Method for purifying 1-octylene from Fischer-Tropsch synthetic oil products

A technology of Fischer-Tropsch synthesis and octene, applied in distillation purification/separation, organic chemistry, azeotropic distillation, etc., can solve complex problems, achieve scientific design, reduce solvent ratio, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

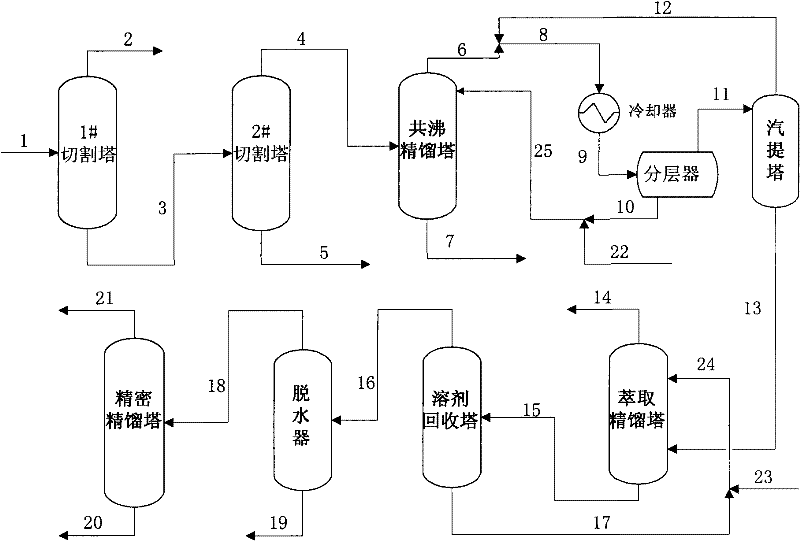

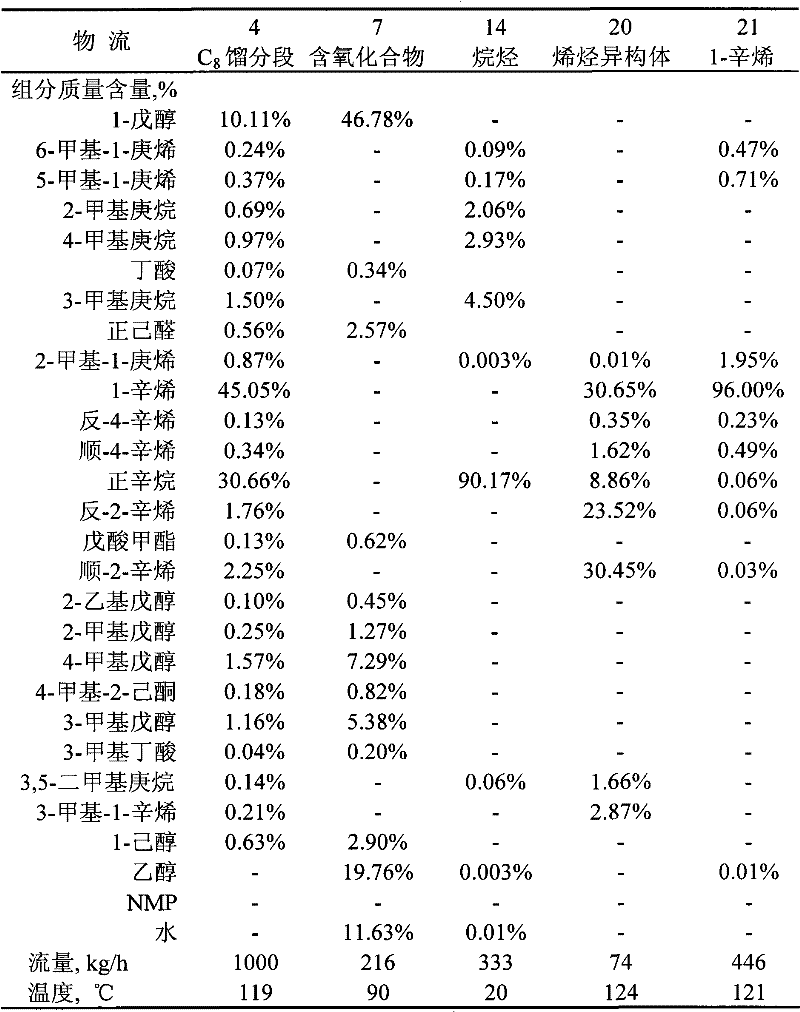

[0077] According to this embodiment figure 1 The process shown is carried out.

[0078] Make the Fischer-Tropsch synthetic light distillate stream 1 enter the 1# cutting tower that the number of theoretical plates is 35, the reflux ratio is 4, and the feeding position is 19 plates (from top to bottom, the same below), from the 1# cutting tower At the end, stream 3 is obtained as C 8 + (including C 8 ) fraction, the purity reaches 99.95%, and the recovery rate reaches 99.97%;

[0079] The C 8 + The fraction enters the 2# cutting tower with a theoretical plate number of 35, the reflux ratio is 4, and the feeding position is 19 plates, and C can be obtained from the top of the tower. 8 Component stream 4;

[0080] C 8 The fraction enters an azeotropic rectification tower with a theoretical plate number of 20. In this embodiment, the heterogeneous azeotropic rectification process is selected. The entrainer is a binary mixed solvent of ethanol and water containing 86% ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com