Color master batches used by polyvinylidene fluoride OK cable product and preparation method of color master batches

A polyvinylidene fluoride and color masterbatch technology is applied in the field of color masterbatch and color masterbatch preparation, which can solve the problems of static electricity, easy migration of pigments, and unstable performance, so as to prevent the generation of electrostatic charges, resist the High electrostatic performance and the effect of preventing dust adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

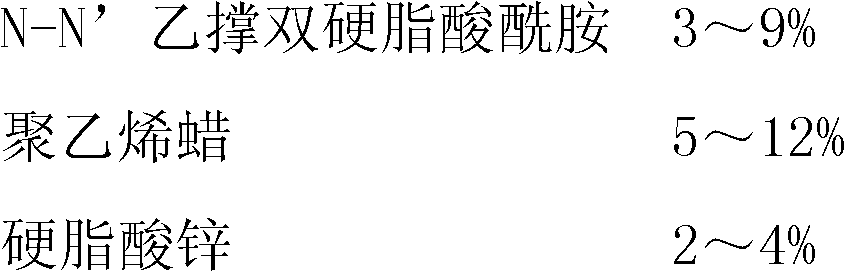

[0017] Color masterbatch used to prepare red polyvinylidene fluoride OK line products:

[0018] First weigh the materials according to the following proportions for pre-mixing:

[0019]

[0020] The above units are g.

[0021] Then put the above-mentioned mixture in a kneading pot with a current control of 35A and mix it at high speed until it is coated, and then put the uniformly stirred mixture into a twin-screw extruder whose main machine temperature is controlled at about 200°C to extrude. After cooling, Dried and granulated to make the required masterbatch.

Embodiment 2

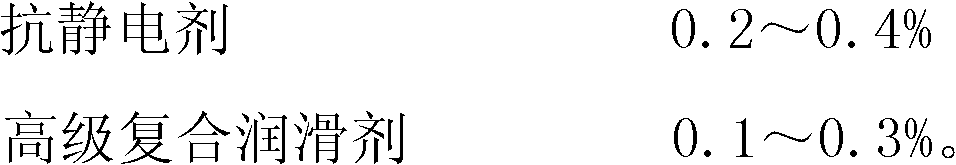

[0023] Color masterbatch used to prepare red polyvinylidene fluoride OK line products:

[0024] First weigh the materials according to the following proportions for pre-mixing:

[0025]

[0026] The above units are g.

[0027] Then put the above-mentioned mixture in a kneading pot with a current control of 35A and mix it at a high speed until it is coated, and then put the uniformly stirred mixture into a twin-screw extruder whose main machine temperature is controlled at about 210°C to extrude. After cooling, Dried and granulated to make the required masterbatch.

Embodiment 3

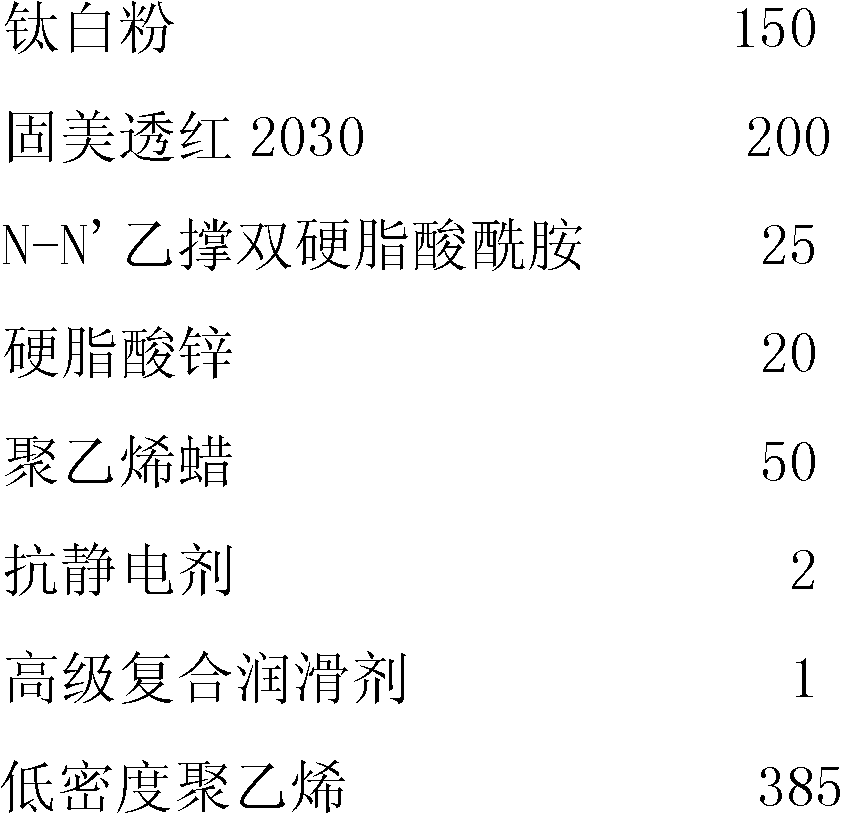

[0029] Color masterbatch used to prepare blue polyvinylidene fluoride OK line products:

[0030] First weigh the materials according to the following proportions for pre-mixing:

[0031]

[0032]

[0033] The above units are g.

[0034] Then put the above-mentioned mixture in a kneading pot with a current control of 35A and mix it at high speed until it is coated, and then put the uniformly stirred mixture into a twin-screw extruder whose main machine temperature is controlled at about 200°C to extrude. After cooling, Dried and granulated to make the required masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com