Method and device for carrying out online component detection and solidification structure control on magnesium alloy

A solidification structure and composition detection technology, which is applied in the field of control, magnesium alloy large ingot and complex casting forming process, magnesium alloy on-line composition detection and solidification structure control of furnace melt inspection, alloy preparation process detection field, can solve the problem It is unfavorable to analyze and test the problems such as the deployment of the work site, so as to facilitate the production guidance, reduce the production cost, and achieve the effect of stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

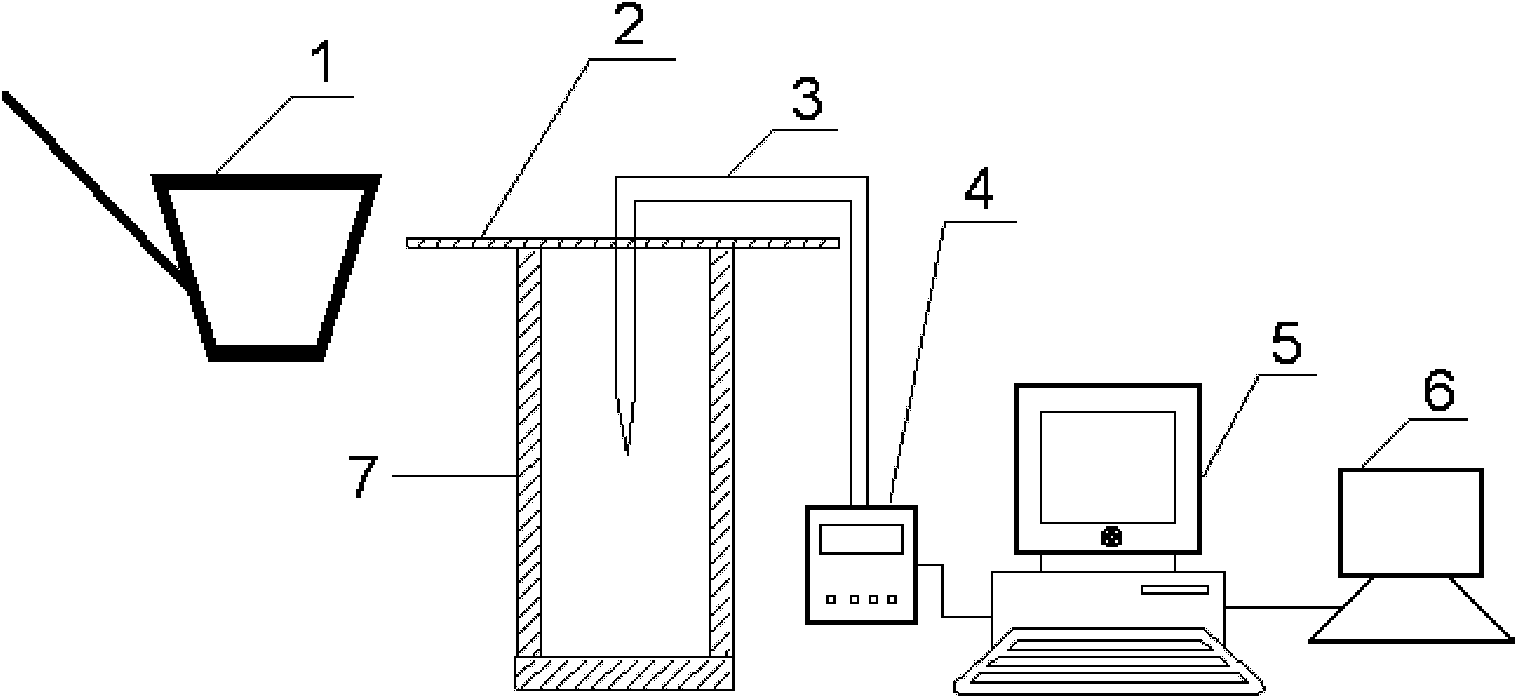

[0047] use figure 1 The shown process flow and equipment are used to smelt magnesium alloy of alloy grade WE43, and the basic operation steps are as follows:

