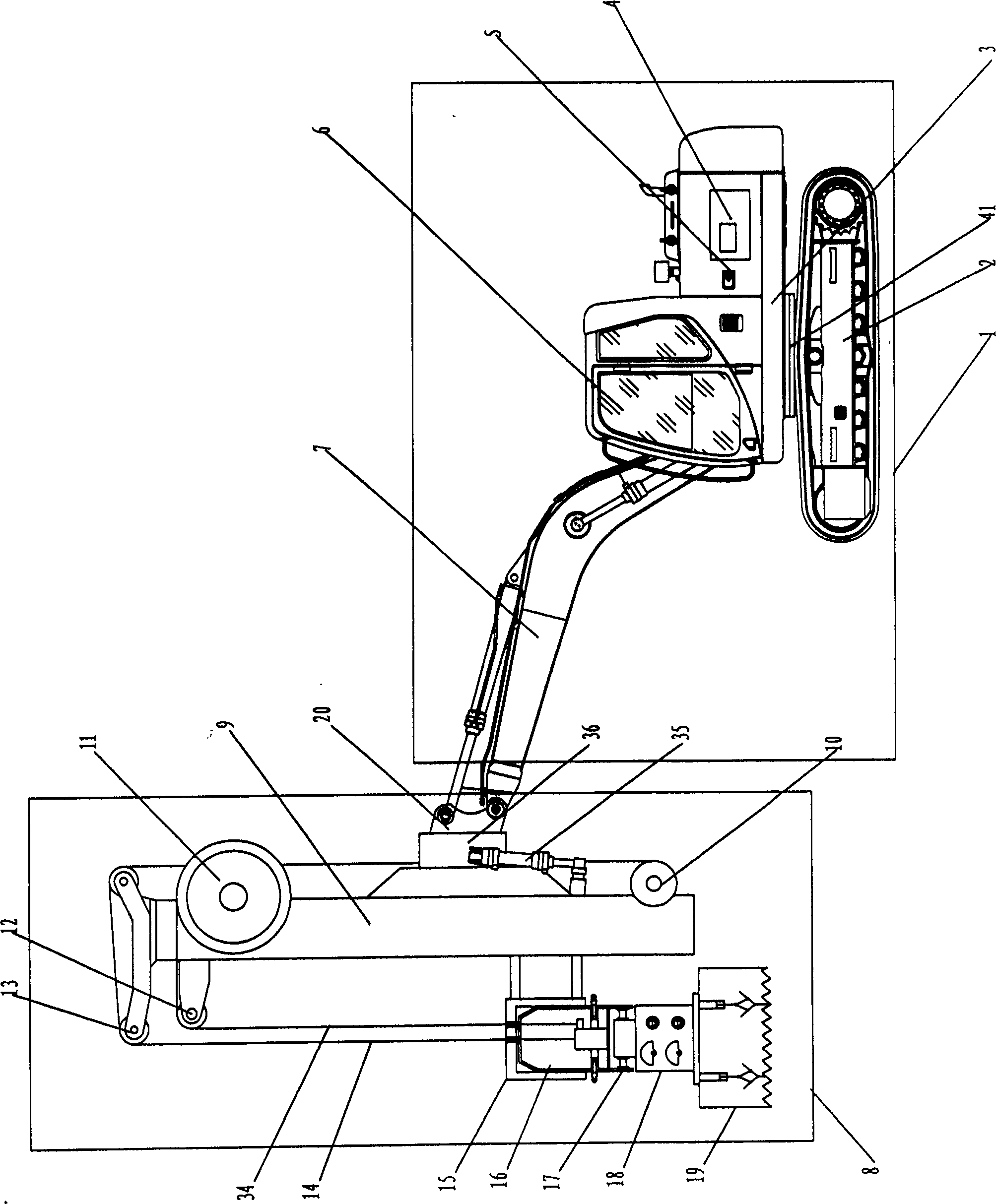

[0025] Such as Figure 1 and Figure II As shown, the vibratory drilling rig of the present invention is composed of a chassis mechanism 1 and a working device 8; The cab 6, the engine 4, the hydraulic system 5 and the boom 7 controlled by the hydraulic system 5 are composed. Chassis mechanism 1 also can adopt crawler or wheel type hydraulic excavator.

