Circuit structure for reading orthogonal rotating current of Hall sensor

A Hall sensor and circuit structure technology, applied in logic circuits, electrical components, reliability improvement and modification, etc., can solve problems such as sensor signal interference, offset voltage cancellation, amplifier offset and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

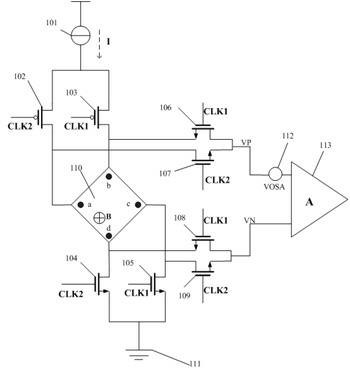

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

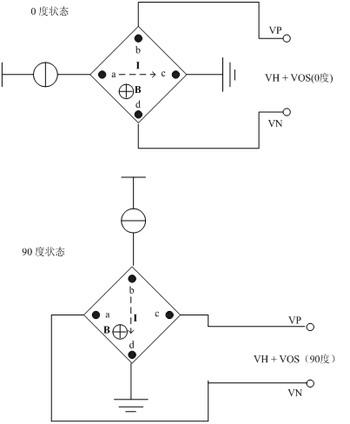

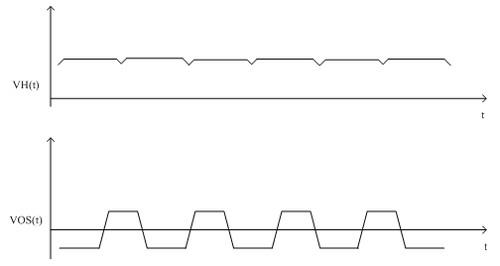

[0011] Such as image 3 As shown, a circuit structure for reading out the orthogonal rotating current of the Hall sensor includes a constant current source 101, two PMOS switches (102, 103), six NMOS switches (104, 105, 106, 107, 108 , 109), an amplifier 113 and a regular quadrilateral Hall plate 110, and grounds 111, 112 are the equivalent input offset and noise sources of the amplifier 113 (defined as VOSA). The eight MOS switches need to provide two-phase non-overlapping clocks to perform switch selection operations. The regular quadrilateral Hall plate 110 leads to a terminal at its four corners respectively, and two PMOS switches (102, 103) and two NMOS switches (104, 105 ), the constant current source 101 is connected to the other end of the two PMOS switches (102, 103), and the current is injected into the regular quadrilateral Hall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com