Loaded metallocene catalyst and preparation method thereof

A technology of metallocene catalysts and metallocene compounds, applied in the field of supported metallocene catalysts and their preparation, can solve the problems of low catalytic activity and achieve the effects of high catalytic activity, high catalytic activity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] According to the preparation method of the present invention, the types of the carrier, the alkylaluminoxane and the metallocene compound have been described above, and will not be repeated here.

[0046] The method for loading the alkylaluminoxane and the metallocene compound on the carrier may be various loading methods known in the art, such as dipping and spraying. The method of impregnation can make the solution more fully enter the pores on the carrier, so impregnation is preferred in the present invention.

[0047] The method for preparing the above-mentioned supported metallocene catalyst of the present invention further comprises heating the carrier at a temperature of 300-500°C for 5-20 hours under the protection of an inert gas before loading the alkylaluminoxane .

[0048] The method for preparing the above-mentioned supported metallocene catalyst of the present invention, for example: may comprise the following steps:

[0049] (1) Thermal activation step,...

Embodiment 1

[0057] This example is used to illustrate the supported metallocene catalyst and its preparation method according to the present invention.

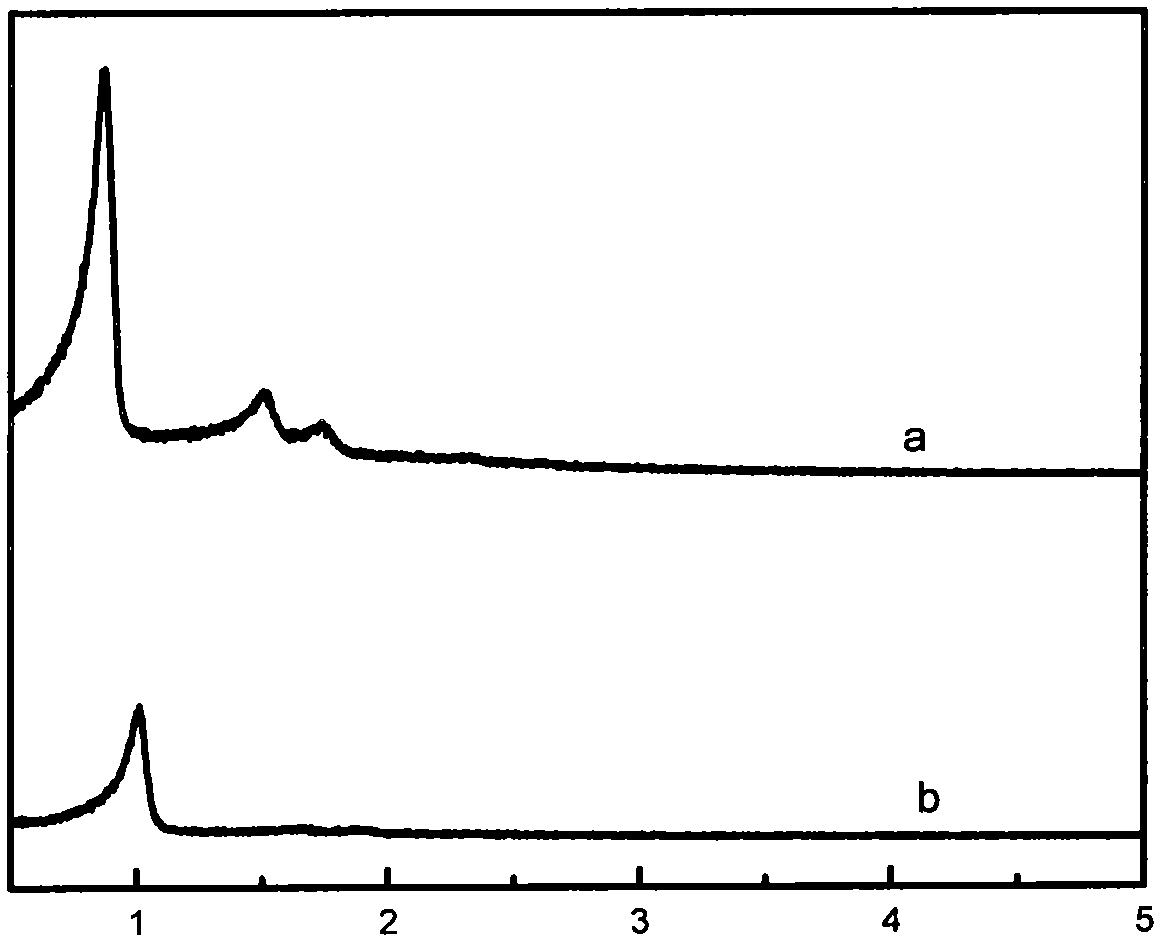

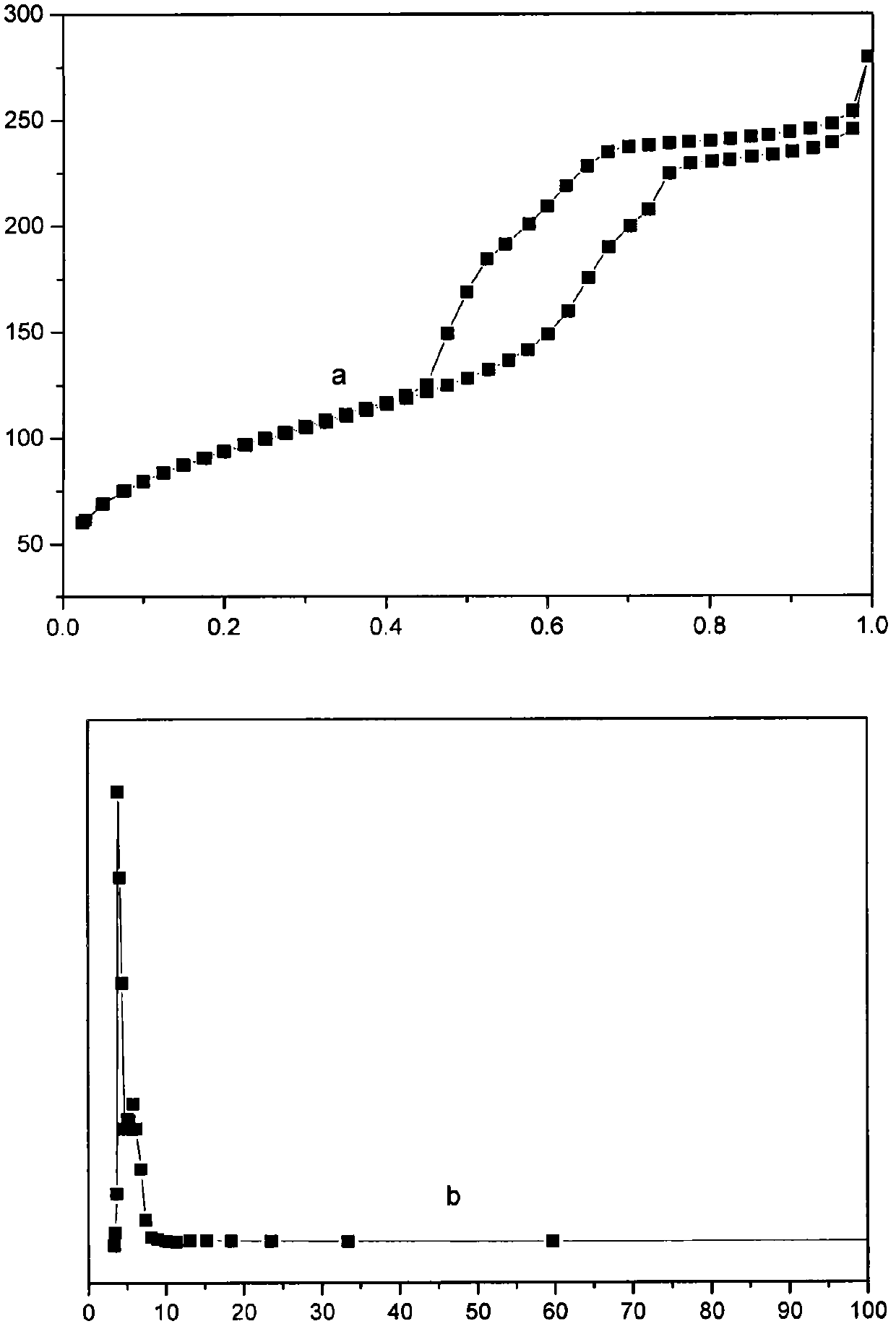

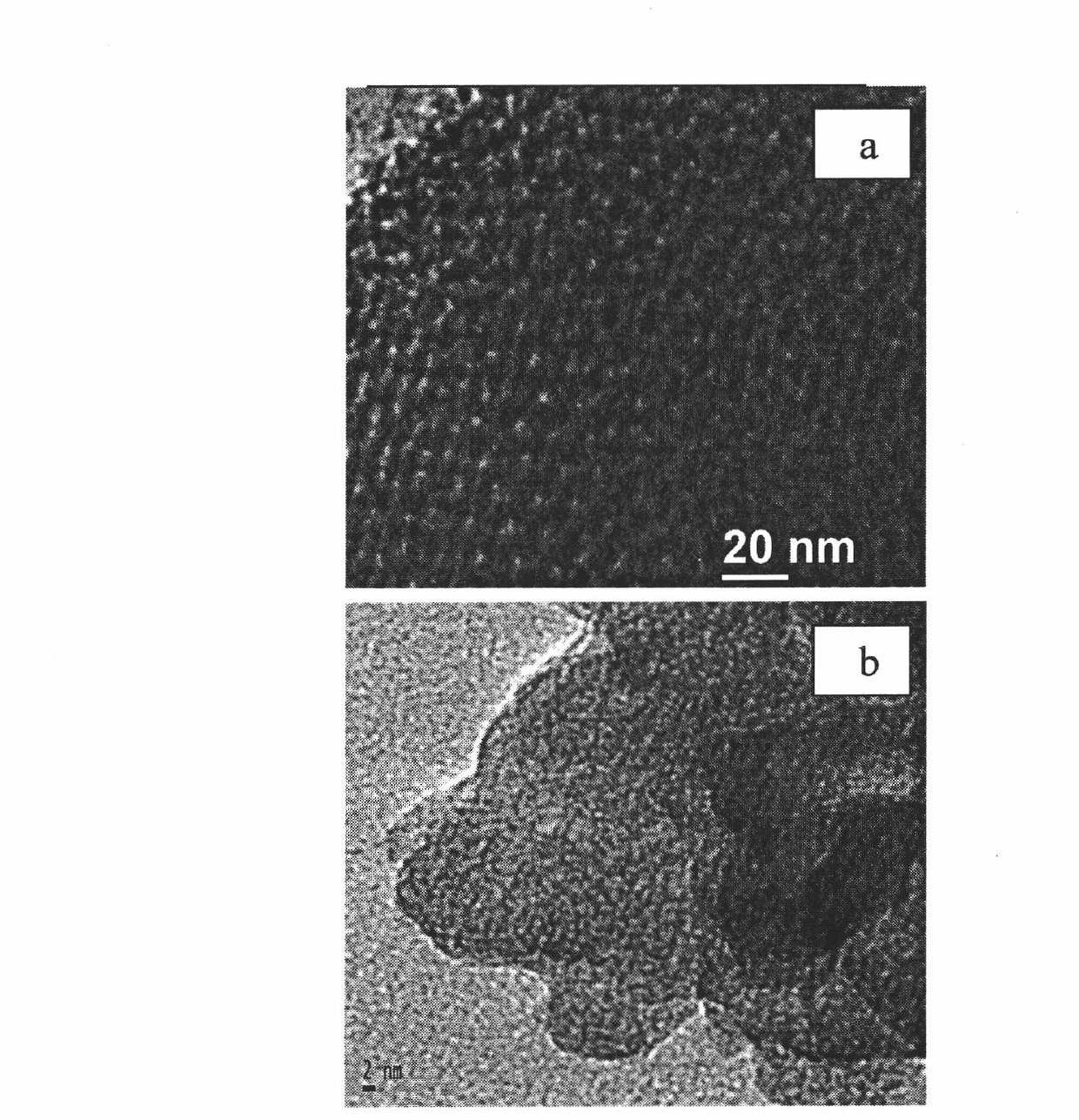

[0058] 1) The rod-shaped mesoporous material SBA-15 (commercially purchased from Changchun Jilin University High-tech Co., Ltd., the length of the rod is 30-100 microns, and its pore structure parameters are shown in Table 1) was calcined at 400 ° C for 10 hour (thermal activation), remove hydroxyl group and residual moisture, obtain the rod-shaped mesoporous material after thermal activation;

[0059]2) Transfer 0.4 g of the thermally activated rod-shaped mesoporous material to a 250 ml glass reactor fully replaced by nitrogen, add 10 ml of refined toluene, methyl aluminoxane (MAO, commercially available from Albemarle, USA) 0.47 g of auxiliary agent was stirred at 50° C. for 4 hours. After completion, wash three times with 20 ml of hexane, and finally dry the solid with nitrogen to obtain a methylaluminoxane / SBA-15 complex carrier (MA...

experiment Embodiment 1

[0070] This experimental example is used to illustrate the catalytic activity of the supported catalyst according to the present invention.

[0071] In a 2-liter stainless steel autoclave, replace three times with nitrogen and ethylene, then add 200 milliliters of hexane solvent, raise the temperature of the kettle to 80 ° C, and then add 800 milliliters of hexane solvent. With the addition of hexane, the 2 ml of 1 mol / L triethylaluminum (TEA) hexane solution was added, followed by 65.5 mg of SBA-15-BU-1, ethylene was introduced to raise and maintain the pressure to 1.0 MPa, and the reaction was carried out at 70°C for 1 hour. After the end of the polymerization reaction, the polyethylene particle powder was collected and weighed to obtain 421 grams. The efficiency of the catalyst was 6427gPE / (gcat h)(8.4×10 7 gPE / (mol Zr h)), the bulk density (BD) of polyethylene is 0.326g / ml, the melt index: MI 2.16 = 0.061 g / 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com