Treatment method and system of water-based oil-containing solution

A treatment method and a treatment system technology, applied in the field of water-based oily solution treatment methods and treatment systems, can solve the problems of unable to form solid salts for transportation and landfill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

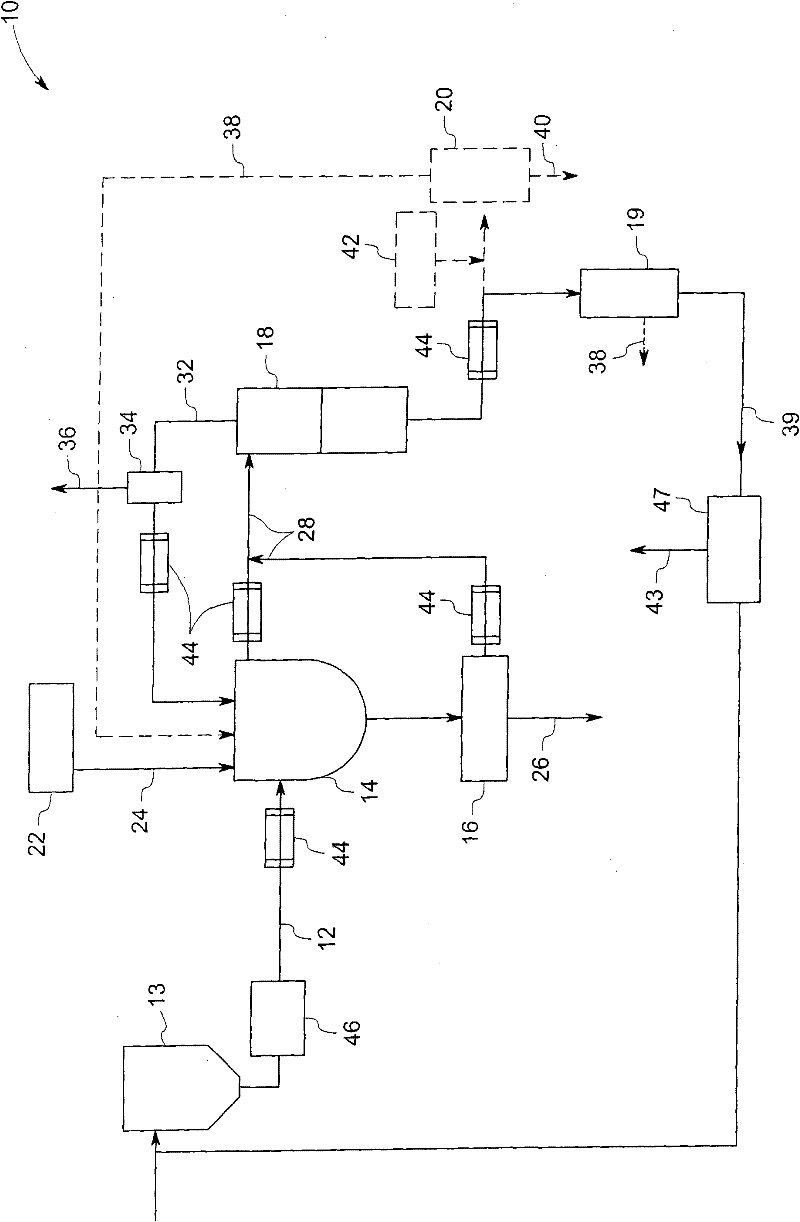

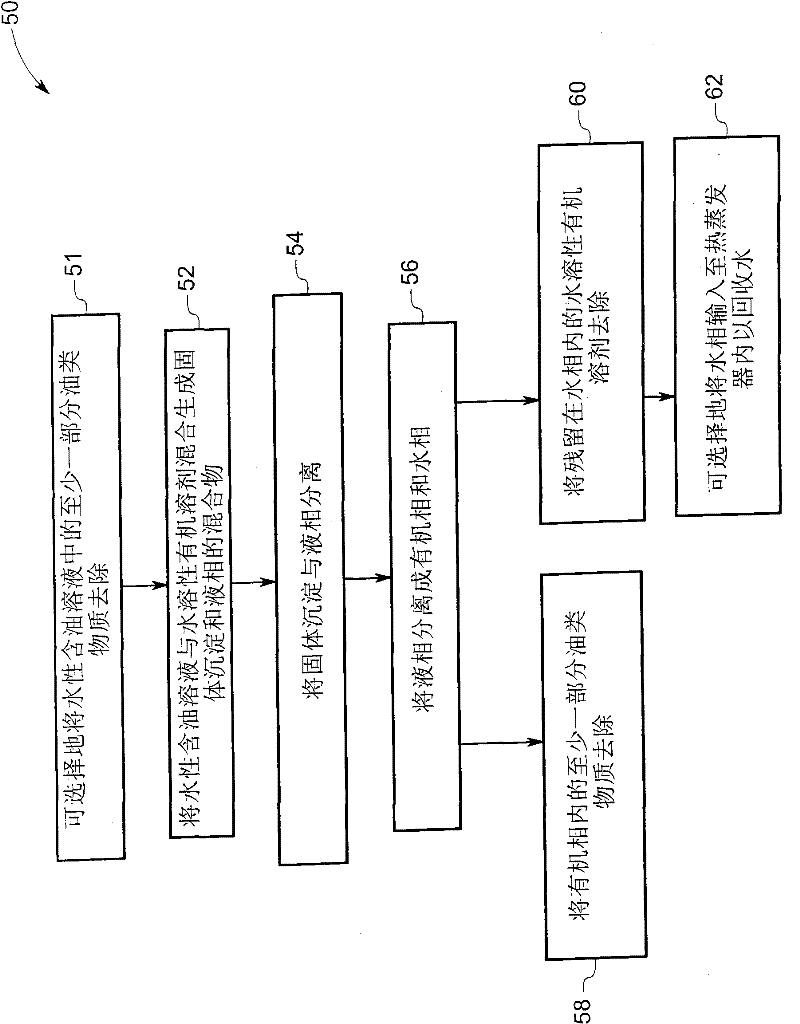

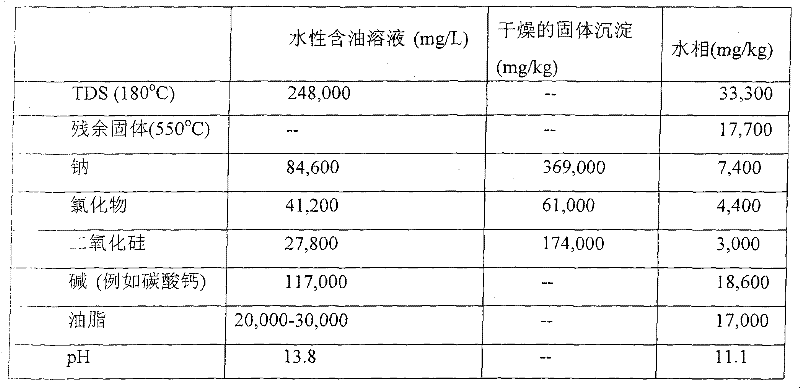

[0011] figure 1 A treatment system 10 for an aqueous oily solution 12 is illustrated, in accordance with one embodiment of the present invention. The aqueous oily solution 12 refers to a saline solution containing oil, grease or other types of oily substances. The aqueous oily solution 12 includes certain amounts of various salts. These salts include, but are not limited to, halides of Sodium, Calcium, Barium, Strontium and Radium; Sodium, Potassium, Magnesium, Calcium, Barium, Bicarbonates of strontium and radium; Silicates of sodium, potassium, magnesium and radium; Selenites; Selenates; Sodium, potassium, magnesium, calcium, Selenides of barium, strontium and radium; selenide salts of phosphorus including monoselenide, disselenide, triselenide and pentaselenide Salts); Selenium Halide Salts including Selenium Monohalide, Selenium Tetrahalide; Selenium Monobromide; Selenium Tetrabromide; Phosphates and Borides of Sodium, Potassium, Magnesium, Calcium, Barium, Strontium an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com