Manufacturing method of nano carbon black through in-situ polyethylene grafting

A technology of nano-carbon black and in-situ grafting, which is applied in the field of polyolefin modification, can solve the problems of easy decomposition and large side effects, and achieve the effect of no solvent, low cost and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

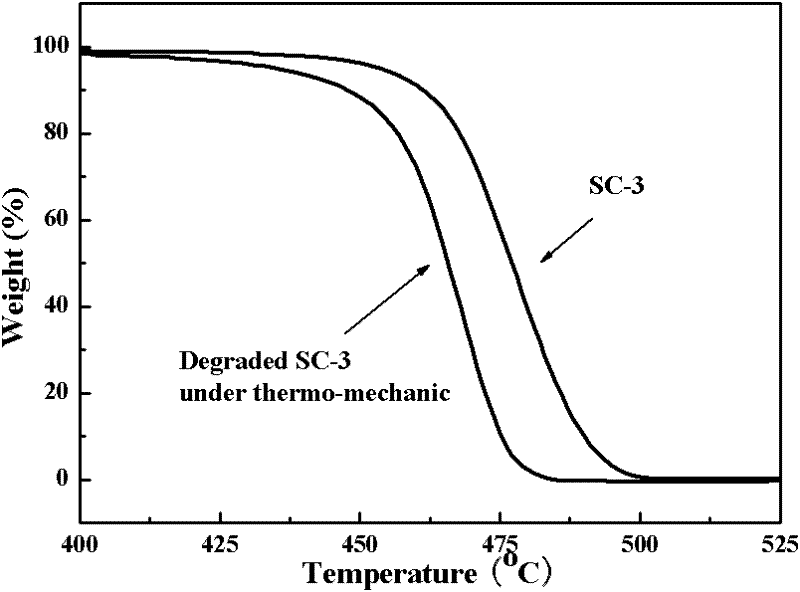

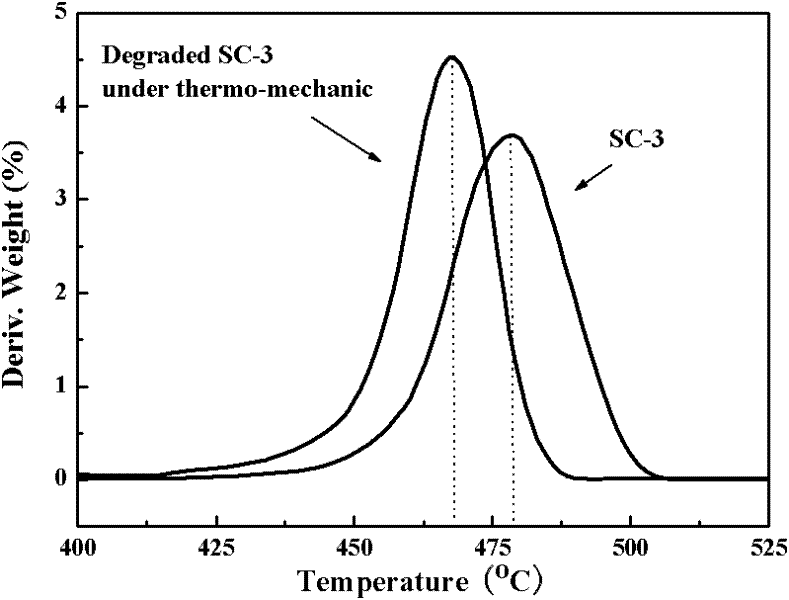

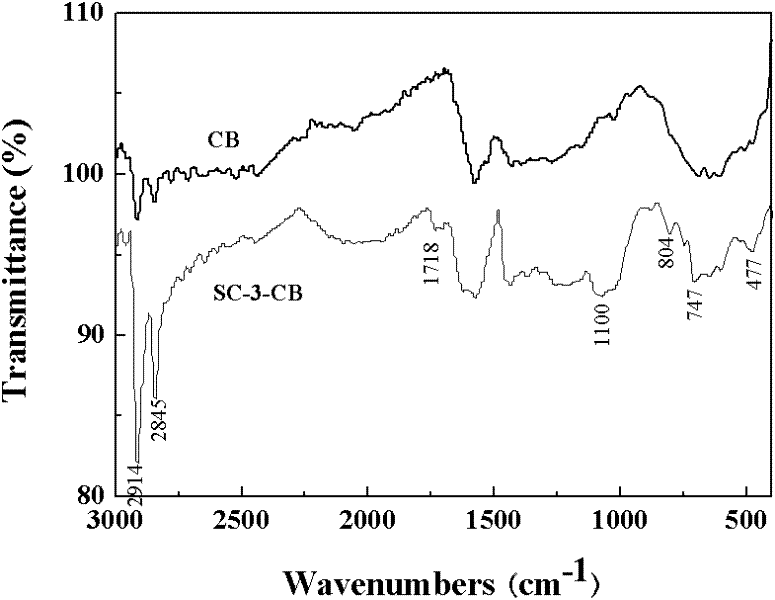

[0028] Graft nano-carbon black using polyethylene: 160g of nano-carbon black, high-density polyethylene SC-332g.

[0029] Nano-carbon black and polyethylene were blended in HAAKE torque rheometer at 140°C, the screw speed was 100rpm, and the blending time was 15min. Under these conditions, polyethylene SC-3 was grafted with nano-carbon in situ black.

[0030] In order to characterize the grafted nano-carbon black, it is necessary to remove the unreacted polyethylene in the system, and the pure grafted nano-carbon black is obtained by the following method: the reactant of the above-mentioned nano-carbon black and polyethylene is dissolved in xylene , after stirring and refluxing at 130-140°C for at least 72 hours, place the dispersion in a high-speed centrifuge (Beijing Medical Centrifuge Factory) and settle for 20 minutes, pour the upper layer solution, and redisperse the settled nano-carbon black in xylene In the solution, centrifugation was carried out until no polyethylene...

Embodiment 2

[0035] Graft nano-carbon black using polyethylene: 160g of nano-carbon black, 32g of high-density polyethylene pipe material DBGB2480H.

[0036] Nano-carbon black and polyethylene were blended in HAAKE torque rheometer at 140 ° C, the screw speed was 100 rpm, and the blending time was 15 min. Under these conditions, polyethylene DBGB2480H was grafted with nano-carbon black in situ.