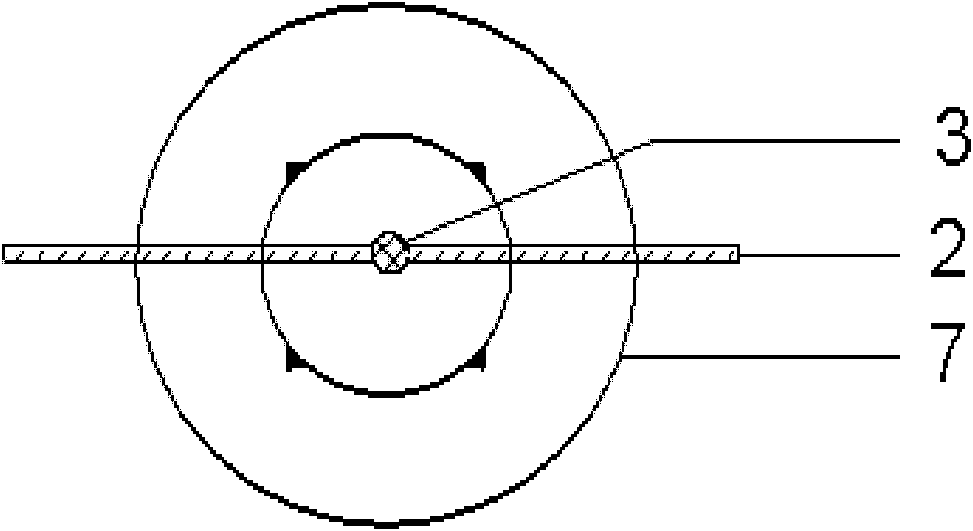

[0048] 1. Use a 40Kg crucible resistance furnace to melt the WE43 magnesium alloy, raise the temperature of the melt to 760°C, and fix the probe of the thermocouple 3 to a specific position of the constant volume mold 7 through the positioning fixture 2.

[0049] 2. Turn on the temperature acquisition system 4, take out the magnesium liquid from the crucible by using the quantitative pouring ladle 1, and quickly pour it into the constant volume mold 7.

