Stable welding method for argon arc welding of high-silicon-content silicon steel

A welding method and argon arc welding technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of affecting the normal and stable running of the unit, low production efficiency, broken belt at the welding seam, etc., and achieve stable and reliable product quality. , The effect of low production cost and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

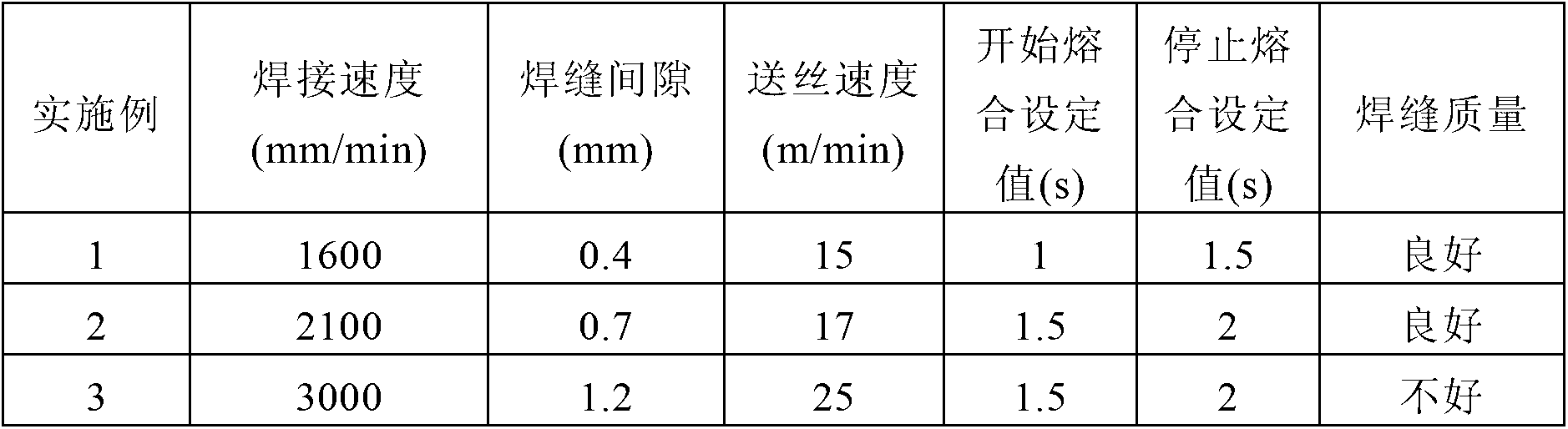

Embodiment 3)

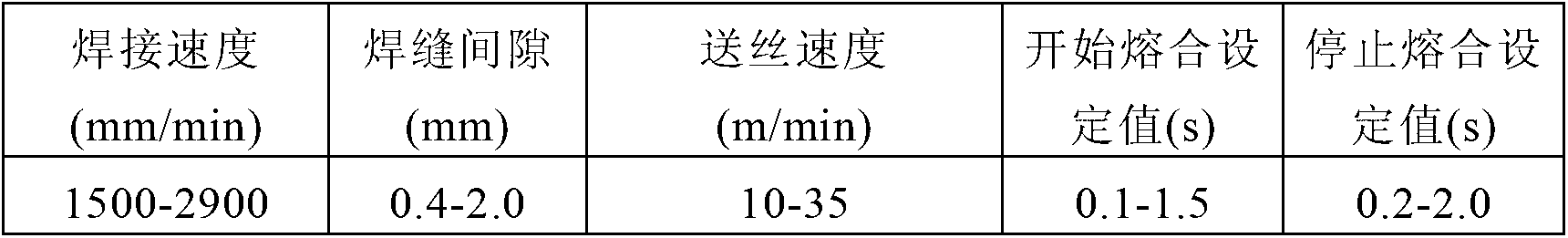

[0027] Table 2. Influence of different welding process parameters on weld quality

[0028]

[0029] The invention overcomes the technical problem of stably welding high-silicon-content electrical steel with an argon arc welding process. It can be completely applied to other similar high-silicon material production units with argon arc welding machines, which broadens the welding field of argon arc welding, and realizes the production of high-value-added silicon steel with high silicon content with low-cost argon arc welding machines. The cost can be greatly reduced, and it has a very high promotion value.