[0037] In order to characterize the grafted nano-carbon black, it is necessary to remove the unreacted polyethylene in the system, and the pure grafted nano-carbon black is obtained by the following method: the reactant of the above-mentioned nano-carbon black and polyethylene is dissolved in xylene , after stirring and refluxing at 130-140°C for at least 72 hours, place the dispersion in a high-speed centrifuge (Beijing Medical Centrifuge Factory) and settle for 20 minutes, pour the upper layer solution, and redisperse the settled nano-carbon black in xylene In the solution, centrifugation was ca...

Embodiment 3

[0040]Graft nano-carbon black using polyethylene: 160g of nano-carbon black, 704232g of linear low-density polyethylene.

[0041] Nano-carbon black and polyethylene were blended in HAAKE torque rheometer at 140°C, the screw speed was 100rpm, and the blending time was 15min. Under these conditions, polyethylene 7042 was grafted with nano-carbon black in situ.

[0042] In order to characterize the grafted nano-carbon black, it is necessary to remove the unreacted polyethylene in the system, and the pure grafted nano-carbon black is obtained by the following method: the reactant of the above-mentioned nano-carbon black and polyethylene is dissolved in xylene , after stirring and refluxing at 130-140°C for at least 72 hours, place the dispersion in a high-speed centrifuge (Beijing Medical Centrifuge Factory) and settle for 20 minutes, pour the upper layer solution, and redisperse the settled nano-carbon black in xylene In the solution, centrifugation was carried out until no polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com