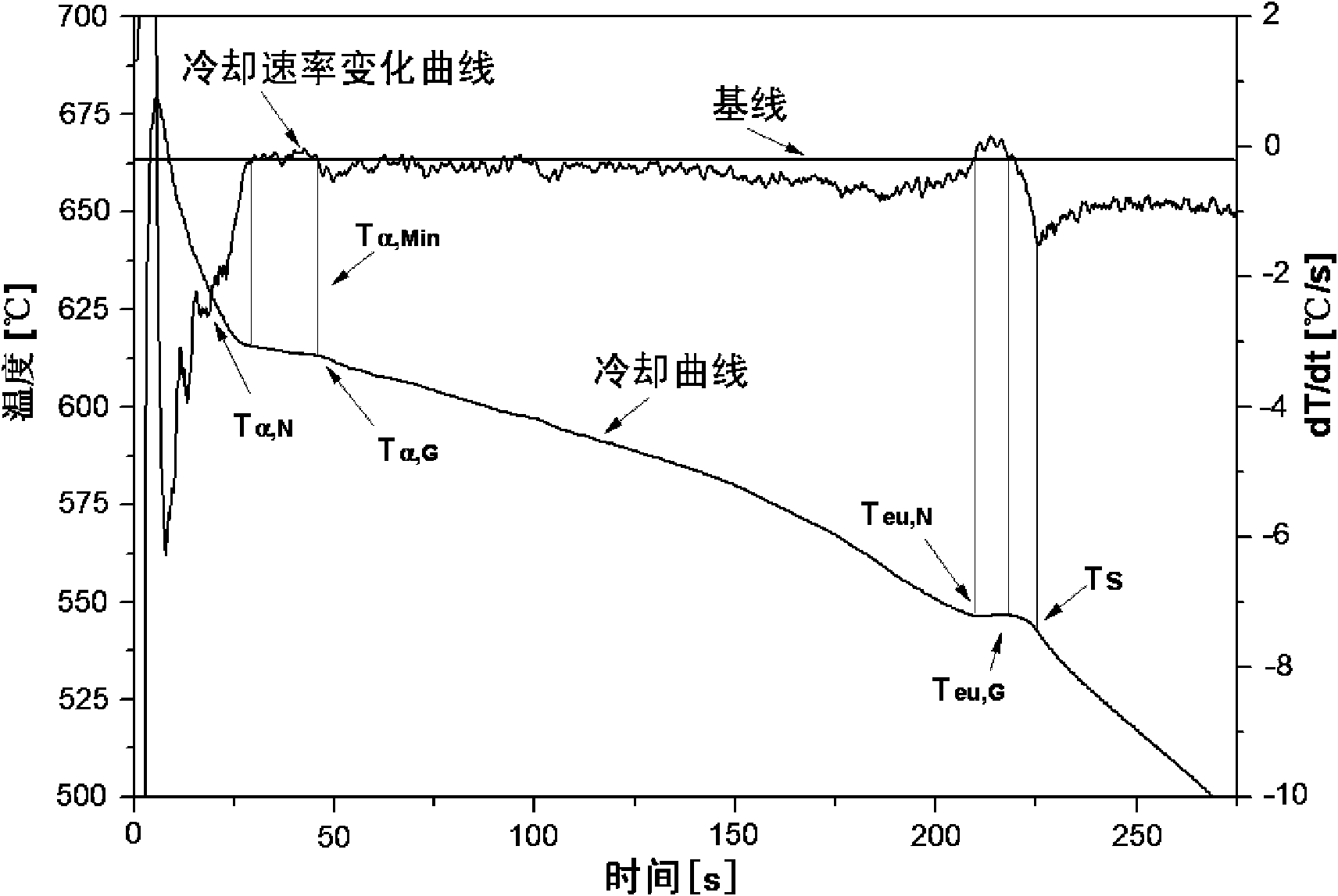

[0050] 3. The T of the magnesium alloy melt is measured by the magnesium alloy online composition detection and solidification structure control device. α-n实 , T eu-n实 , T eu-g实 , T s实 and the corresponding t α-n实 , t eu-n实 , t eu-g实 , t s实 Calibrate.

[0051] 4. Call the standard T in the cast magnesium alloy database 6 α-n标 , T eu-n标 , T eu-g标 , T s标 , t ...

Embodiment 2

[0054] use figure 1 The shown process flow and equipment are used to smelt the magnesium alloy of alloy grade AZ31, and the basic operation steps are as follows:

[0055] 1. Use a 4Kg crucible resistance furnace to melt the AZ31 magnesium alloy, raise the temperature of the melt to 740°C, and fix the probe of the thermocouple 3 to a specific position of the constant volume mold 7 through the positioning fixture 2.

[0056] 2. Turn on the temperature acquisition system 4, take out the magnesium liquid from the crucible using the quantitative ladle 1, measure the temperature through the thermocouple 3, and pour it into the constant volume mold 7 when it drops to 720°C.

[0057] 3. The T of the magnesium alloy melt is measured by the magnesium alloy online composition detection and solidification structure control device. α-n实 , T eu-n实 , T eu-g实 , T s实 and the corresponding t α-n实 , t eu-n实 , t eu-g实 , t s实 Calibrate.

[0058] 4. Call the standard T in the cast magnesiu...

Embodiment 3

[0061] use figure 1 The shown process flow and equipment are used to smelt the magnesium alloy of alloy grade WE54, and the basic operation steps are as follows:

[0062] 1. Use a 200Kg crucible resistance furnace to melt the WE54 magnesium alloy, raise the temperature of the melt to 780°C, and fix the probe of the thermocouple 3 to a specific position of the constant volume mold 7 through the positioning fixture 2.

[0063] 2. Turn on the temperature acquisition system 4, take out the magnesium liquid from the crucible using the quantitative ladle 1, measure the temperature through the thermocouple 3, and pour it into the constant volume mold 7 when it drops to 760°C.

[0064] 3. The T of the magnesium alloy melt is measured by the magnesium alloy online composition detection and solidification structure control device. α-n实 , T eu-n实 , T eu-g实 , T s实 and the corresponding t α-n实 , t eu-n实 , t eu-g实 , t s实 Calibrate.

[0065] 4. Call the standard T in the cast magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com