Preparation method of waterborne polyurethane-polyacrylic ester composite emulsion

A water-based polyurethane and polyacrylate technology, applied in the field of polymer and/or material synthesis, can solve problems such as insufficient water solubility, inability to form films, affecting ink adhesion and wet rub resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

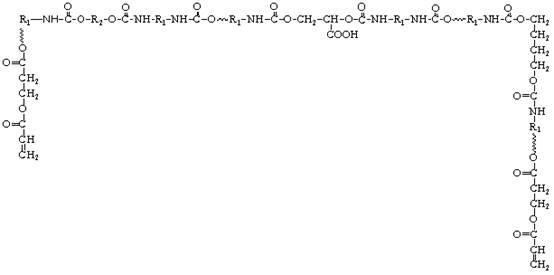

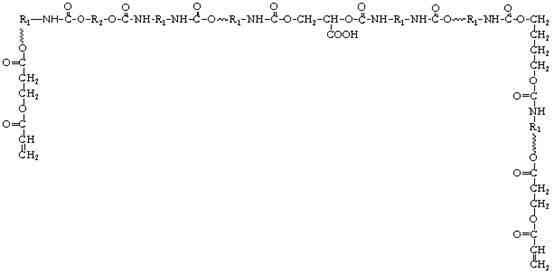

Method used

Image

Examples

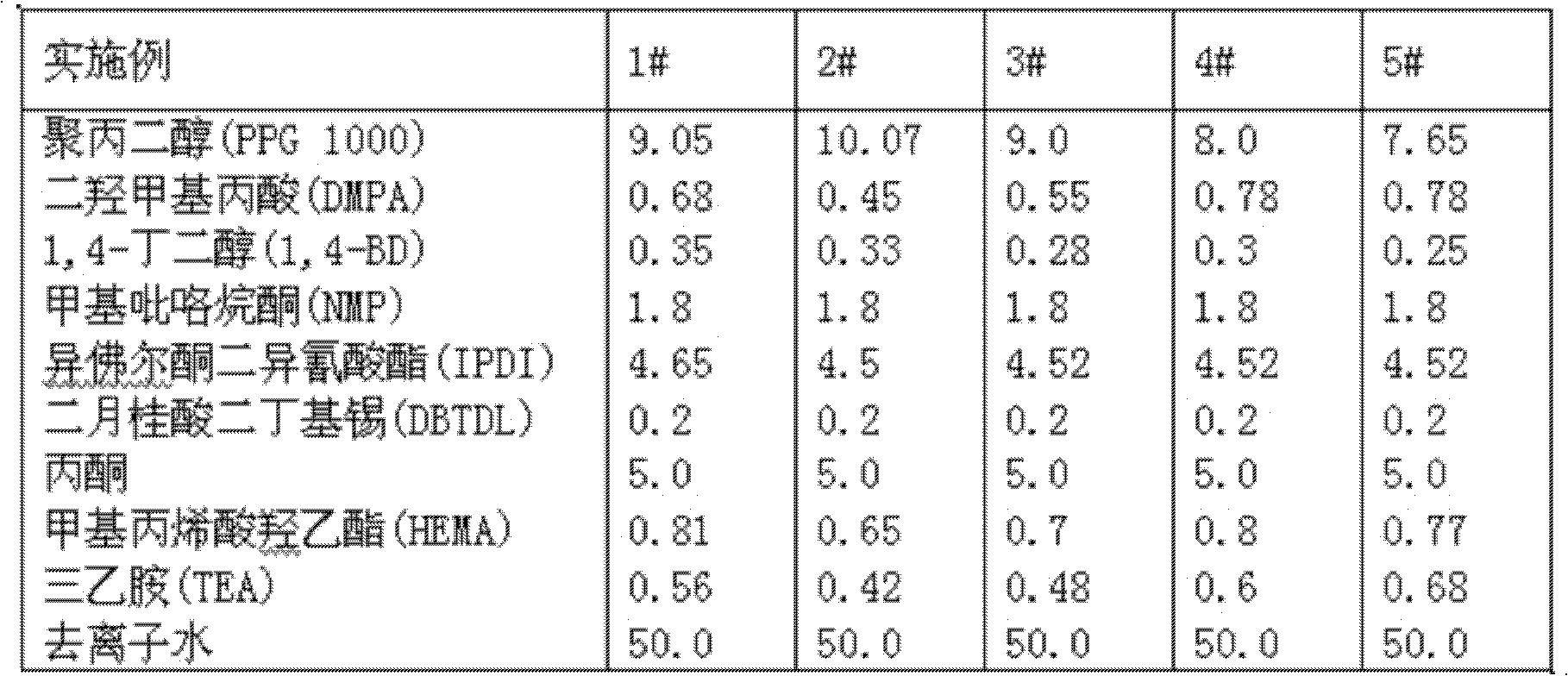

Embodiment 1

[0057] Example 1: The typical synthesis of vinyl-terminated waterborne polyurethane (VLWPU) was carried out in a 250 mL four-neck flask equipped with a thermometer, a mechanical stirrer and a condenser tube (with a drying tube connected to the top).

[0058] first at room temperature PPG 1000 (9.05 g), DMPA (0.68 g) and 1,4- BD (0.35 g) was added to the flask. then join NMP (1.8 g) was stirred until a homogeneous system was obtained. Raise the temperature to 60-90°C, then add dropwise within 30-60 min IPDI (4.65 g), DBTDL (3-5 drops) and acetone (5.0 g) mixed solution, continue to react for 3-5 h, to obtain isocyanate-terminated polyurethane prepolymer ( NCO-PU ). add to it HEMA (0.81 g), maintain the reaction at 60-80°C and continue the reaction for 1.5-2.5 h to obtain vinyl-terminated polyurethane ( VLPU ). Then cool down to 30-50°C, use TEA (0.56 g) neutralized VLPU , the reaction was completed within 15-30 min. Finally, slowly add distilled water (5...

Embodiment 2

