Analysis system for performance detection data of high-end equipment manufacturing material

A technology for detecting data and material properties, which is applied in the field of high-end equipment parts, can solve the problems of time-consuming, labor-intensive and low-efficiency analysis, and achieve the effect of time-saving, labor-saving and high-efficiency analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

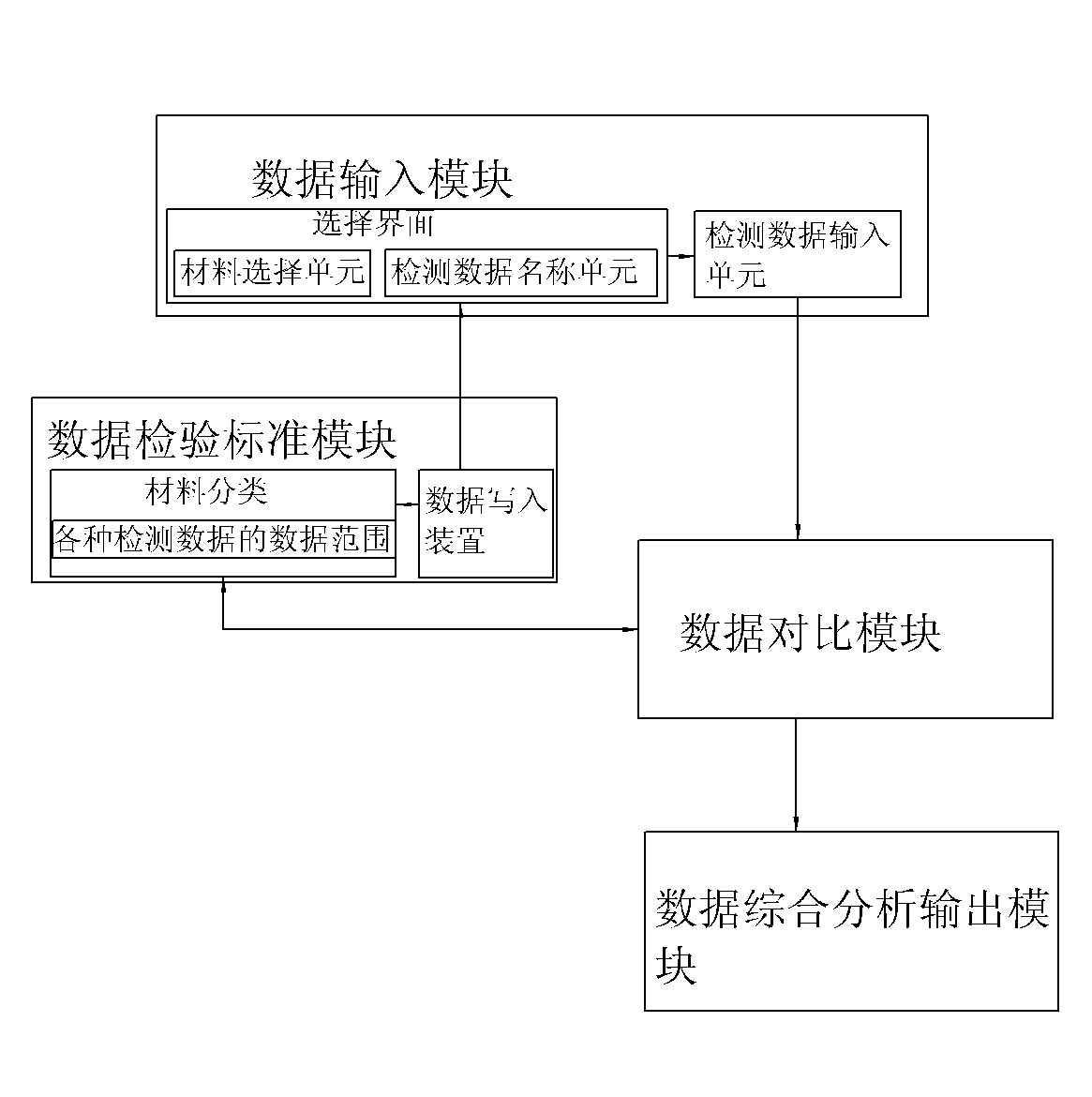

Method used

Image

Examples

specific Embodiment 1

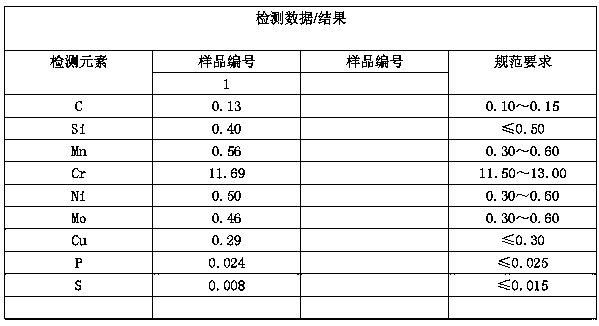

[0020] The chemical composition data analysis of the material whose material grade is 1Cr12 Mo, the chemical composition content data of the material after the instrument detection is as follows:

[0021] The unit of each test data is the content percentage per unit volume, carbon (C): 0.13, silicon (Si): 0.40, manganese (Mn): 0.56, chromium (Cr): 11.69, nickel (Ni): 0.50, molybdenum (Mo): 0.46, copper (Cu): 0.29, phosphorus (P): 0.024, sulfur (S): 0.008;

[0022] On the selection interface of the detection data input module, after the material grade is selected successively as the material of 1Cr12 Mo, the chemical composition content data of the material, the chemical composition content data of the above-mentioned detection are input sequentially, after the input is completed, the detection data input module will detect the data and Its own material information and detection data name are sent to the data comparison module;

[0023] After the data comparison module receive...

specific Embodiment 2

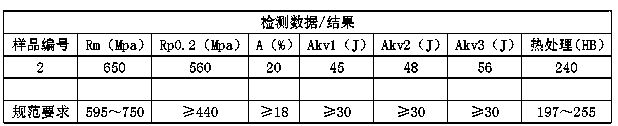

[0027] Concrete embodiment two: the mechanical property data analysis of the material that material trade mark is 1Cr12Mo, the mechanical property data of this material is as follows through instrument detection:

[0028] Tensile strength (Rm): 650Mpa, yield strength (Rp0.2): 560 Mpa, elongation (A): 20%, V-type first impact strength (Akv1): 45J, V-type second impact strength ( Akv2): 48J, V-type third impact strength (Akv3): 56J, heat treatment: 240HB, and the Chinese names of each unit are as follows:

[0029] Mpa: MPa, J: coke, HB: Brinell hardness;

[0030] On the selection interface of the detection data input module, after selecting the material grade of 1Cr12 Mo and the mechanical property data of the material in turn, the mechanical property data of the above-mentioned detected materials are input sequentially. After the input is completed, the detection data input module will test the data and Its own material information and detection data name are sent to the data ...

specific Embodiment 3

[0035] Specific embodiment three: the material grade is the chemical composition data analysis of the material of TC4, and the chemical composition content data of this material is as follows through instrument detection:

[0036] The unit of each test data is the content percentage per unit volume, carbon (C): 0.04, silicon (Si): 0.09, manganese (Mn): 0.13, molybdenum (Mo): 0.09, copper (Cu): 0.07, aluminum (Al): 5.56, zirconium (Zr): 0.02, oxygen (O): 0.18, hydrogen (H): 0.011, iron (Fe): 0.29, tin (Sn): 0.11;

[0037]On the selection interface of the detection data input module, after selecting the material whose material grade is TC4 and the chemical composition content data of the material, input the above-mentioned detected chemical composition content data in sequence. After the input is completed, the detection data input module will send the detection data and other The built-in material information and test data name are sent to the data comparison module;

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com