Felodipine pharmaceutical composition based on dry process granulation

A dry granulation technology for felodipine, which is applied in the pharmaceutical field to achieve the effects of reduced production energy consumption, enhanced quality control and cost savings, and a wide range of granulation process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of 2.5mg Felodipine Tablets

[0034] components

[0035] Felodipine was micronized together with lactose monohydrate (premixed) and pulverized to an average particle size of 30 μm, d(0.9)=85.2 μm. Mix with other internally added materials lactose monohydrate and polyethylene glycol for 15 minutes, then add the internal lubricant glyceryl behenate and mix for 3 minutes. Dry granulation with a roller compactor. Add croscarmellose sodium and added lactose monohydrate and mix for 5 minutes, then add additional glyceryl behenate and mix for 3 minutes. Tablet to obtain the desired product.

Embodiment 2

[0037] Preparation of 2.5mg Felodipine Tablets

[0038] components

Prescription amount (mg / tablet)

percentage

Felodipine

2.5

1.25%

Lactose monohydrate (premixed)

20

10.0%

polyethylene glycol

8

4.0%

Lactose monohydrate (added)

78

39.0%

Microcrystalline Cellulose (Added)

20.3

10.15%

Glyceryl Behenate (Added)

1

0.50%

Lactose monohydrate (additional)

20

10.0%

Microcrystalline Cellulose (Extra)

40

20.0%

Croscarmellose sodium (additional)

10

5.0%

Glyceryl Behenate (additional)

0.2

0.10%

total

200

100%

[0039] Preparation Process:

[0040] Felodipine was micronized together with lactose monohydrate, and pulverized to an average particle size of 56 μm, d(0.9)=126.2 μm. Then mix with other internally added materials polyethylene glycol, microcrystalline ce...

Embodiment 3

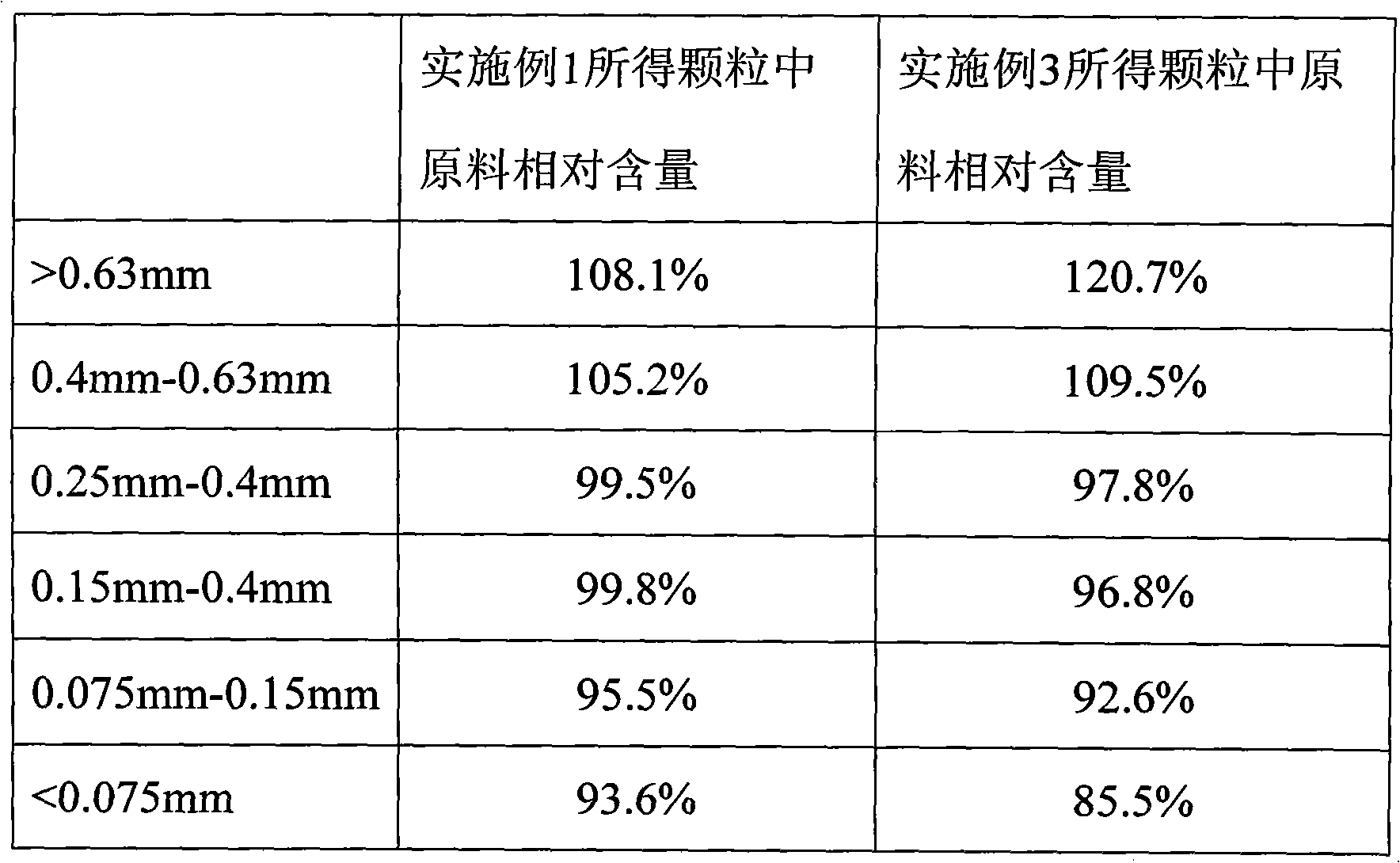

[0041] Embodiment 3 (comparative example)

[0042] Adopt the same prescription as Example 1, but do not carry out micronization.

[0043] components

Prescription amount (mg / tablet)

percentage

Felodipine

2.5

1.25%

10

5.0%

Lactose monohydrate (added)

90

45.0%

Lactose monohydrate (additional)

52.3

26.15%

Glyceryl Behenate (Added)

1

0.5%

Microcrystalline Cellulose (Extra)

40

20.0%

Croscarmellose sodium (additional)

4

2.0%

Glyceryl Behenate (additional)

0.2

0.1%

total

200

100%

[0044] Preparation Process:

[0045] The felodipine internal addition material lactose monohydrate and polyethylene glycol were mixed for 15 minutes, and then the internal lubricant glyceryl behenate was added and mixed for 3 minutes. Dry granulation with a roller compactor. Add additional lactose monoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com