Static mixer for pipeline

A static mixer and mixer technology, which is applied in the directions of fluid mixers, mixers, chemical instruments and methods, can solve the problems of large fluid flow resistance, high manufacturing cost, and high operating energy consumption, and achieve long-distance energy consumption. Low, save the amount of investment, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

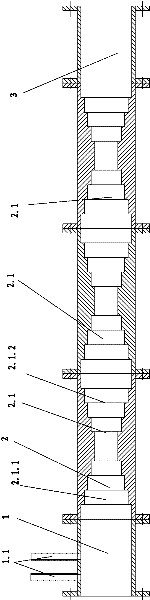

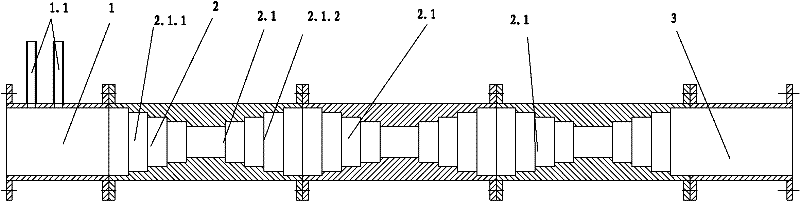

[0017] Such as figure 1 As shown, the present invention includes a mixer pipeline body, and the mixer pipeline body includes a water inlet dosing area 1, a water medicine mixing area 2 and a water outlet area 3; two dosing pipes 1.1 are fixed on the water inlet dosing area 1; The drug mixing area 2 is composed of three sequentially connected combined flow channel areas 2.1, and each combined flow channel area 2.1 includes a tapered flow channel 2.1.1 and a tapered flow channel 2.1.2, the tapered flow channel 2.1. The small end of 1 is docked with the small end of the diverging channel 2.1.2; the converging channel 2.1.1 and the diverging channel 2.1.2 are both frustum-shaped channels, that is, their axial sections are all isosceles trapezoidal, The surfaces of the converging flow channel 2.1.1 and the diverging flow channel 2.1.2 are each provided with a four-stage stepped ring-type agitation structure to prevent the formation of a laminar flow layer on the surface of the flow...

Embodiment 2

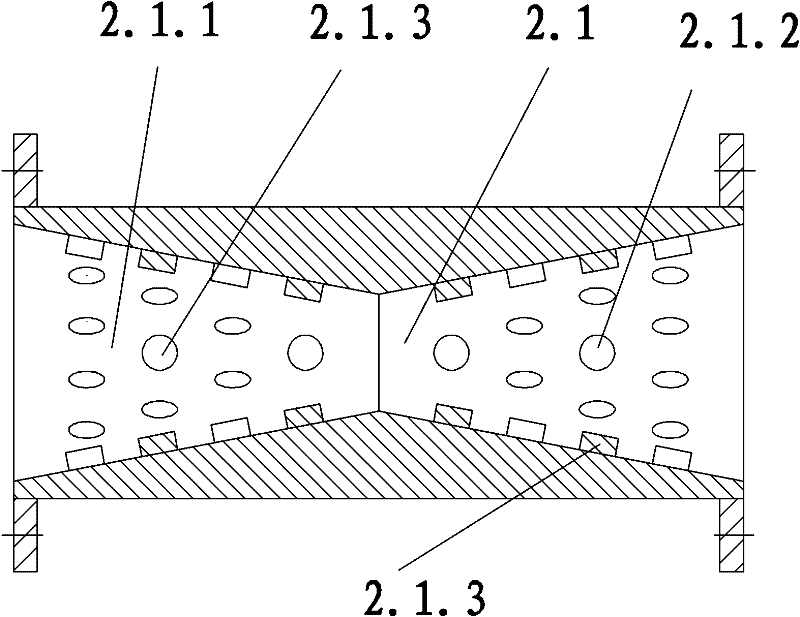

[0019] Such as figure 2 As shown, the structural difference between Embodiment 2 and Embodiment 1 is that some protrusions 2.1 are provided on the surfaces of the converging flow passage 2.1.1 and the diverging flow passage 2.1.2 of the combined flow passage area 2.1 of Embodiment 2. .3 Constitute a turbulent flow structure to prevent the formation of a laminar layer on the surface of the flow channel. These protrusions 2.1.3 form several raised rings on the corresponding flow channel surface along the axis of the flow channel. The same tapered flow channel 2.1 .1 and the protrusions 2.1.3 on two adjacent protrusion rings on the surface of the same diverging channel 2.1.2 are distributed alternately. In this embodiment, the protrusions 2.1.3 are cylindrical protrusions, and each protrusion 2.1.3 is welded together with the surfaces of the tapered flow channel 2.1.1 and the divergent flow channel 2.1.2. In addition to the cylindrical protrusions used in this example, the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com