Dry sieved material, and average particle size measuring method and sieving device thereof

A technology of screening device and average particle size, which is applied in the direction of measuring devices, analytical materials, chemical instruments and methods, etc., can solve the problem of gypsum particles being difficult to disperse, and achieve the effects of reducing experimental errors, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

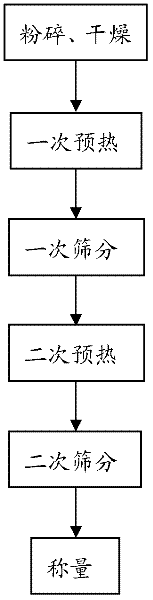

Method used

Image

Examples

Embodiment 1

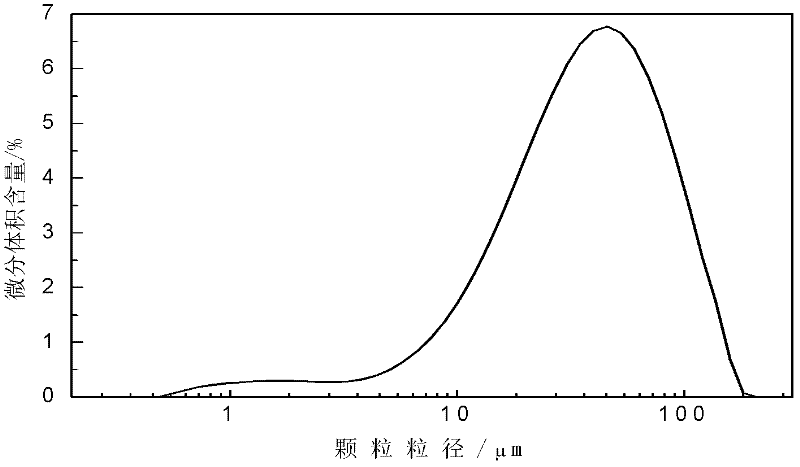

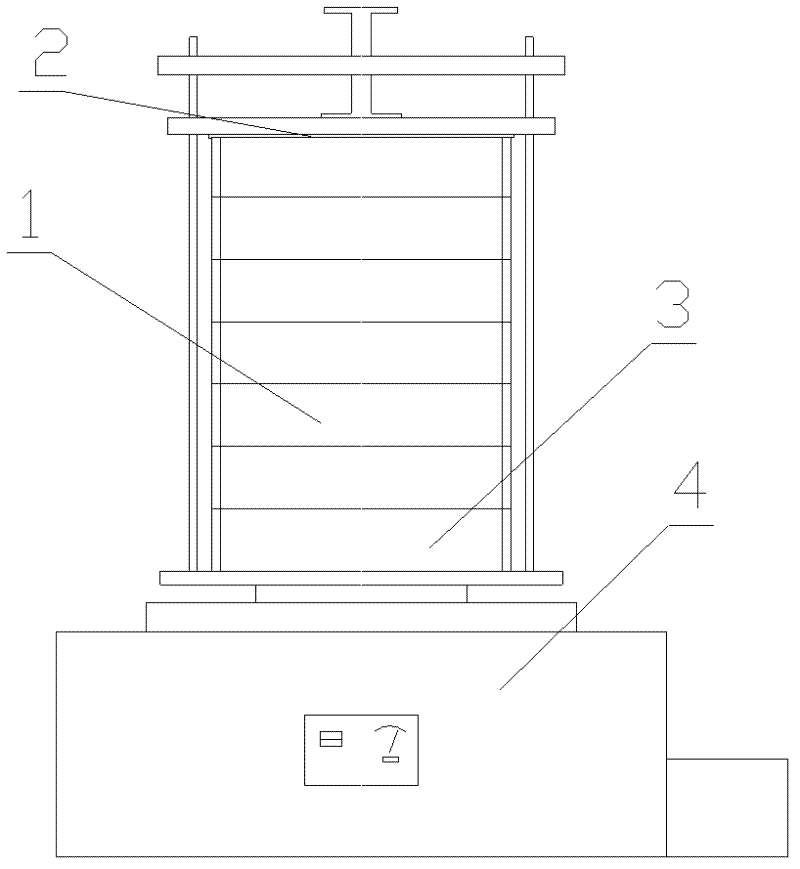

[0021] Use the above-mentioned sieving device to lightly press and crush the agglomerated particles in the gypsum, and keep the temperature at 45°C for 15 hours, then cool to room temperature in a desiccator. Accurately weigh 35-45g of gypsum on the top sieve surface of standard sieve 1 wrapped with thermal insulation material, and cover with top cover 2. Place the standard sieve and the weighed gypsum at 50° C. to preheat for 50 minutes, and sieve on the vibrating sieve machine 4 for 10 minutes; the ambient air humidity of the vibrating sieve is 65%. After the sieving, put the standard sieve 1 and the gypsum sample at 50° C. to preheat for 40 minutes again, and sieve on the vibrating sieve machine 4 for 10 minutes. After the sieving, the gypsum particles of each layer of the sieve surface were collected on weighing paper, and the mass of the gypsum particles of each layer of the sieve surface was accurately weighed, and sieved three times in parallel. The measurement results ...

Embodiment 2

[0025] Using the same screening device as in Example 1, lightly press and crush the agglomerated particles in the gypsum, and keep the temperature at 45° C. for 15 hours, then cool to room temperature in a desiccator. Accurately weigh 35-45g of gypsum on the top sieve surface of standard sieve 1 wrapped with thermal insulation material. Standard sieve 1 from top to bottom, the hole size is 0.075, 0.063, 0.053, 0.045, 0.037, 0.030mm and the bottom tray 3, cover the top cover 2. Place the standard sieve 1 and the weighed gypsum at 50°C to preheat for 50 minutes, and sieve on the vibrating sieve machine 2 for 10 minutes; the ambient air humidity of the vibrating sieve is 80%; Preheat again at ℃ for 40 minutes, and sieve on vibrating screen machine 4 for 10 minutes. After the sieving, collect the gypsum particles of each layer of sieve surface on weighing paper, accurately weigh the mass of gypsum particles of each layer of sieve surface, and sieve in parallel. Three times, the m...

Embodiment 3

[0029] Using the same screening device as in Example 1, lightly press and crush the agglomerated particles in the gypsum, and keep the temperature at 45° C. for 15 hours, then cool to room temperature in a desiccator. Accurately weigh 35-45g of gypsum to wrap the top screen surface of standard sieve 1 of thermal insulation material. Cover 2. Place the standard sieve and the weighed gypsum at 50°C to preheat for 50 minutes, and sieve on the vibrating sieve machine 4 for 10 minutes; the ambient air humidity of the vibrating sieve is 65%; On weighing paper, accurately weigh the mass of gypsum particles on each layer of sieve surface, and sieve in parallel three times. The measurement results are shown in Table 3. The average particle sizes of gypsum are 0.0368mm, 0.042mm and 0.042mm respectively.

[0030] Table 3 Example 3 The mass of desulfurized gypsum on the sieve surface of each layer / g

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com