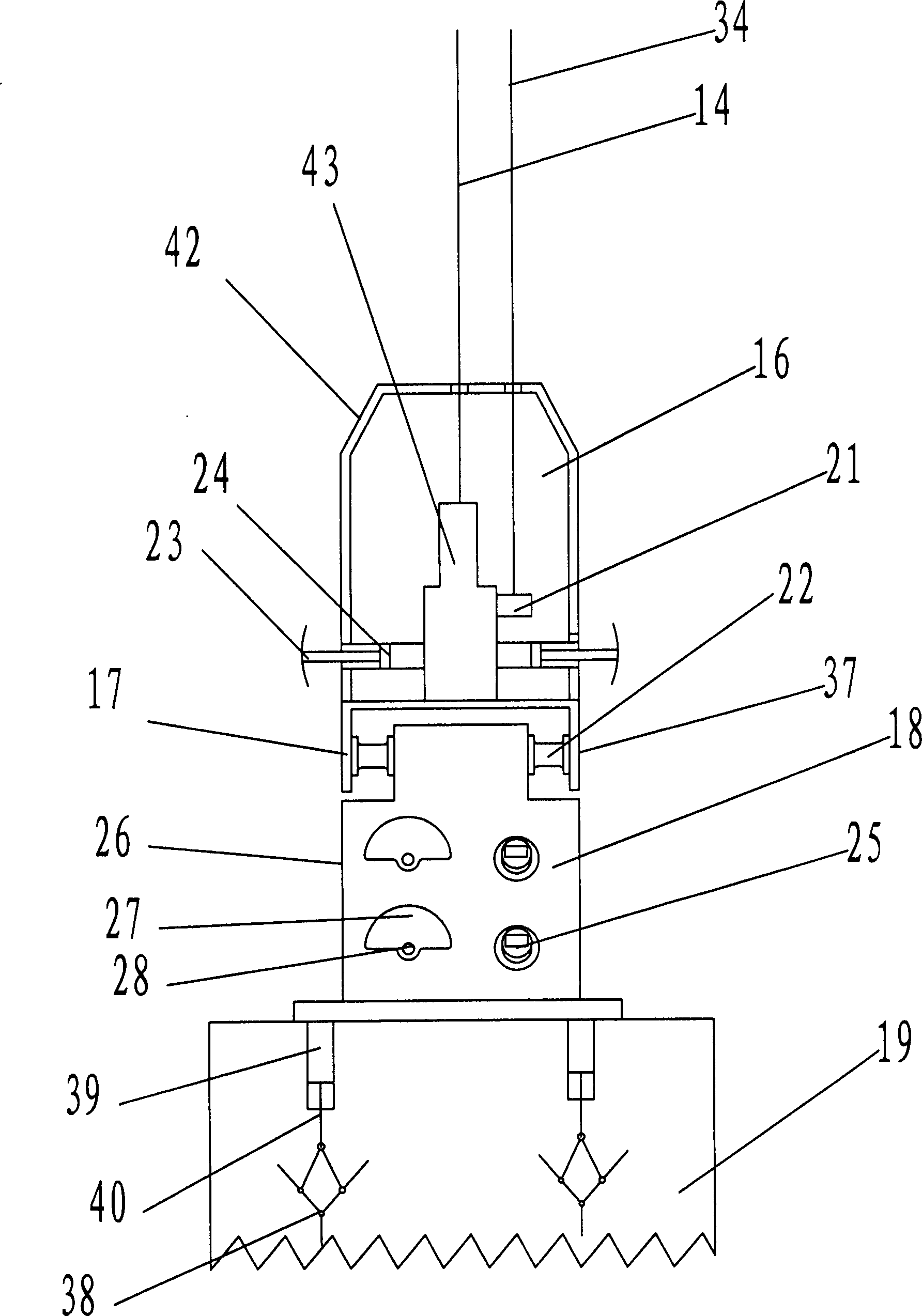

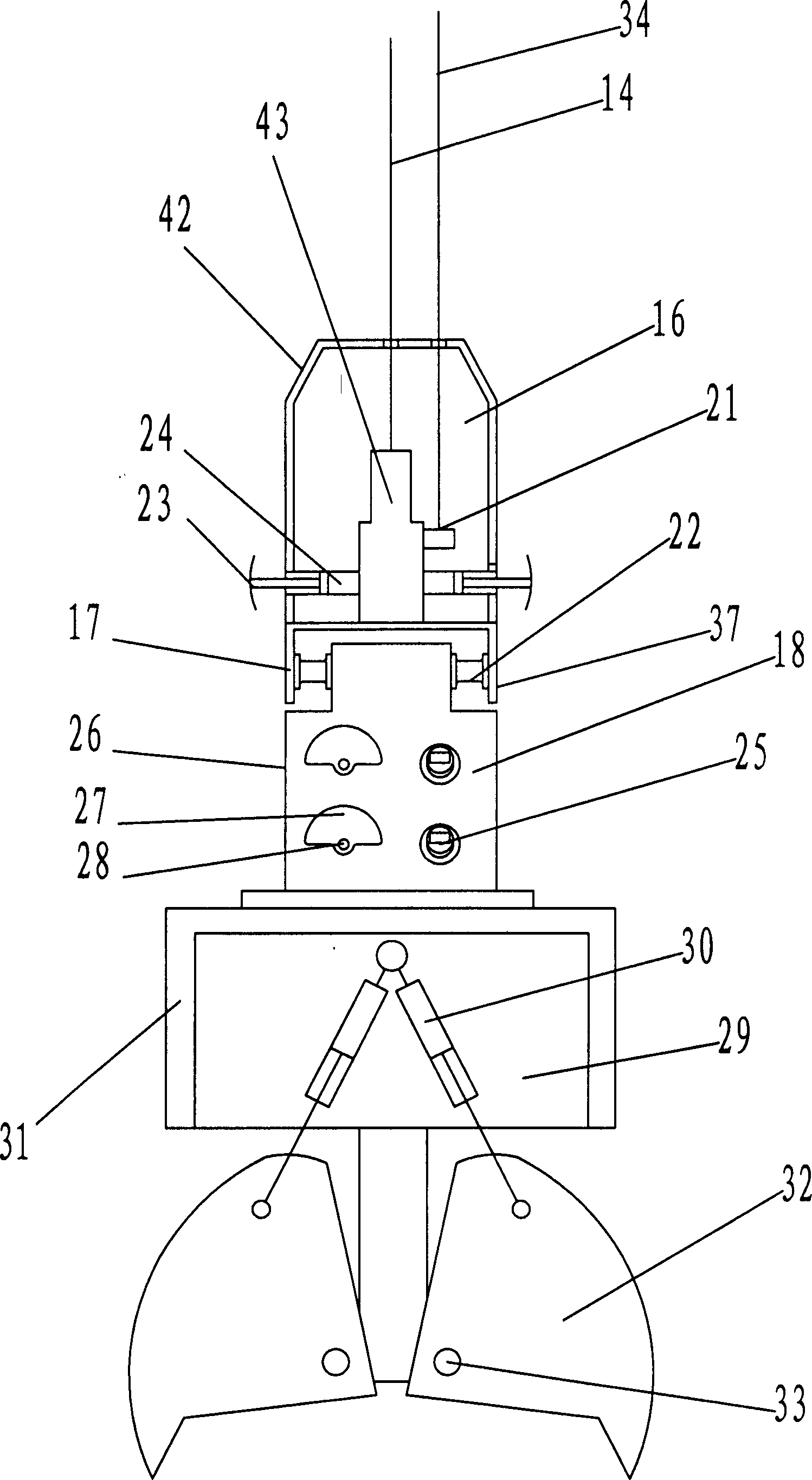

[0026] Working device 8 is mainly made of mast mechanism 9, vibrating mechanism 18, damping mechanism 17, guiding mechanism 16 and earth-borrowing bucket 19, and mast mechanism 9 is connected with the big arm 7 of chassis mechanism 1 through connecting seat 20, and connecting seat 20 is provided with There is a slewing bearing 36, and the mast mechanism 9 is connected with the slewing bearing 36. The middle part of the mast mechanism 9 and the slewing bearing 36 are connected with an angle adjustment oil cylinder 35 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com