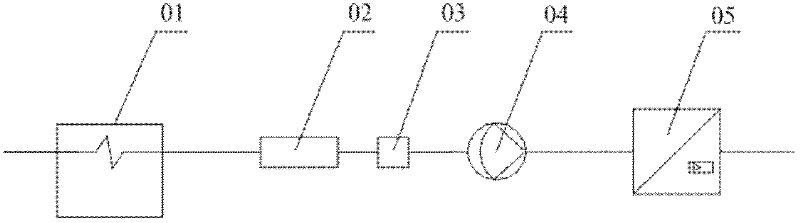

Pretreatment system

A pretreatment and shell technology, which is applied in the field of flue gas purification, can solve problems such as increased system maintenance and maintenance costs, air leakage in gas lines, joint solenoid valves, and analyzer corrosion, reducing maintenance costs and reducing maintenance costs. amount, the effect of preventing corrosion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] CEMS: Automatic flue gas monitoring system, which is mainly used to continuously detect the concentration and total emission of gaseous pollutants and particles emitted by fixed pollution sources, and transmit the information to the competent department in real time.

[0025] PVC: PVC material is polyvinyl chloride, which is one of the largest plastic products in the world; it is cheap, widely used, has non-flammability, high strength, weather resistance and excellent geometric stability; it is resistant to oxidants, Both reducing agents and strong acids are very resistant.

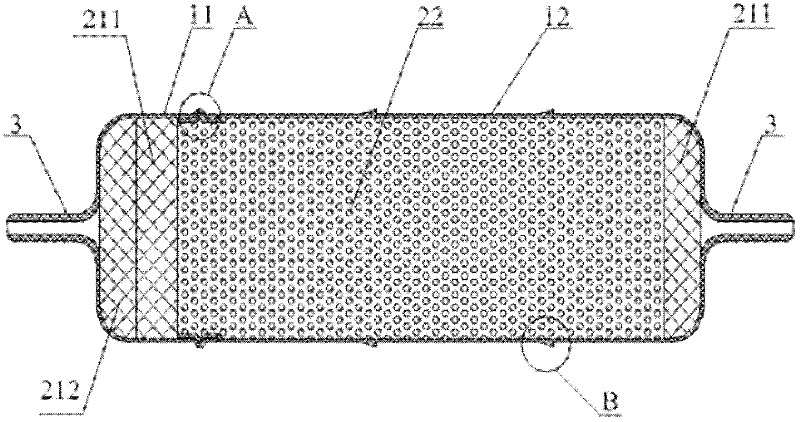

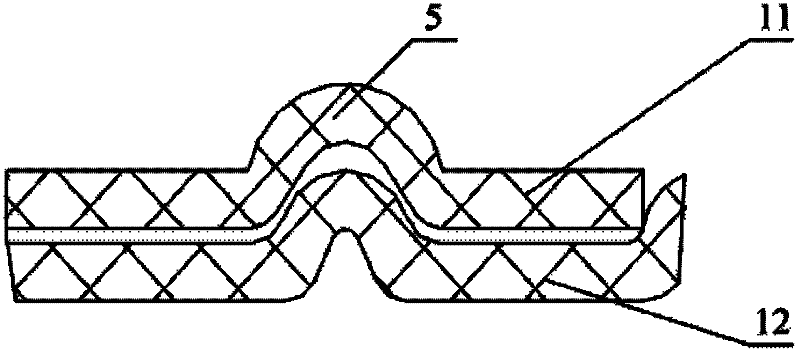

[0026] The core of the present invention is to provide a pretreatment system, which can not only dehumidify and dedust the flue gas, but also effectively remove and absorb sulfur trioxide, so as to prevent the acid mist formed by sulfur trioxide from affecting the CEMS system. Corrosion and damage, reducing the amount of maintenance and maintenance costs of the system.

[0027] In order to enable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com