Measuring apparatus of micro electronic mechanical system (MEMS) two-dimension (2d) scanning mirror scanning angle

A technology of a two-dimensional scanning mirror and a micromechanical system is applied in the field of measuring devices for the scanning angle of a two-dimensional scanning mirror. Realization and subsequent improvement, simple structure, strong real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

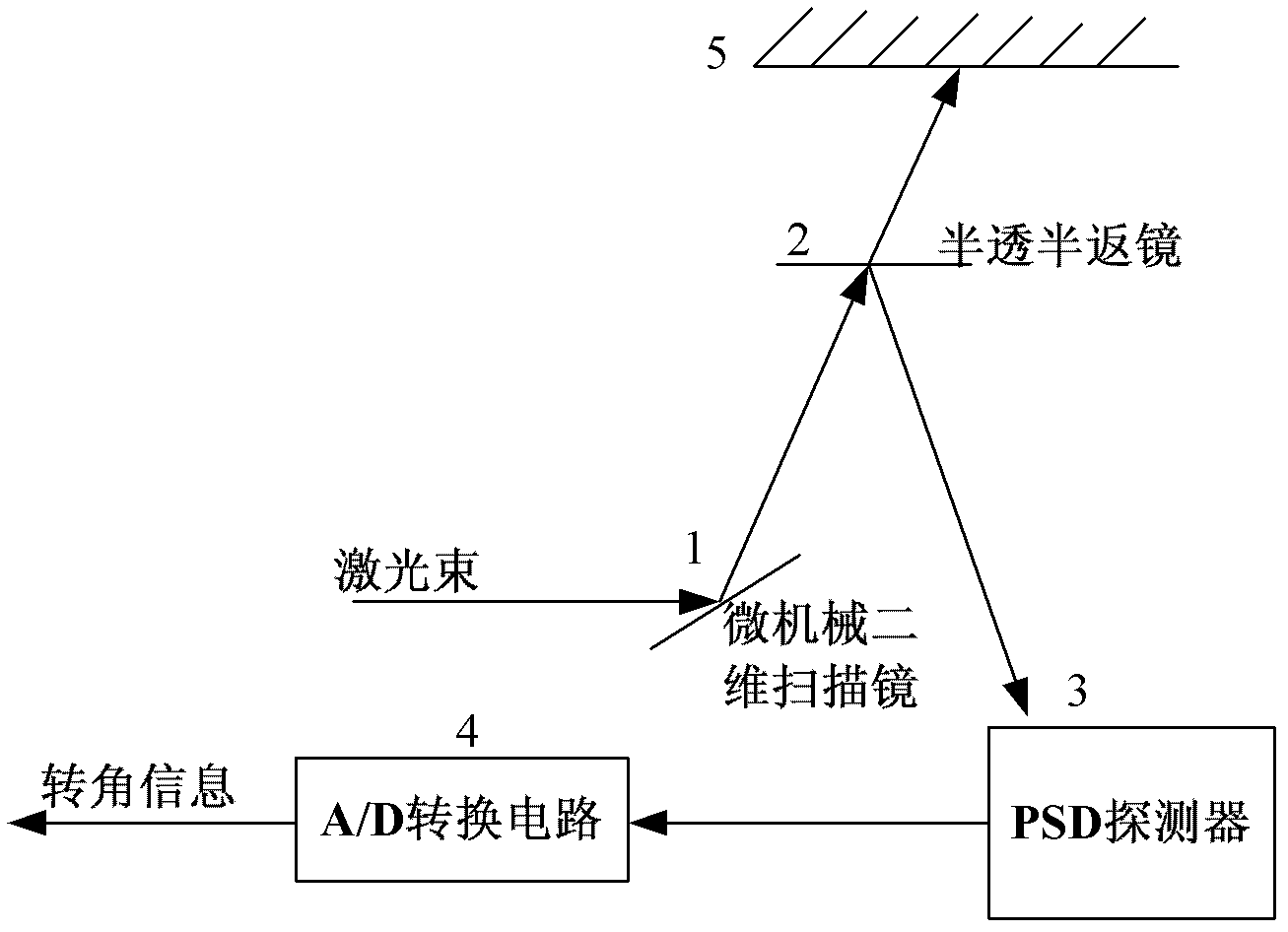

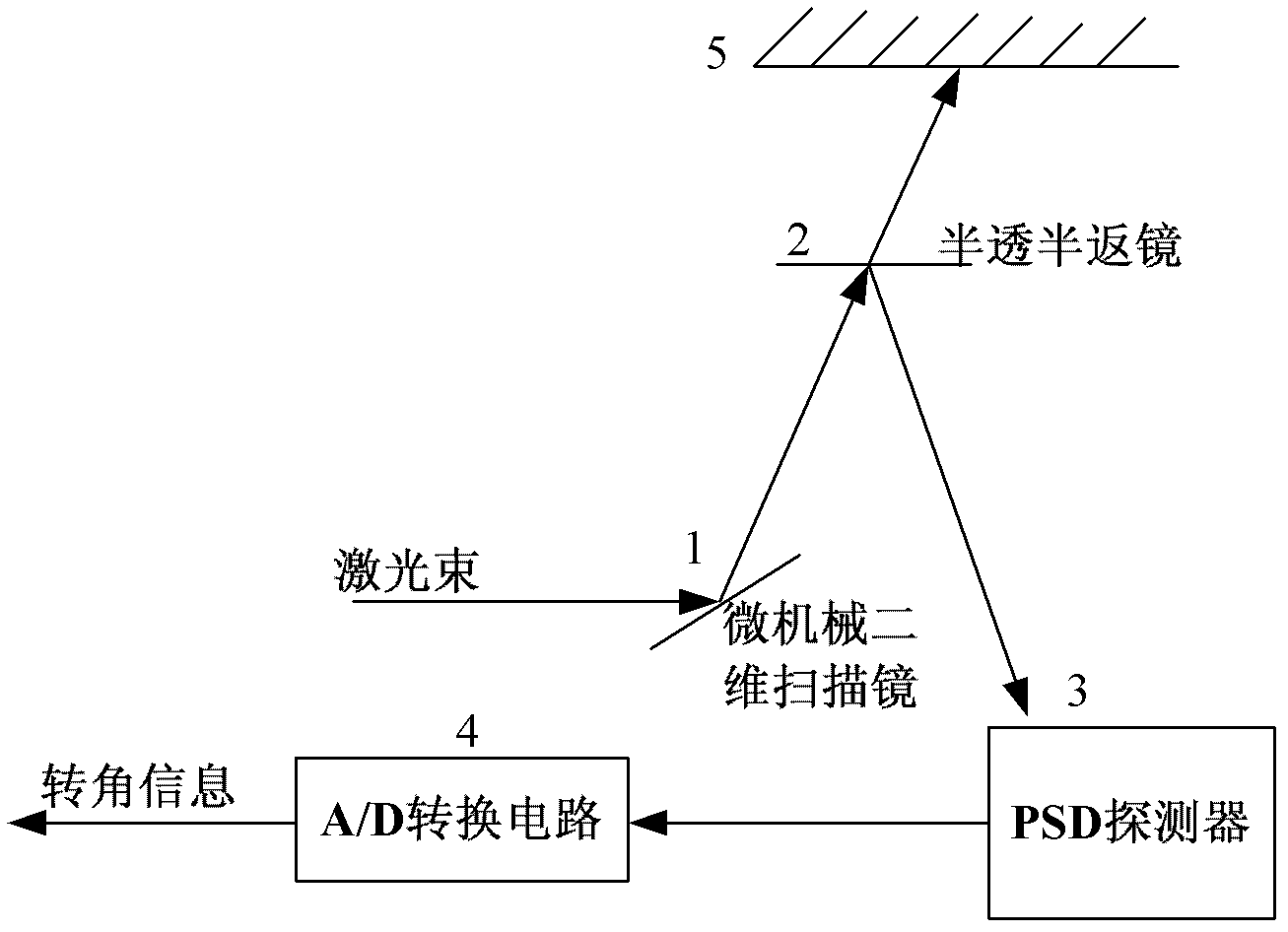

[0015] The specific implementation is as follows: after the laser beam is scanned by 1, it is irradiated on the semi-transparent and half-reflective mirror 2, and the semi-transparent and half-reflective mirror 2 can make 95% of the light beam pass through and irradiate on the object, and the remaining light is reflected to the PSD detection On the device 3, the PSD detector 3 outputs two analog voltage signals after detecting the laser, and the voltage signals respectively represent the position of the laser spot on the PSD detector, and the position coordinates correspond to the scanning angle of the MEMS two-dimensional scanning mirror. The two voltage signals output by the PSD are A / D converted by the A / D conversion circuit 4 and then output as digital signals, that is, the two-dimensional rotation angle measurement of the MEMS is completed.

[0016] Measurement method of the present invention comprises the following steps:

[0017] 1. After the laser beam is scanned by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com