Magnetic-acoustic surface wave magnetic field sensor and preparation method thereof

A magnetic field sensor and surface wave technology, applied in the direction of the size/direction of the magnetic field, can solve the problems of difficult miniaturization and low magnetic field sensitivity, and achieve the effects of easy integration, high sensitivity, and consistent number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

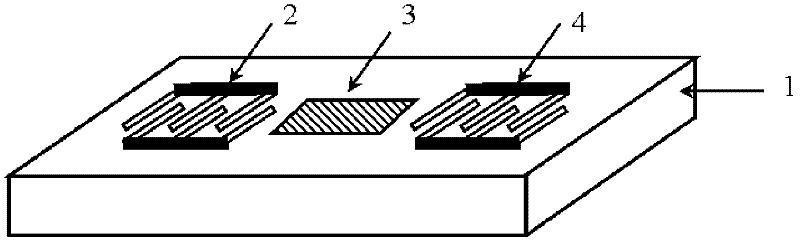

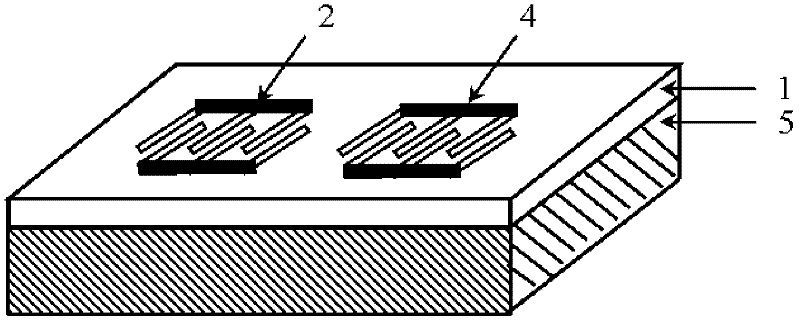

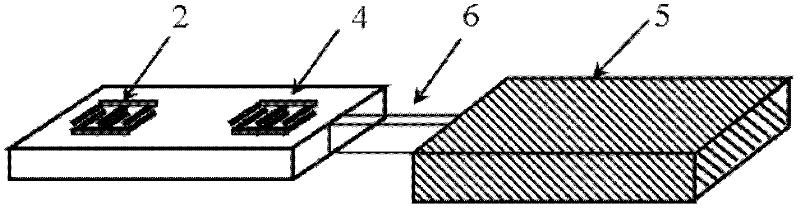

[0021] A method for preparing a magnetoacoustic surface wave magnetic field sensor, comprising the following steps:

[0022] Step 1: On clean Pt / Ti / SiO 2 / Si substrate Pt surface sputtering deposition of piezoelectric film and high temperature annealing of the piezoelectric film. Highly oriented ZnO, PZT, AlN or LiNbO should be used for piezoelectric film 3 Piezoelectric film with a thickness of 1-2 microns.

[0023]Step 2: Deposit a metal chromium buffer layer on the surface of the piezoelectric thin film obtained in step 1 by sputtering. The thickness of the metal chromium buffer layer is controlled at about 20 nanometers. The role of the metal chromium buffer layer is to increase the adhesion between the piezoelectric film and the magnetostrictive film. If the magnetostrictive film is directly sputtered on the surface of the piezoelectric film, it will cause damage to the quality of the piezoelectric film on the one hand, and on the other hand It is also difficult to ob...

specific Embodiment approach 1

[0029] A specific surface wave magnetic field sensor obtained through the above preparation process, the substrate substrate is a quartz substrate, the size is 20 × 10 mm, and the parameters of each component are as follows:

[0030] The piezoelectric film is a C-axis oriented ZnO film with a thickness of 1 micron, the rocking curve FWHM (half width height) of its (002) diffraction peak is 2.8 deg, and the resistivity is >10 9 Ω / cm, surface roughness less than 4nm, piezoelectric coefficient d 33 for

[0031] The magnetostrictive film is 5 μm thick Fe 81 Si 13.5 B 3.5 C 2 Thin film, the magnetostriction coefficient is 35ppm, the coercive force along the direction of easy magnetization is 2Oe, and the remanence ratio> 75%;

[0032] The interdigital transducer is a double-ended interdigital transducer with reflection grids on both sides, with a thickness of 0.8 microns and made of metal aluminum. The finger width and finger spacing of IDs and reflection grids are both 2 μm...

specific Embodiment approach 2

[0035] A specific surface wave magnetic field sensor obtained through the above preparation process, the substrate substrate is a quartz substrate, the substrate size is 20 × 10 mm, and the parameters of each component are as follows:

[0036] The piezoelectric film is PZT (Pb 1.1 (Zr 0.58 Ti 0.42 )O 3 ) film with a thickness of 1 micron, the rocking curve FWHM (half width height) of its (001) diffraction peak is 5.8deg, and the resistivity>10 10 Ω / cm, surface roughness less than 6.5nm, piezoelectric coefficient d 33 for

[0037] The magnetostrictive film is Fe after 5 microns 78 Si 9 B 13 The film has a magnetostriction coefficient of 30ppm, a coercive force of 2.4Oe along the direction of easy magnetization, and a remanence ratio>50%; two layers of 20nm metal copper layers are inserted into the magnetostrictive film;

[0038] The interdigital transducer is a double-ended interdigital transducer with reflection grids on both sides, with a thickness of 0.8 microns ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com