[0060] Example 2 : put at room temperature PPG 1000 (10.07 g), DMPA (0.45 g) and 1,4- BD (0.33 g) was added to the flask. then join NMP (1.8g) was stirred until a homogeneous system was obtained. At this time, raise the temperature to 60-90°C, and then add it dropwise within 30-60 minutes IPDI (4.5 g), DBTDL (3-5 drops) and acetone (5.0 g), the reaction was carried out under the condition of stirring in an oil bath for 3-5 h to obtain an isocyanate-terminated polyurethane prepolymer ( NCO-PU ). At this time, join HEMA (0.65 g), and the reaction was continued at 60-80°C for 1.5-2.5 h to obtain vinyl-terminated polyurethane ( VLPU ). Secondly, at 30-50 °C, use TEA (0.42 g) neutralized VLPU , the reaction was completed within 15-30 min. Finally, distilled water (50 g) was slowly added to the neutralized polyurethane, and dispersed at room temperature for 30–60 min at high speed to obtain vinyl-terminated waterborne polyurethane with a carboxyl content of ...

Embodiment 3

[0061] Example 3 : at room temperature PPG 1000 (9g), DMPA (0.55 g) and 1,4- BD (0.28g) was added to the flask. then join NMP (1.8g) was stirred until a homogeneous system was obtained. At this time, raise the temperature to 60-90°C, and then add it dropwise within 30-60 minutes IPDI (4.52 g), DBTDL (3-5 drops) and acetone (5.0 g), the reaction was carried out under the condition of stirring in an oil bath for 3-5 h to obtain an isocyanate-terminated polyurethane prepolymer ( NCO-PU ). At this time, join HEMA (0.7 g), and the reaction was continued at 60-80 °C for 1.5-2.5 h to obtain vinyl-terminated polyurethane ( VLPU ). Secondly, at 30-50°C, use TEA (0.48 g) neutralized VLPU , the reaction was completed within 15-30 min. Finally, slowly add distilled water (50 g) to the neutralized polyurethane, and disperse at a high speed for 30-60 min at room temperature to obtain a vinyl-terminated waterborne polyurethane with a carboxyl group content of 4% ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Initial thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com