PUM

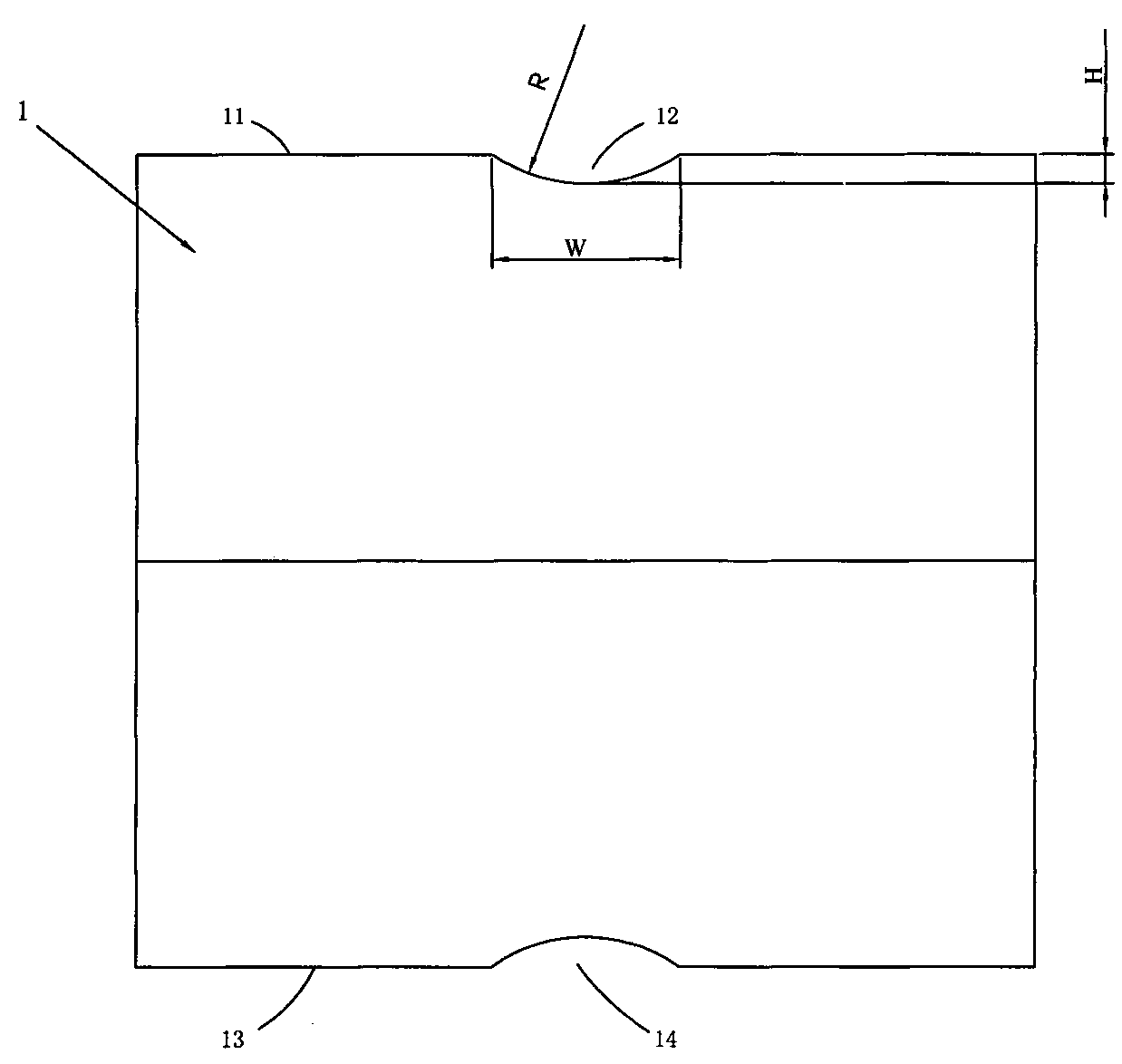

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com