Method for preparing low-cost high-activity cobalt-based Fischer-Tropsch synthetic catalyst

A cobalt-based Fischer-Tropsch synthesis technology, which is used in catalyst activation/preparation, preparation of liquid hydrocarbon mixtures, chemical instruments and methods, etc. The problem of high cost, to achieve the effect of improving industrial popularization, low methane selectivity, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

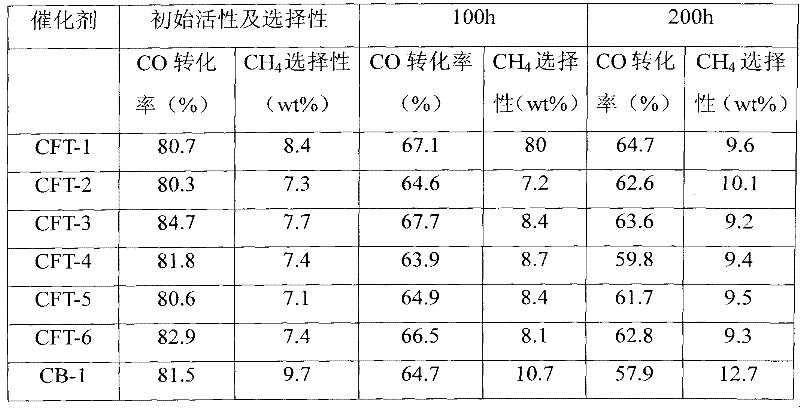

Examples

example 1

[0018] Weigh commercially available silica gel (pore volume is 1.06ml / g, specific surface area is 386.81m 2 / g, the following examples all use the silica gel) 30g, distilled water is added dropwise to initial moistening, and the volume of consumed water is 48ml. The aqueous solution with a sucrose mass concentration of 5% was adjusted to a pH value of 3 with sulfuric acid, and the mass ratio of the silica gel to the mixed solution was 1:4, and the silica gel and the sucrose acidic solution were fully mixed and stirred for 2 hours at a temperature of 60°C. Dry at 60°C for 24 hours, and then bake at 800°C for 10 hours in vacuum or nitrogen atmosphere.

[0019] Based on the final catalyst zirconium content of 1wt%, weigh 1.41g of zirconium nitrate trihydrate, add distilled water to 48g, wait for complete dissolution, add the above-mentioned modified carrier silica gel for impregnation, aging for 3 hours, and dry at 50°C for 24 hours. °C for 10 hours. According to the final cata...

example 2

[0022] Weigh commercially available silica gel, add distilled water dropwise until initial moistening, and the volume of consumed water is 48ml. The aqueous solution with a sucrose mass concentration of 15% was adjusted to a pH value of 2 with hydrochloric acid, and the mass ratio of the silica gel to the mixed solution was 1:9, and the silica gel and the sucrose acidic solution were fully mixed and stirred at a temperature of 70° C. for 3.5 hours. Dry at 100°C for 16 hours, then vacuum bake at 900°C for 8 hours.

[0023]Based on the final catalyst zirconium content of 3wt%, weigh 4.23g of zirconium nitrate trihydrate, add distilled water to 48g, wait for complete dissolution, add the above-mentioned modified carrier silica gel for impregnation, aging for 3 hours, and dry at 150°C for 8 hours. °C for 2 hours. Based on the final catalyst cobalt content of 35wt% and Ni content of 1.5%, the active metal and auxiliary agent Ni are impregnated in two steps. The first step is to w...

example 3

[0025] Weigh commercially available silica gel, add distilled water dropwise until initial moistening, and the volume of consumed water is 48ml. The aqueous solution with a sucrose mass concentration of 20% was adjusted to a pH value of 1 with sulfuric acid, and the mass ratio of the silica gel to the mixed solution was 1:12, and the silica gel and the sucrose acidic solution were fully mixed and stirred for 5 hours at a temperature of 80°C. Dry at 120°C for 8 hours, then vacuum bake at 1000°C for 4 hours.

[0026] Based on the final catalyst zirconium content of 2wt%, weigh 2.82g of zirconium nitrate trihydrate, add distilled water to 48g, wait for complete dissolution, add the above-mentioned modified carrier silica gel for impregnation, aging for 3 hours, and dry at 80°C for 12 hours. °C for 4 hours. According to the final catalyst cobalt content 20wt%, Ni content 1%, weigh 29.64g of cobalt nitrate hexahydrate and nickel nitrate hexahydrate 1.48g, add distilled water to 48...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com