Fiber composite core rod with improved performances for overhead wire and preparation method thereof

A fiber composite mandrel and overhead wire technology, which is applied in the direction of cable/conductor manufacturing, power cables, electrical components, etc., can solve the problems of poor interface of composite materials, limited source of materials, low heat resistance, etc., and achieve high temperature resistance Excellent, excellent heat and heat aging, low manufacturing cost effect

Active Publication Date: 2012-04-25

SHENZHEN YONGGUI TECH CO LTD

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] The technical problem to be solved by the present invention is to overcome the defects of the existing carbon fiber composite mandrels, such as high cost, limited source of materials, low heat resistance, and poor interface of composite materials, and provide a low manufacturing cost, high cost performance, Composite mandrel with excellent mechanical, thermal and heat aging, creep properties and preparation method thereof

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

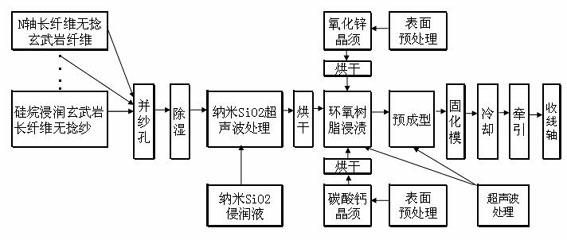

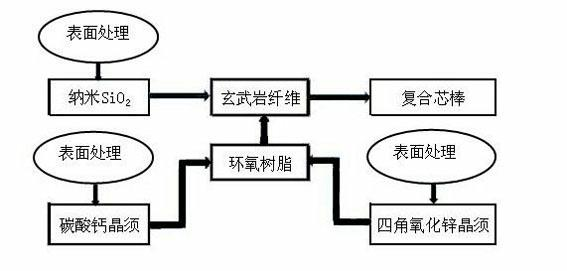

The invention relates to a fiber composite core rod with improved performances for an overhead wire, comprising continuous basalt fiber twistless roving and an epoxy resin part, wherein the epoxy resin part is formed at the periphery of the continuous basalt fiber twistless roving by uniform dipping;The composite core rod is prepared by the following steps of: (1) using a coupling agent to carry out surface treatment on nano SiO2; (2) preparing infiltrate of the nano SiO2, and using the infiltrate of the nano SiO2 to carry out surface roughening and lipophilicity modification and treatment onthe continuous basalt fiber twistless roving; (3) using the coupling agent to carry out surface treatment on calcium carbonate whiskers and square zinc oxide whiskers; (4) preparing epoxy resin dipping solution and conveying the continuous basalt fiber twistless roving into the epoxy resin dipping solution for full dipping; and (5) treating the continuous basalt fiber twistless roving by adoptinga pulling-extruding process. The fiber composite core rod has the advantages of low manufacturing cost, higher cost performance, and excellent mechanization, heating and heat ageing resistance and creepage performances.

Description

technical field [0001] The invention relates to a fiber composite mandrel for overhead wires for power transmission, in particular to a composite mandrel with low manufacturing cost, high cost performance, excellent mechanical, thermal and thermal aging and creep properties and its preparation method. Background technique [0002] Overhead conductors are also called expansion conductors. The existing overhead wire is a carbon fiber composite core overhead wire, and its structure is: the center is a carbon fiber composite mandrel, and the periphery is a trapezoidal soft aluminum wire concentrically twisted with the carbon fiber composite mandrel. The cross section of the carbon fiber composite mandrel is circular, and the longitudinal direction is a uniform round rod structure. The carbon fiber composite mandrel is divided into a carbon fiber composite mandrel with a two-layer structure and a carbon fiber composite mandrel with a three-layer structure. The carbon fiber...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B9/00H01B13/00

Inventor 颜明赵燕代金涛刘连元闻期洋吴永然郑京红邓任作刘军曾永民卢供华唐桥梁王硕峰刘辉申芝兰

Owner SHENZHEN YONGGUI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com